Grey titanium dioxide nano-material, as well as preparation method and application thereof

A technology of titanium dioxide and nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

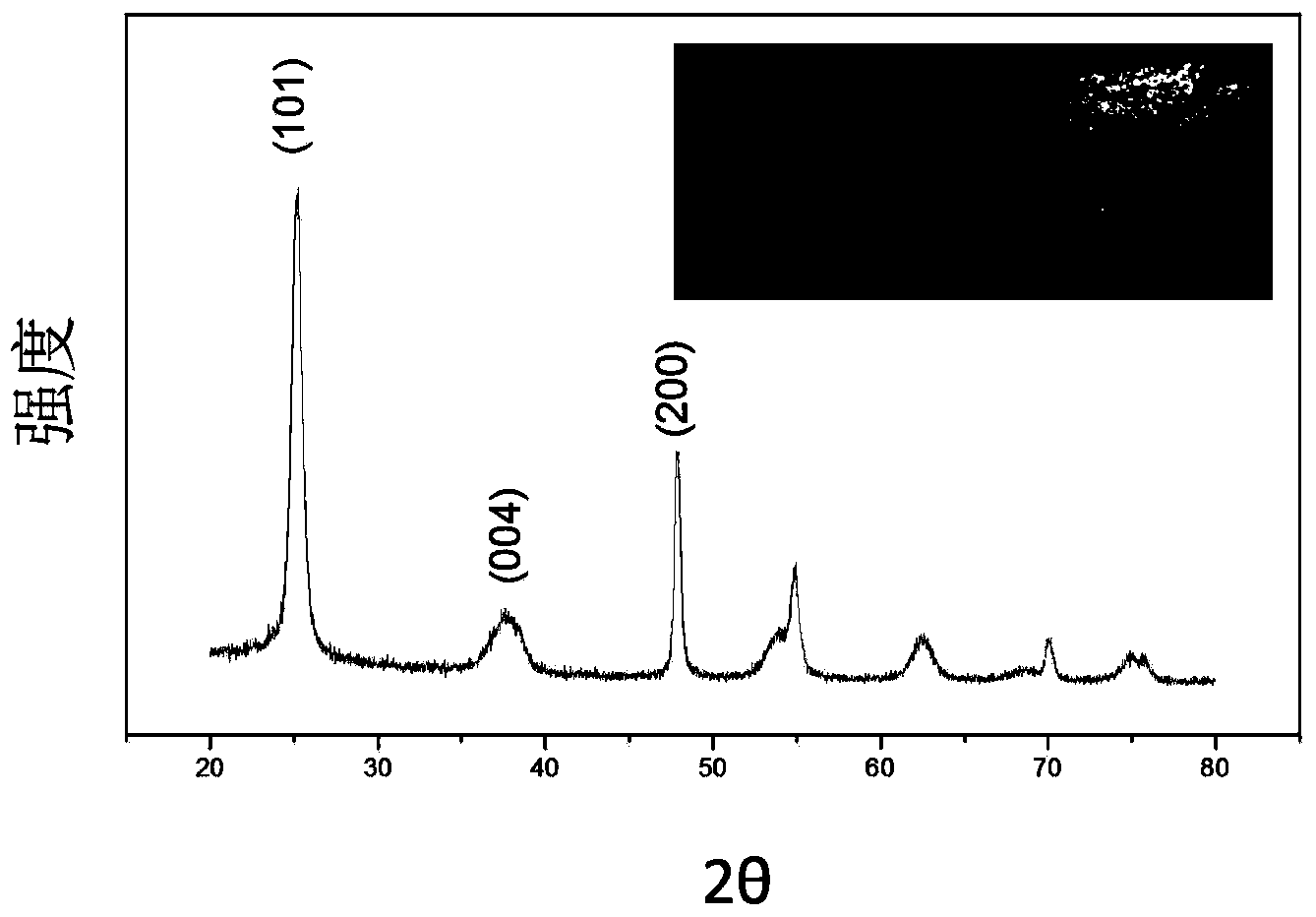

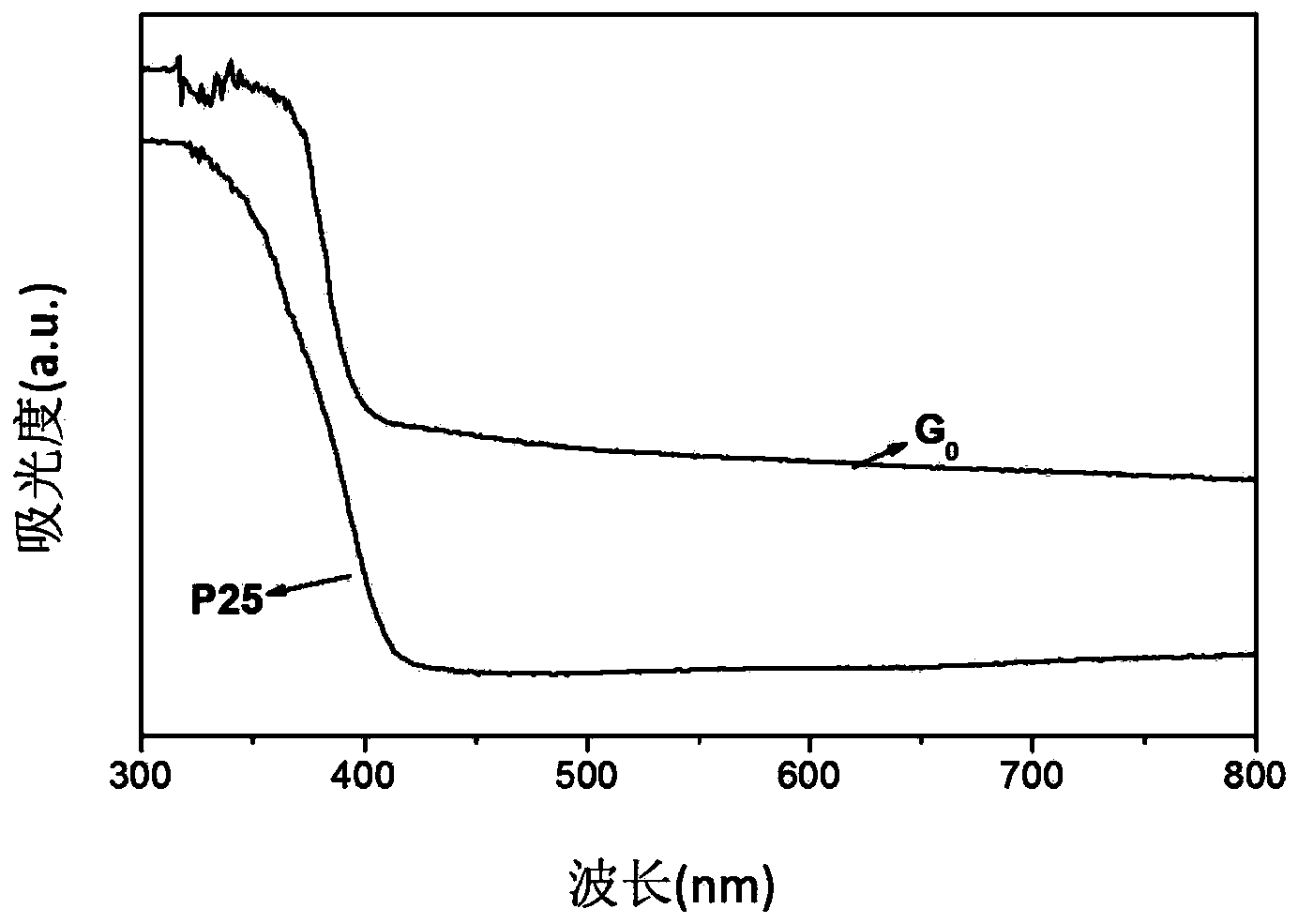

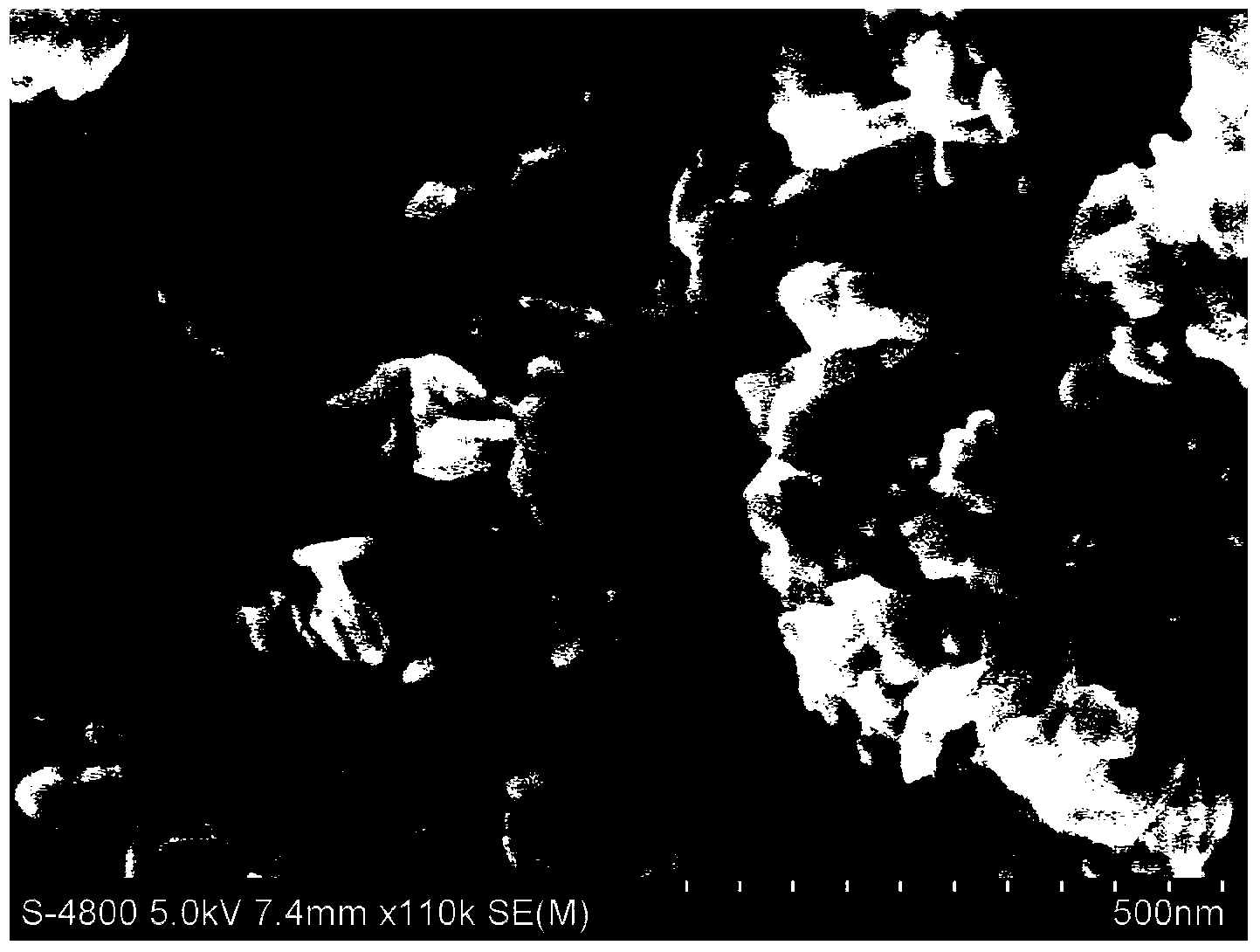

[0022] Sample G 0 Preparation process: Add 40ml of ethanol to a beaker, then add 10ml of tetrabutyl titanate, and stir evenly. Then 1.0ml of hydrofluoric acid (40%) was added dropwise, stirred evenly, moved to an autoclave, and reacted at 180°C for 25h. Cooling, washing, vacuum drying, and finally calcination at 300°C for 10 hours under a nitrogen atmosphere to obtain titanium dioxide nanomaterials (sample G 0 ), which is rendered in gray. From the XRD diffraction pattern of the sample (attached figure 1 ) It can be seen that the sample is anatase titanium dioxide with a grain size of 50nm. From the SEM image of the sample (attached image 3 ) can also be observed; from the UV-vis map of the sample (attached figure 2 ) It can be seen that the sample has a strong absorption for light with a wavelength of 400-800nm.

[0023] Sample G 0 Catalytic reaction: Add 30ml of 5mg / L methylene blue solution to the test tube, then add 20mg of sample, place in a photoreactor, stir for...

example 2

[0025] Sample G 1 Preparation process: Add 50ml of isopropanol to a beaker, then add 10ml of tetrabutyl titanate, and stir evenly. Then 3.0ml of concentrated sulfuric acid (70%) was added dropwise, stirred evenly, moved to an autoclave, and reacted at 180°C for 5h. Cooling, washing, vacuum drying, and finally roasting at 500°C for 10 hours under a nitrogen atmosphere to obtain titanium dioxide nanomaterials (sample G 1 ), the color is gray, the sample is anatase titanium dioxide, and the grain size is 50nm.

[0026] Sample G 1 Catalytic reaction: Add 30ml of 5mg / L methylene blue solution to the test tube, then add 20mg of sample, place in photoreactor, stir for 1h to reach adsorption equilibrium. Turn on the xenon lamp, react for 3 hours, and take a sample every hour. The concentration of methylene blue was analyzed by a UV-visible spectrophotometer. The degradation rate of methylene blue in this sample was 96% under visible light, which was better than 75% of commercial P...

example 3

[0028] Sample G 2 Preparation process: Add 20ml of butanol to a beaker, then add 10ml of titanium isopropoxide, and stir evenly. Then 4.0ml of concentrated sulfuric acid (70%) was added dropwise, stirred evenly, moved to an autoclave, and reacted at 180°C for 15h. Cooling, washing, vacuum drying, and finally baking at 700 °C for 10 hours under an argon atmosphere to obtain titanium dioxide nanomaterials (sample G 2 ), whose color is gray, from the XRD diffraction pattern of the sample (attached Figure 5 ) It can be seen that the sample is anatase titanium dioxide with a grain size of 60nm.

[0029] Sample G 2 Catalytic reaction: Add 30ml of 5mg / L methylene blue solution to the test tube, then add 20mg of sample, place in photoreactor, stir for 1h to reach adsorption equilibrium. Turn on the xenon lamp, react for 3 hours, and take a sample every hour. The concentration of methylene blue was analyzed by a UV-visible spectrophotometer. The degradation rate of methylene blue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com