Killed non-tempered steel containing sulfur and aluminum and morphology control method of sulfides thereof

A non-quenched and tempered steel and control method technology, applied in the field of metallurgy, can solve the problems of reducing the quality of the cast slab, easy to accumulate current, disappear, etc., and achieve the effects of good fatigue resistance, improved fatigue resistance, and excellent cutting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with examples.

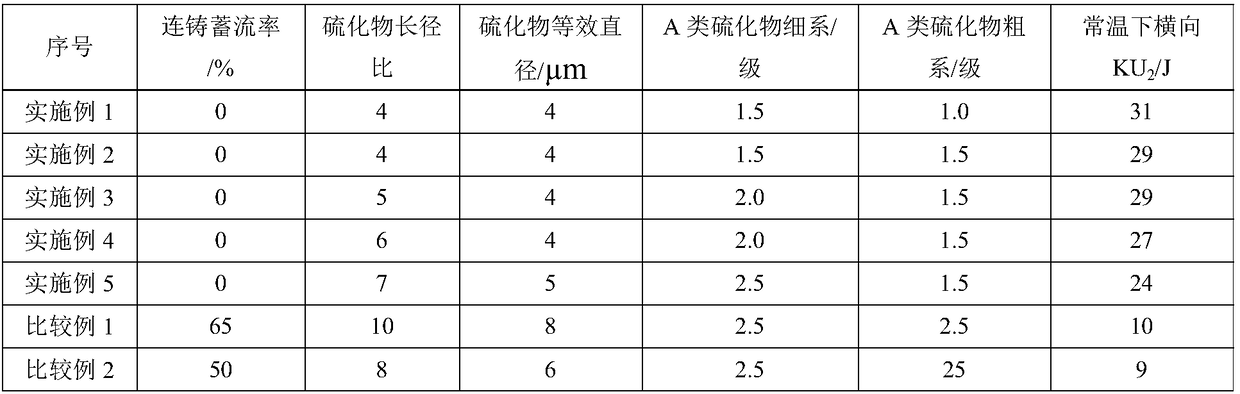

[0033] The chemical composition and weight percentage of the sulfur-containing aluminum-killed non-quenched and tempered steel in Examples 1-4 and Comparative Examples 1-3 are shown in Table 1.

[0034] Table 1 The chemical composition and weight percentage of the sulfur-containing aluminum-killed non-quenched and tempered steel of each embodiment and comparative example

[0035]

Example 1

Example 2

Example 3

Example 4

Example 5

Comparative example 1

Comparative example 2

C

0.32

0.38

0.44

0.47

0.50

0.38

0.41

Si

0.47

0.54

0.56

0.63

0.73

0.54

0.33

mn

1.20

1.45

1.48

1.50

1.59

1.45

1.20

V

0.13

0.17

0.26

0.27

0.30

0.17

0.23

Ti

0.02

0.032

0.042

0.045

0.048

0.032

0.05

Cr

0.16

0.28

0.40

0.44

0.47

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com