PtCu electric catalyst for fuel battery, preparation method and application thereof

An electrocatalyst, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of restricting the commercialization process of fuel cells, low reserves, high cost, and achieve excellent electrocatalytic methanol oxidation performance, large application and development. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 0.5 g of triblock copolymer P123 in 20 mL of double-distilled water by ultrasonic stirring; add 1 mL of chloroplatinic acid hexahydrate (0.8 g / mL), 3 mg of anhydrous copper chloride and 40 mg potassium iodide, stirred, ultrasonically dissolved, and mixed evenly.

[0032] (2) Transfer the mixed solution to the liner of a 50 mL polytetrafluoroethylene reactor, seal the reactor tightly, place it in a blast drying oven, and react at 180°C for 12 hours.

[0033] (3) Naturally cool to room temperature, centrifuge the black suspension obtained after the reaction at 10,000 r / min, wash twice with twice distilled water, then three times with absolute ethanol, and finally add the washed product to The PtCu electrocatalyst for fuel cells can be obtained by dispersing and protecting in absolute ethanol.

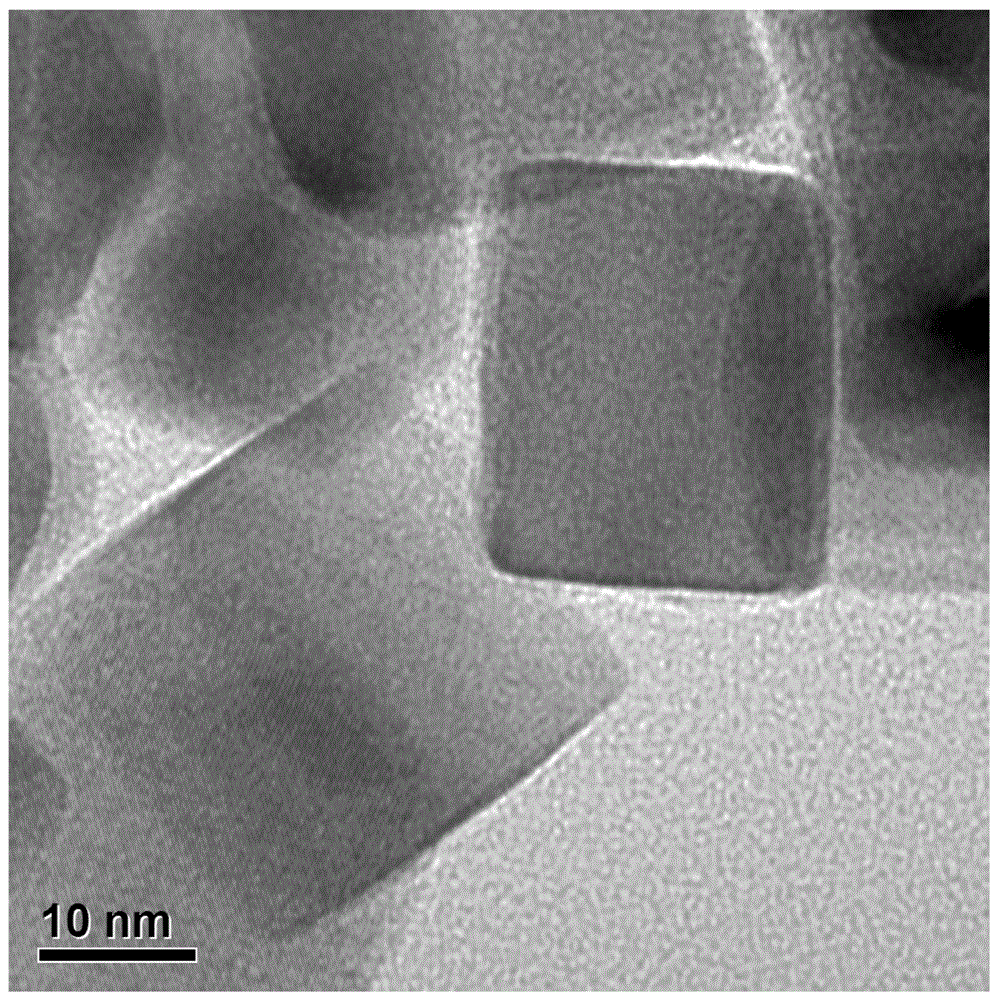

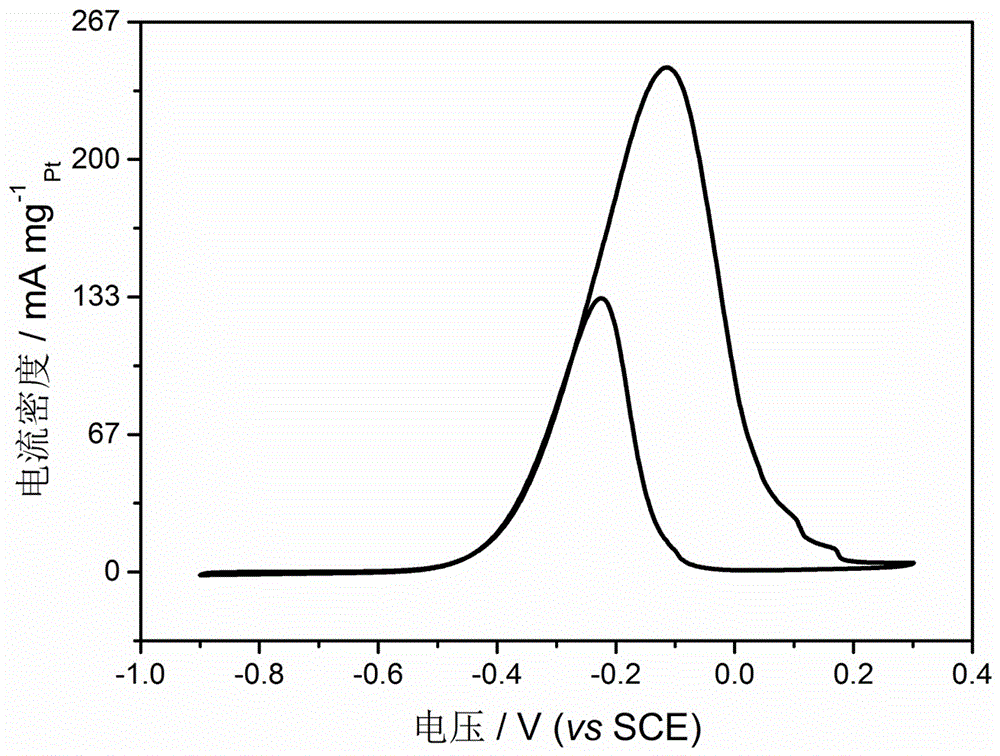

[0034] figure 1 Shown is the transmission electron microscope (TEM) figure of the PtCu electrocatalyst for the fuel cell prepared by the present embodiment, by fig...

Embodiment 2

[0038] (1) Dissolve 0.5 g of triblock copolymer P123 in 20 mL of double-distilled water by ultrasonic stirring; add 1 mL of chloroplatinic acid hexahydrate (0.8 g / mL), 3 mg of anhydrous copper chloride and 20 mg potassium iodide, stirred, ultrasonically dissolved, and mixed evenly.

[0039] (2) Transfer the mixed solution to the liner of a 50 mL polytetrafluoroethylene reactor, seal the reactor tightly, place it in a blast drying oven, and react at 180°C for 12 hours.

[0040] (3) Naturally cool to room temperature, centrifuge the black suspension obtained after the reaction at 10,000 r / min, wash twice with twice distilled water, then three times with absolute ethanol, and finally add the washed product to The PtCu electrocatalyst for fuel cells can be obtained by dispersing and protecting in absolute ethanol.

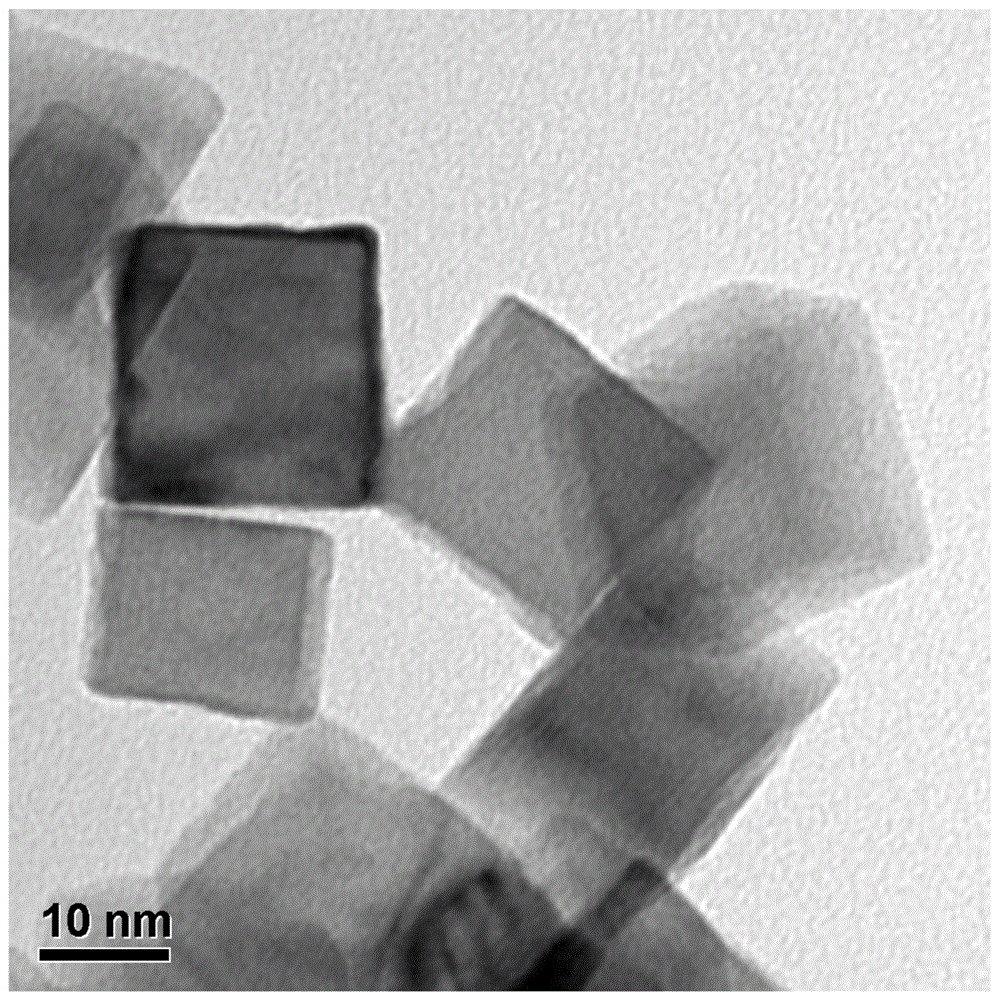

[0041] image 3 Shown is the TEM figure of the PtCu electrocatalyst for the fuel cell prepared by the present embodiment, by image 3 It can be seen that the prep...

Embodiment 3

[0045] (1) Dissolve 0.5 g of triblock copolymer P123 in 20 mL of double-distilled water by ultrasonic stirring; add 1 mL of chloroplatinic acid hexahydrate (0.8 g / mL), 3 mg of anhydrous copper chloride and 1 mg potassium iodide, stirred, ultrasonically dissolved, and mixed evenly.

[0046] (2) Transfer the mixed solution to the liner of a 50 mL polytetrafluoroethylene reactor, seal the reactor tightly, place it in a blast drying oven, and react at 180°C for 12 hours.

[0047] (3) Naturally cool to room temperature, centrifuge the black suspension obtained after the reaction at 10,000 r / min, wash twice with twice distilled water, then three times with absolute ethanol, and finally add the washed product to The PtCu electrocatalyst for fuel cells can be obtained by dispersing and protecting in absolute ethanol.

[0048] Figure 5 Shown is the TEM figure of the PtCu electrocatalyst for the fuel cell prepared by the present embodiment, by Figure 5 It can be seen that the as-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com