PtPd electrocatalyst used for fuel cell and preparation method for PtPd electrocatalyst

An electrocatalyst, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of restricting the commercialization process of fuel cells, high cost, low reserves, etc., and achieve excellent electrocatalytic methanol oxidation performance and short synthesis time. , the effect of large applications and development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Take 1.0 g of triblock copolymer P123 and dissolve it in 30 mL of double-distilled water by ultrasonic stirring, transfer it to a three-necked bottle and stir it on a magnetic stirrer with a temperature controller, and control the temperature at 30 ℃.

[0030] (2) Slowly add 10 mL of K to the P123 solution dropwise 2 PdCl 4 solution (0.02mmol / L), after the dropwise addition was completed, immediately continue to add 10 mL of K 2 PtCl 6 Solution (0.02mmol / L), magnetic stirring reaction 2h.

[0031] (3) Naturally cool to room temperature, centrifuge the black suspension obtained after the reaction at 10,000 r / min, wash twice with twice distilled water, then wash three times with absolute ethanol, and finally wash the The product is added into absolute ethanol for dispersion protection to obtain a PtPd-1 electrocatalyst for fuel cells.

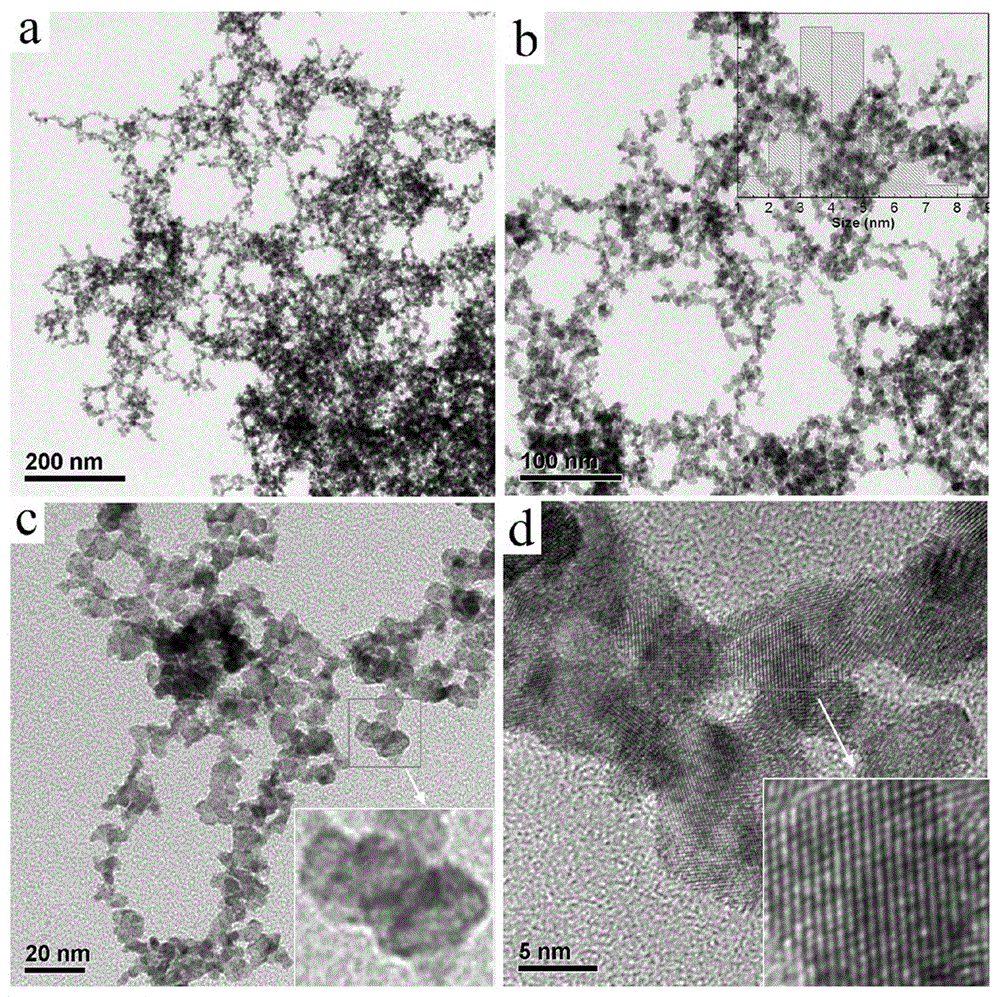

[0032] figure 1 Shown is the transmission electron microscope (TEM) figure of the PtPd-1 electrocatalyst for fuel cell prepar...

Embodiment 2

[0036] (1) Take 1.0 g of triblock copolymer P123 and dissolve it in 30 mL of double-distilled water by ultrasonic stirring, transfer it to a three-necked bottle and stir it on a magnetic stirrer with a temperature controller, and control the temperature at 30 ℃.

[0037] (2) Slowly add 10 mL of K to the P123 solution dropwise 2 PdCl 4 (0.02mmol / L) and 10 mL K 2 PtCl 6 Solution (0.02mmol / L) mixed solution, magnetic stirring reaction 2h.

[0038] (3) Naturally cool to room temperature, centrifuge the black suspension obtained after the reaction at 10,000 r / min, wash twice with twice distilled water, then wash three times with absolute ethanol, and finally wash the The product is added into anhydrous ethanol for dispersion protection to obtain a PtPd-2 electrocatalyst for fuel cells.

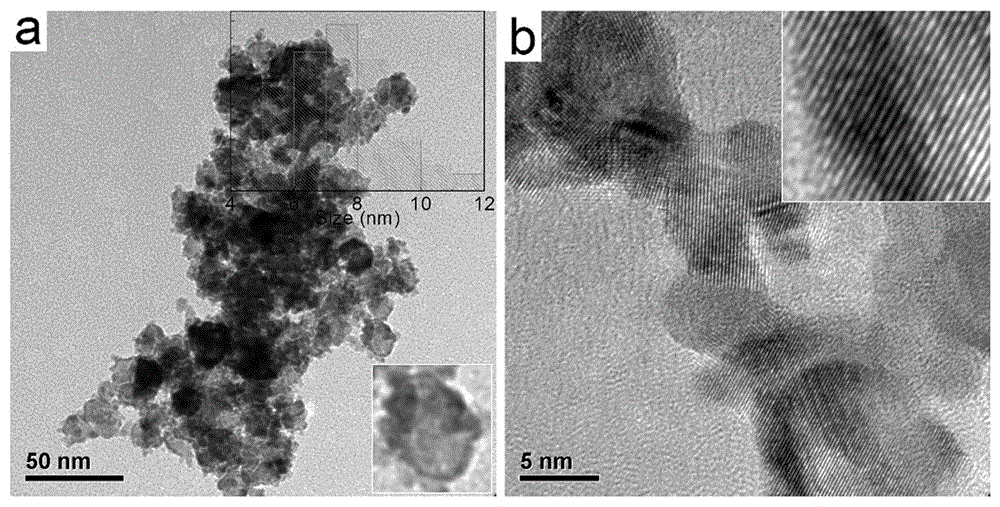

[0039] figure 2 Shown is the transmission electron microscope (TEM) figure of the PtPd-2 electrocatalyst for the fuel cell prepared by the present embodiment, by figure 2 a It can be se...

Embodiment 3

[0043] (1) Dissolve 1.0 g of triblock copolymer P123 in 30 mL of secondary distilled water with stirring and ultrasonic, transfer it to a three-necked flask and place it on a magnetic stirrer with a temperature controller to stir, and control the temperature at 100 °C.

[0044] (2) Add 10 mL K slowly dropwise to the P123 solution 2 PdCl 4 (0.02mmol / L) and 10 mL K 2 PtCl 6 The mixed solution of the solution (0.02mmol / L) was reacted with magnetic stirring for 2h.

[0045] (3) Cool to room temperature naturally, centrifuge the black suspension obtained after the reaction at 10,000 r / min, first wash twice with double distilled water, then three times with absolute ethanol, and finally wash the cleaned The product is added with anhydrous ethanol to disperse and protect to obtain PtPd-100 electrocatalyst for fuel cell.

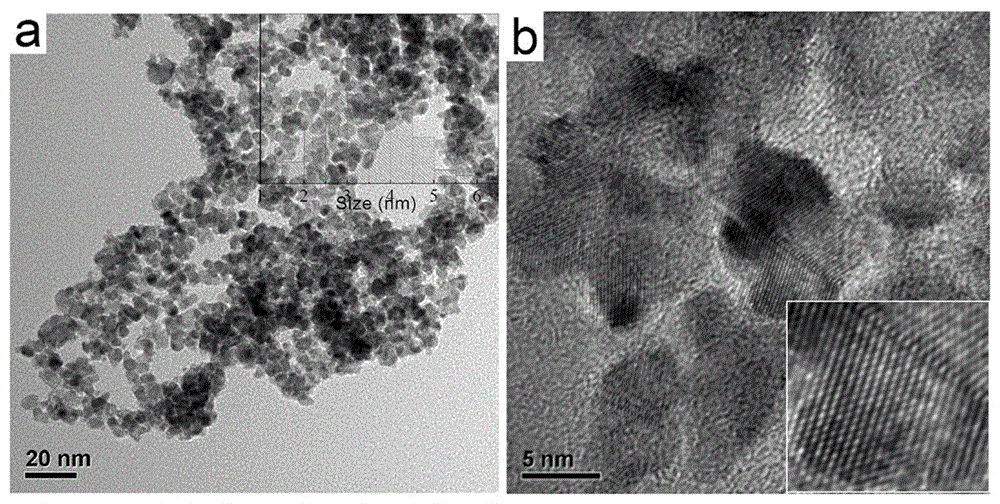

[0046] image 3 Shown is the transmission electron microscope (TEM) image of the PtPd-100 electrocatalyst for fuel cells prepared in this example, from im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com