Preparation method for blue sheet-like titanium dioxide nanomaterial

A titanium dioxide and nanomaterial technology, applied in the field of nanomaterials and photocatalysis, can solve the problems of low utilization rate and difficult absorption of visible light, and achieve the effects of low equipment requirements, simple operation, and improved absorption and utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

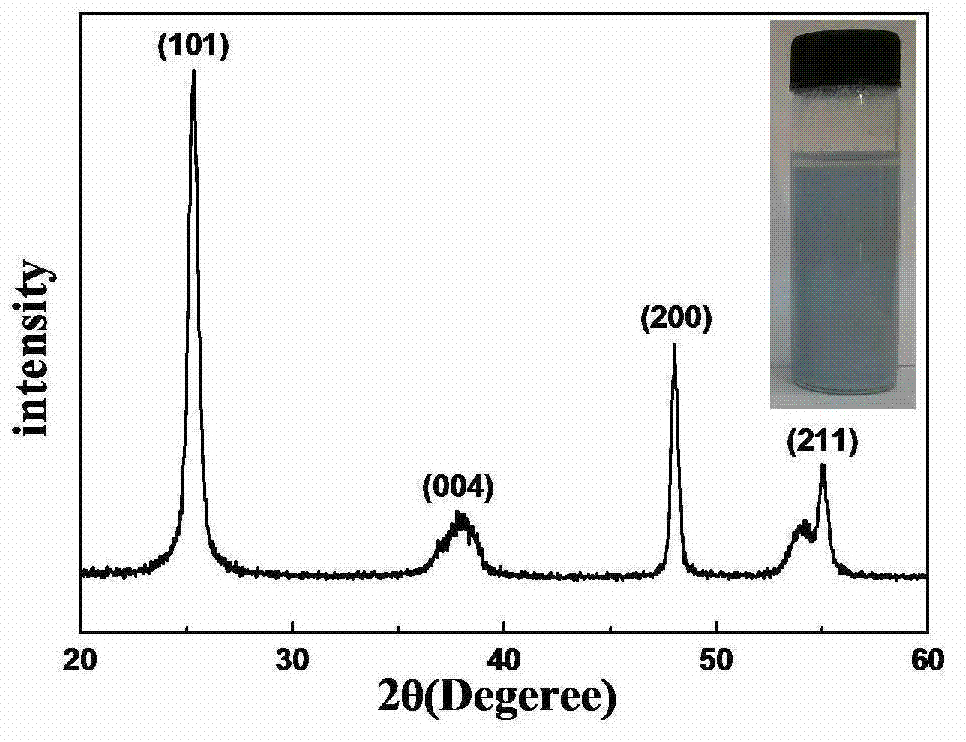

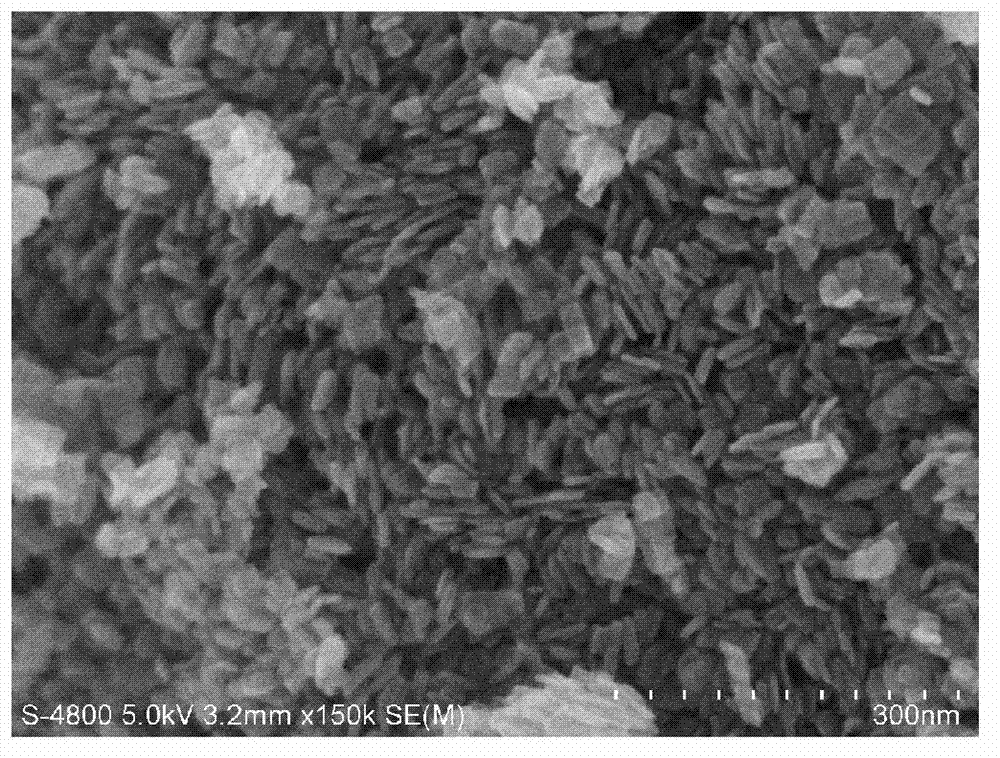

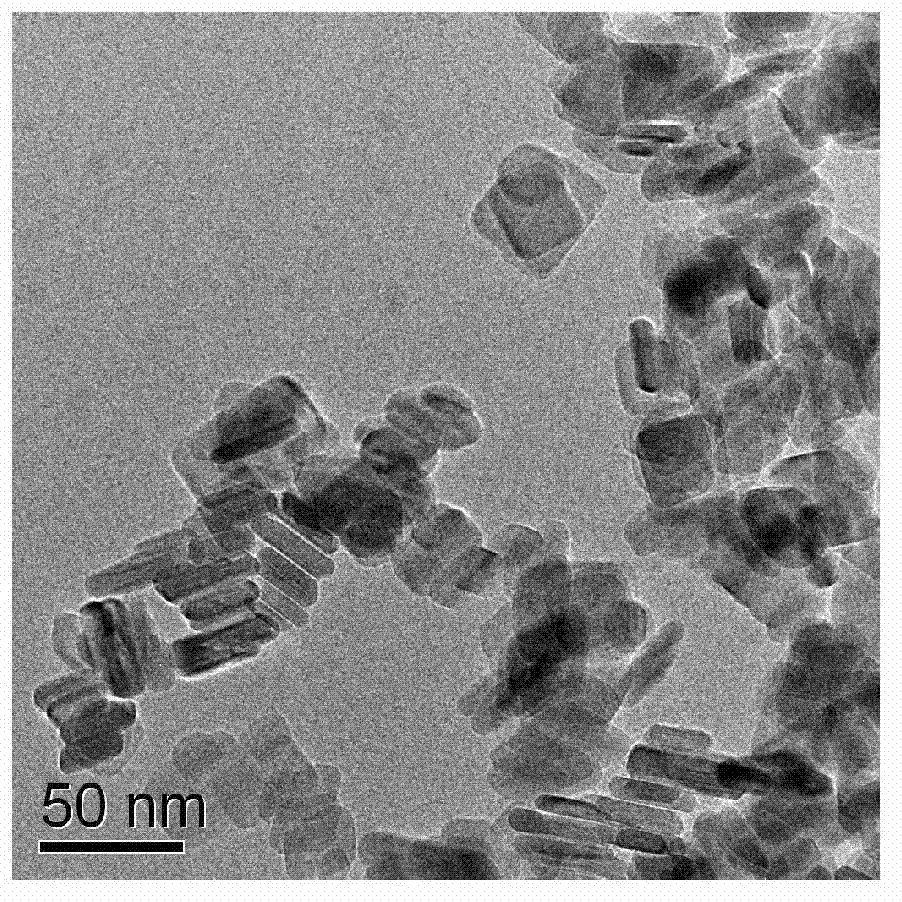

[0021] Sample T 0 Preparation: Add 100ml of butanol and 20ml of tetrabutyl titanate into a plastic beaker, stir well to obtain solution A. Then, 1.0ml of 50% hydrofluoric acid was added dropwise to solution A, and stirred to obtain clear solution B. Solution B was moved to the reactor, and reacted at 180° C. for 30 h. Cool naturally (blue precipitate), wash with ethanol and centrifuge 3 times, dry, and finally get the blue flaky anatase titanium dioxide sample T 0 . Dissolve the sample in ethanol, and the photo of its dispersion in ethanol is shown in figure 1 As shown in the upper right inset, it is blue; it can be seen that the sample T 0 Anatase titanium dioxide (see figure 1 ), the grain size is 16nm, and the morphology is flake (see Figure 2-3 ), can absorb visible light from 400nm to 700nm (see Figure 4 ). The sample T 0 The degradation rate of methylene blue under visible light is 95.1%, which is better than commercial P25 (75.3%) (see Figure 5 ).

example 2

[0023] Sample T 1 Preparation: Add 80ml of propanol and 20ml of isopropyl titanate into a plastic beaker, stir well to obtain solution A. Then, 3.6ml of 40% hydrofluoric acid was added dropwise to solution A, and stirred to obtain clear solution B. Solution B was moved to the reactor, and reacted for 12h at 100°C. Cool naturally (blue precipitate), wash with ethanol and centrifuge 3 times, dry, and finally get the blue flaky anatase titanium dioxide sample T 1 . Dissolve the sample in ethanol, and the photo of its dispersion in ethanol is shown in Figure 6 As shown in the upper right inset, it is blue; known sample T 1 Anatase titanium dioxide (see Figure 6 ), the grain size is 14nm, and the morphology is flake (see Figure 7 ), can absorb visible light from 400nm to 700nm. The sample T 1 The degradation rate of methylene blue under visible light is 96.7%, which is better than commercial P25 (74.6%).

example 3

[0025] Sample T 2 Preparation: Add 50ml of ethanol and 20ml of tetrabutyl titanate into a plastic beaker, stir well to obtain solution A. Then, 5.0ml of 30% hydrofluoric acid was added dropwise to solution A, and stirred to obtain clear solution B. Solution B was moved to the reactor, and reacted for 60h at 200°C. Cool naturally (blue precipitate), wash with ethanol and centrifuge 3 times, dry, and finally get the blue flaky anatase titanium dioxide sample T 2 . Dissolve the sample in ethanol, and the photo of its dispersion in ethanol is shown in Figure 8 As shown in the upper right inset, it is blue; it can be seen that the sample T 2 Anatase titanium dioxide (see Figure 8 ), the grain size is 28nm, and the morphology is flake (see Figure 9 ), can absorb visible light from 400nm to 700nm. The sample T 2 The degradation rate of methylene blue under visible light is 96.2%, which is better than commercial P25 (74.7%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com