Plasma etching device

An etching device and plasma technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of poor control of the profile shape of deep trenches, affecting plasma density, etc., so as to improve process efficiency and product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

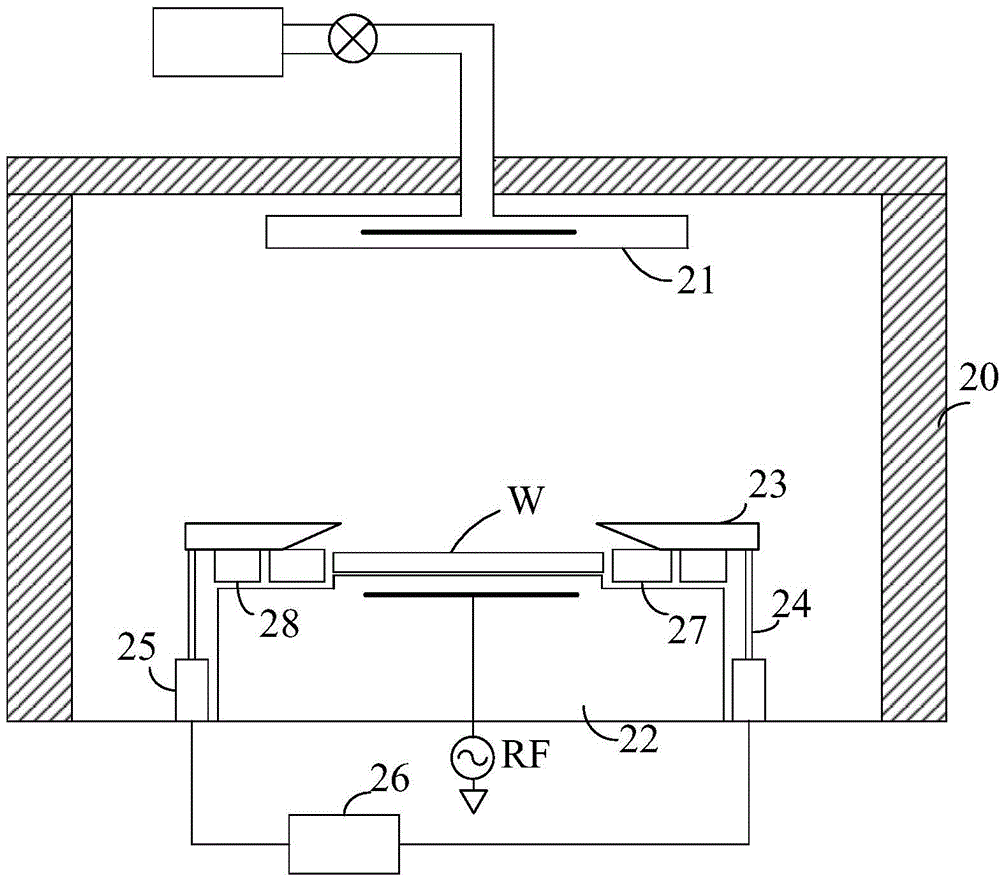

[0030] See Figure 2a and Figure 2b , which is a schematic structural diagram of the plasma etching device in this embodiment. The plasma etching device includes a reaction chamber 20, the top of the reaction chamber 20 is provided with a reaction gas shower head 21, the reaction gas shower head 21 includes an upper electrode, and the bottom of the reaction chamber 20 is provided with a The electrostatic chuck 22 of W, the lower electrode opposite to the upper electrode is arranged in the electrostatic chuck 22 . A radio frequency source RF is applied to the lower electrode to form a radio frequency electric field to ionize the etching gas to generate plasma. A liftable annular shielding member 23 is provided on the outer peripheral side of the substrate. As shown in the figure, the annular shielding member 23 is positioned above the surface of the substrate W in a non-contact manner by the support rod 24 . Preferably, three support rods 24 are evenly distributed along th...

Embodiment 2

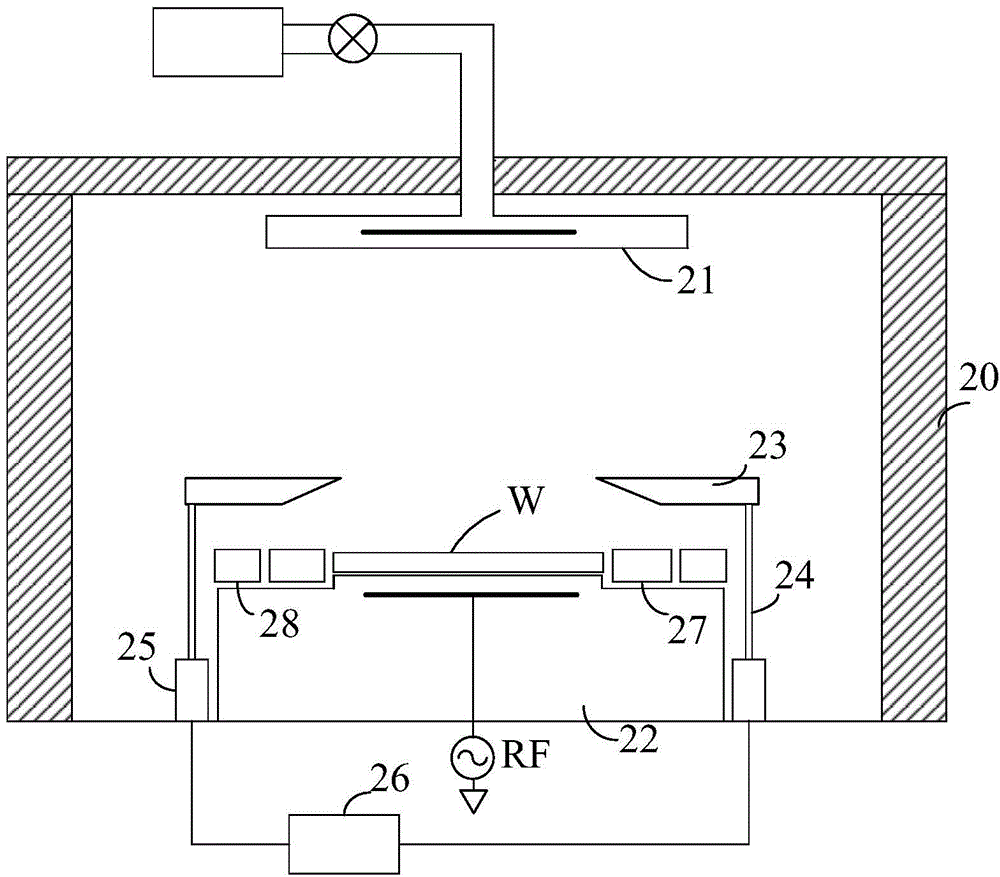

[0034] image 3 It is a structural schematic diagram of another embodiment of the plasma etching device provided by the present invention, which is characterized in that the movable annular shielding member 23 is a gas guide ring. The gas guide ring 23 is disposed above the surface of the substrate W through the support rod 24 in a non-contact manner. Preferably, three support rods 24 are evenly distributed along the circumference of the gas guiding ring 23 , one end of which is fixedly connected to the gas guiding ring 23 , and the other end is connected to the driving unit 25 . The drive unit 25 receives a signal from the control unit 26 to drive the support rod to drive the gas guide ring 23 to move in the vertical direction. Other components in the plasma etching device, such as the electrostatic chuck 22 , the gas shower head 21 , the control unit 26 and the drive unit 25 , can be configured with reference to the foregoing embodiments.

[0035] The gas guide ring 23 its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com