Thermal desorption heating device for oily soil restoration

A technology for heating equipment and soil remediation, applied in the restoration of polluted soil, etc., can solve the problems of poor remediation effect of oily soil, low desorption efficiency, easy generation of flash points, etc., so as to avoid sudden burst damage to equipment and improve the restoration effect. , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] (1) Since the oily soil is placed in the lower part of the casing 2 (whether it is figure 1 inside the heating tank 7, or figure 2 On the conveyor belt 61 in the middle, the oily soil is all in the lower part in the housing 2, even if the heating tank 7 rotates, most of the oily soil is also in the lower part in the housing 2 under the action of gravity), and the microwave heating device 3 and ultrasonic dispersion Device 4 all penetrates casing 2 (and figure 1 The heating tank 7) in the oily soil directly acts on the oily soil, so the microwave heating device 3 and the ultrasonic dispersing device 4 are fixed on the top of the housing 2, so that the oily soil can be maintained between the microwave heating device 3 and the ultrasonic dispersing device 4. A certain distance, which not only helps the microwave heating device 3 directly heat the inside of the oily soil to make the heating more uniform, but also helps the ultrasonic dispersing device 4 to disperse the co...

Embodiment 1

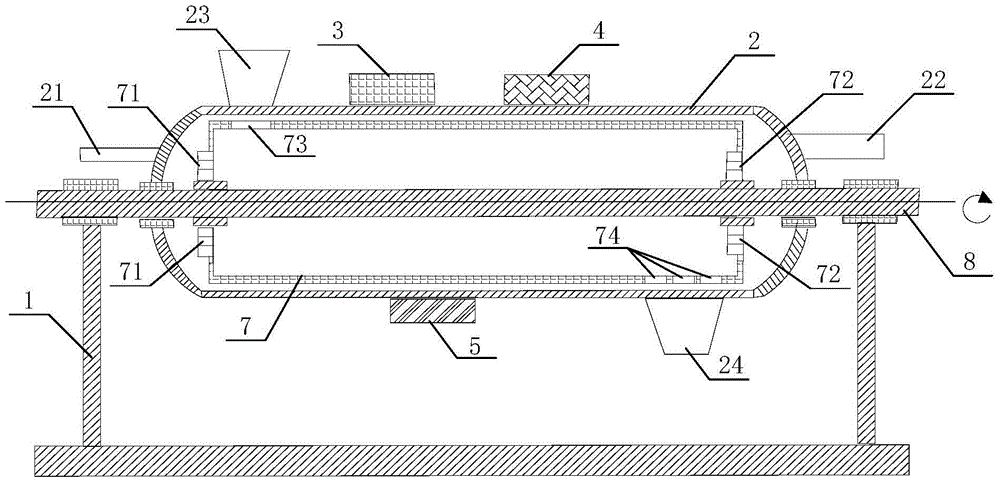

[0037] Such as figure 1 As shown, a heat desorption and heat addition equipment for oily soil remediation, its specific structure may include: a bracket 1, a shell 2, a microwave heating device 3, an ultrasonic dispersion device 4, an infrared heating device 5, a heating tank 7, a tank Body shaft 8, control device and temperature detection device;

[0038] The housing 2 is fixed on the bracket 1; the left end surface of the housing 2 is provided with a housing air inlet 21, and the right end surface of the housing 2 is provided with a housing air outlet 22; the top of the left end of the housing 2 is provided with a housing The body feed port 23, and the bottom of the right end of the housing 2 is provided with a housing discharge port 24; the microwave heating device 3 and the ultrasonic dispersion device 4 are fixed on the top of the housing 2; the infrared heating device 5 is fixed on the bottom of the housing 2 Bottom; the control device is electrically connected with the...

Embodiment 2

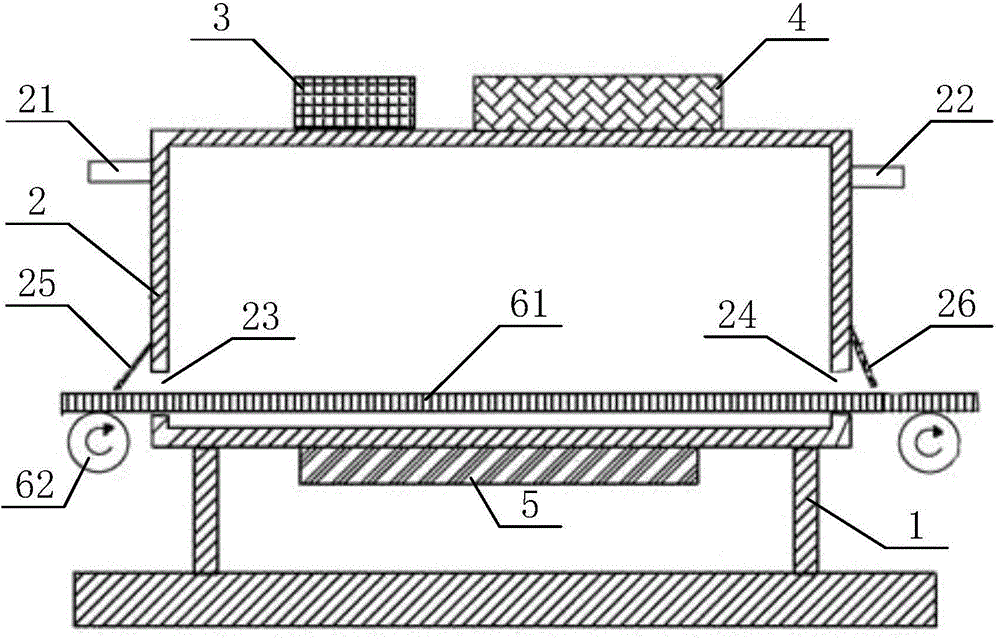

[0044] Such as figure 2 As shown, a heat desorption and heat addition equipment for oily soil remediation, its specific structure may include: bracket 1, shell 2, microwave heating device 3, ultrasonic dispersion device 4, infrared heating device, belt transmission mechanism, control device and temperature detection device;

[0045] The housing 2 is fixed on the bracket 1; the left end surface of the housing 2 is provided with a housing air inlet 21 and a housing feed inlet 23, while the right end surface of the housing 2 is provided with a housing air outlet 22 and a housing The discharge port 24; the shell feed port 23 and the shell discharge port 24 are located below the horizontal axis of the shell 2; the microwave heating device 3 and the ultrasonic dispersion device 4 are fixed on the top of the shell 2; the infrared heating device 5 It is fixed on the bottom of the casing 2; the control device is electrically connected with the microwave heating device 3, the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com