Solvothermal method used for preparing LiFePO4

A solvothermal method and solution technology, applied in the field of solvothermal preparation of LiFePO4, can solve the problems of unsuitable high-rate discharge and large particle size, and achieve the effect of improving processing performance and compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

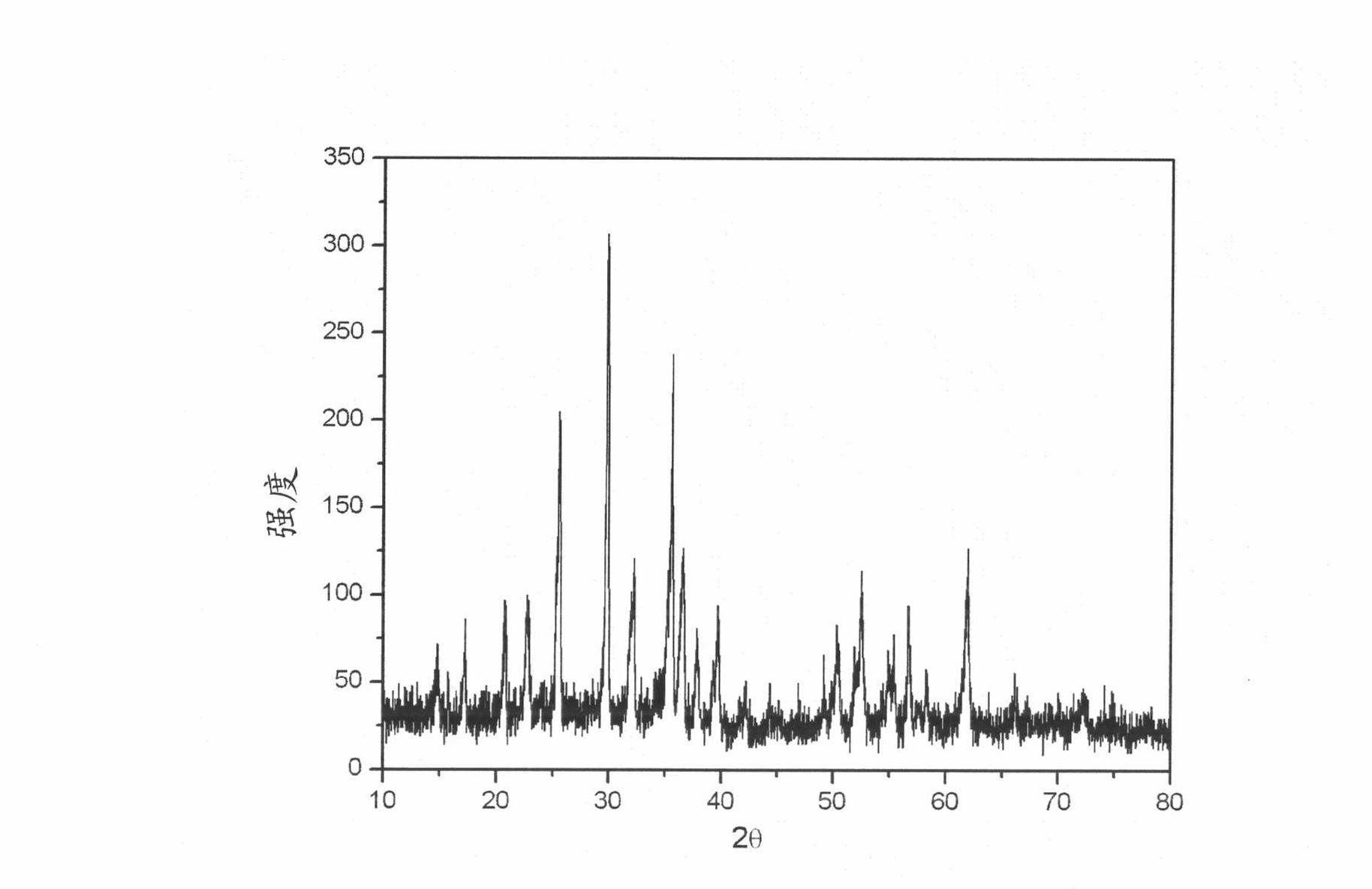

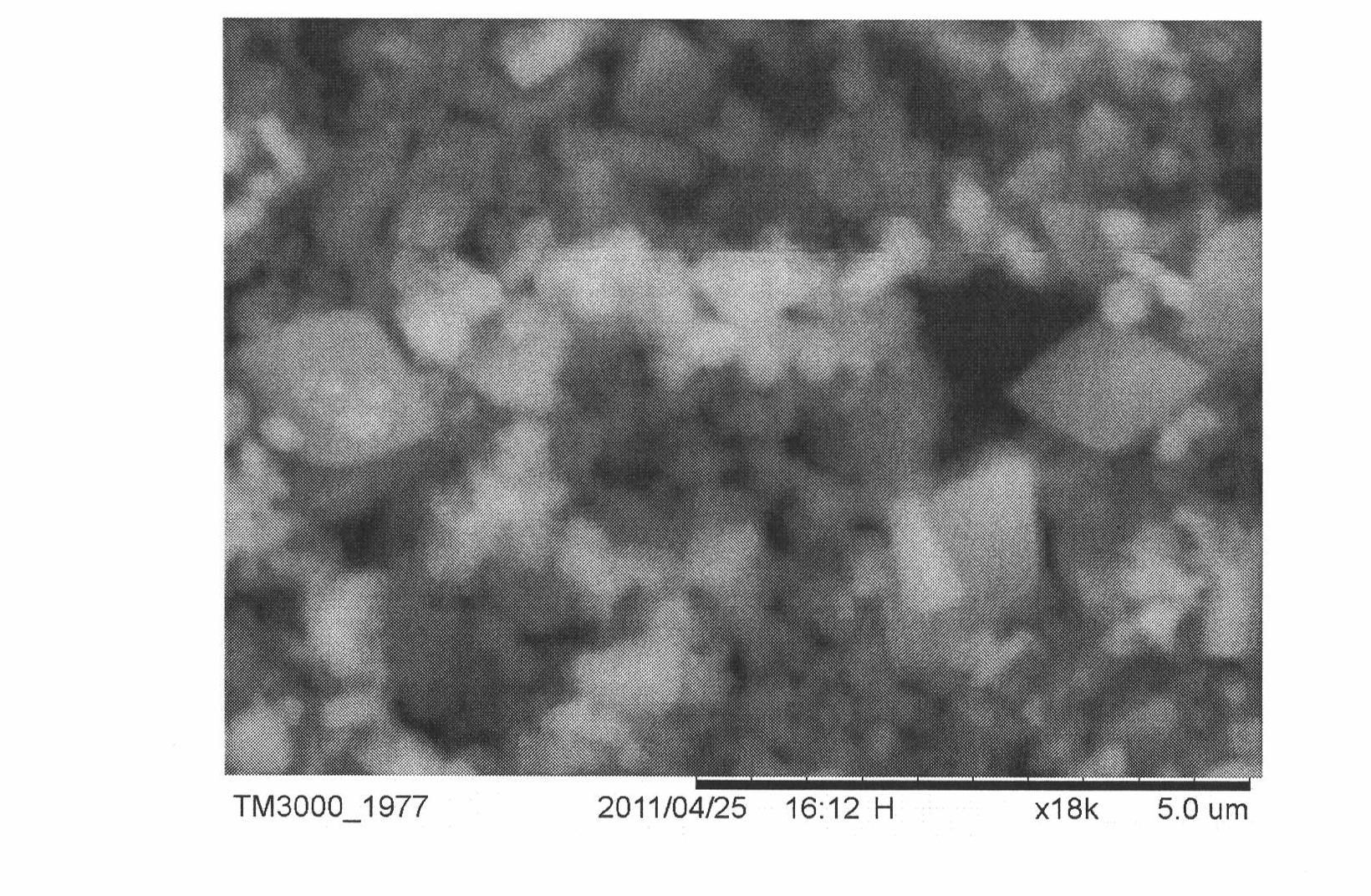

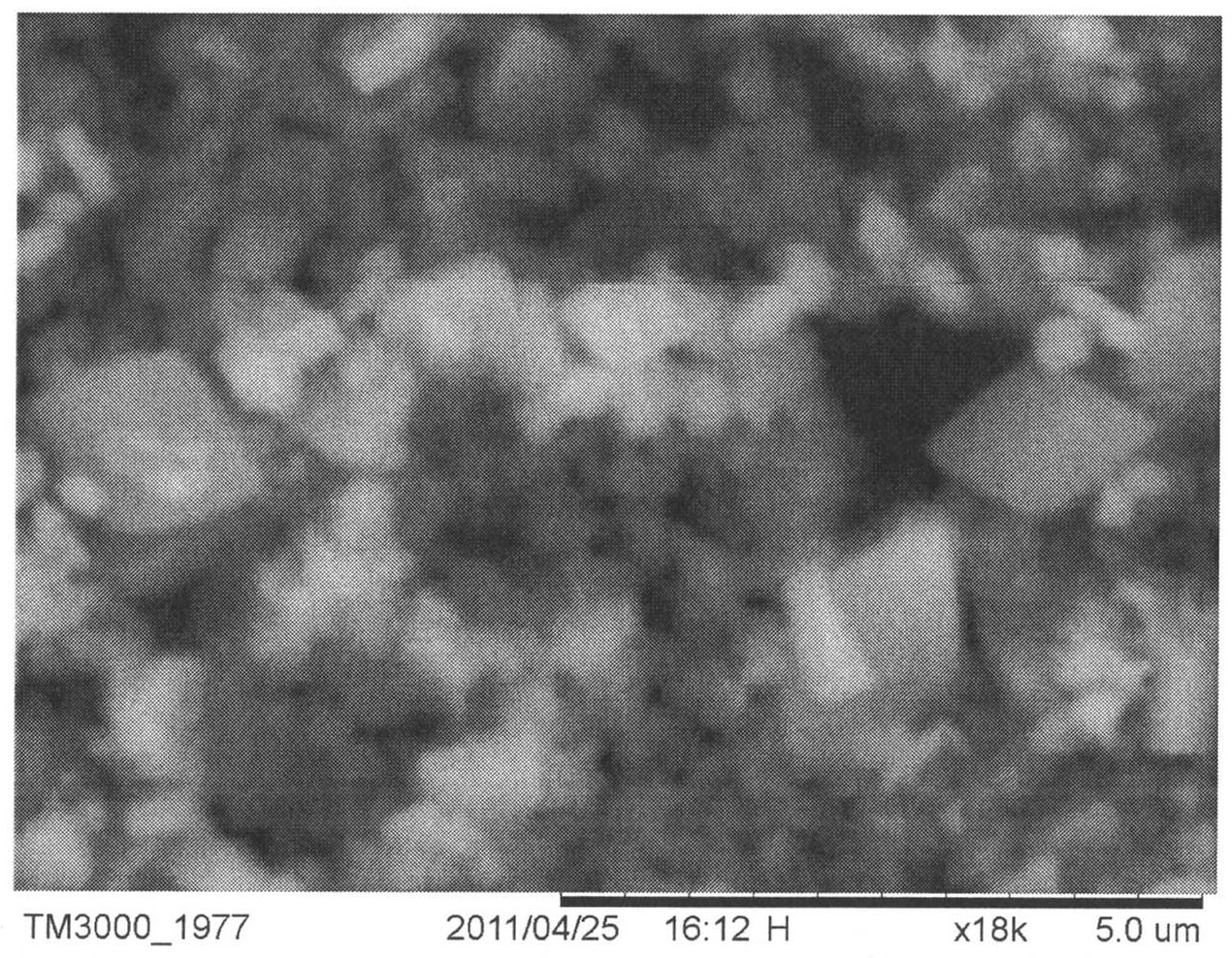

[0027] The stoichiometric ratio of phosphoric acid and ferrous sulfate was dissolved in deionized water to prepare 0.1 mol / L clear solution A. Then prepare 0.3mol / L lithium hydroxide solution and add 0.05mol / L reducing agent N 2 H 4 , and stir to form a clear and homogeneous solution B. While vigorously stirring A, slowly add solution B to A, stir evenly to obtain a dark green suspension, and use deionized water to centrifuge and wash the obtained product three times to obtain amorphous LiFePO 4 precipitation. The obtained amorphous LiFePO 4Disperse in an appropriate amount of ethylene glycol, disperse uniformly by ultrasonic, then transfer to a hydrothermal reactor, and react at 200 ° C for 10 hours under constant stirring, and use deionized water, anhydrous alcohol, etc. for the obtained product. The product was washed several times and dried at 80°C under certain vacuum conditions to obtain LiFePO with good crystallization and a particle size of 5 μm. 4 ,like figure 1...

Embodiment 2

[0029] Dissolve ammonium monohydrogen phosphate and ferrous sulfate in the stoichiometric ratio in deionized water, adjust with dilute sulfuric acid to make it clear, and prepare a clear solution A of 0.05mol / L. Then prepare 0.05mol / L lithium sulfate solution and add 0.01mol / L reducing agent N 2 H 4 , and stir to form a clear and homogeneous solution B. While vigorously stirring A, slowly add solution B to A, stir evenly to obtain a dark green suspension, centrifuge and wash the obtained product three times with deionized water to obtain amorphous LiFePO 4 . The obtained amorphous LiFePO 4 Disperse in an appropriate volume ratio of 1:1 ethylene glycol / CCl 4 In the mixed solvent, ultrasonically dispersed uniformly, then transferred to a hydrothermal reactor, and reacted at 180 ° C for 20 hours under constant stirring, and the obtained product was washed several times with deionized water, anhydrous alcohol, etc. Dry at 80°C under vacuum to obtain nano-LiFePO4 with good cry...

Embodiment 3

[0031] Dissolve phosphoric acid and ferrous ammonium sulfate in the stoichiometric ratio in deionized water to prepare a 0.5mol / L clear solution A, then prepare a 0.3mol / L lithium hydroxide solution and add a reducing agent to a concentration of 0.05mol / L Reducing agent vitamin C, stir evenly to form a clear and homogeneous solution B. While vigorously stirring, solution B was slowly added to A, and stirred evenly to obtain a dark green suspension. The obtained product was centrifuged and washed three times with deionized water. The obtained amorphous LiFePO4 was dispersed in an appropriate amount of triethylene glycol / cyclohexane organic mixed solvent with a volume ratio of 1:1, and 2% by volume of the morphology regulator succinic acid was added, and a 1% by mass ratio of surface The active agent sodium lauryl sulfate was dispersed uniformly by ultrasonic, and then transferred to a hydrothermal reactor, and reacted at 240 ° C for 20 hours under constant stirring, and the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com