Centrifugal casting coating for cylinder liners and preparation method thereof

A centrifugal casting and cylinder liner technology, which is applied in casting molding equipment, coatings, casting molds, etc., can solve the problems of unfavorable cylinder liner blank conformal casting, unfavorable metallographic structure, thick coating thickness, etc., and achieve heat insulation performance Excellent, good metallographic structure, and the effect of reducing machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Get the following raw material parts by weight:

[0031] Silica powder: 100

[0033] High alumina bauxite: 22

[0034] Sodium alkylbenzene sulfonate: 0.7

[0035] Water: 150,

[0036] Among them: the silica powder particle size of 150-180 mesh accounts for 30%, the particle size of 200-250 mesh accounts for 45%, and the particle size of 250-300 mesh accounts for 25%. The particle size of sodium bentonite and high alumina bauxite are both 200-350 mesh.

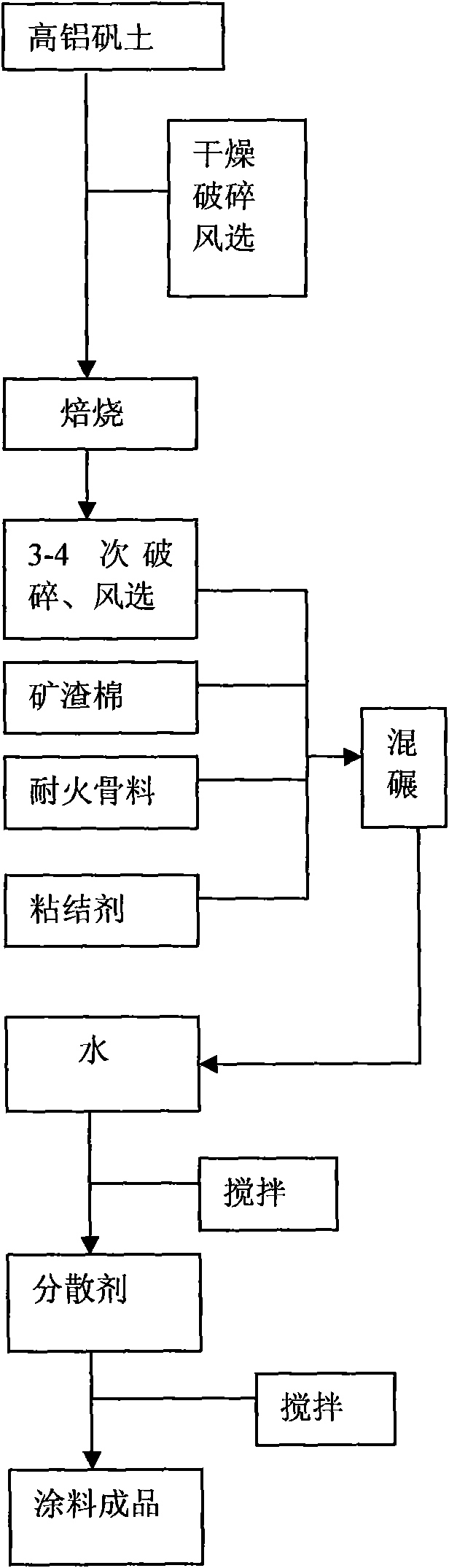

[0037] First dry the above-mentioned high-alumina bauxite at a temperature of 105±10°C, then pulverize it, and then carry out winnowing to remove impurities, then put it into a rotary kiln for roasting, the highest temperature for roasting is 1100°C, and then pulverize after roasting. Then carry out 3 to 4 air separation and classification to obtain high alumina bauxite powder with a particle size of 200-350 mesh.

[0038] Take 22 parts by weight of the prepared high-alumina bauxite as...

Embodiment 2

[0046] Get the following raw material parts by weight:

[0047] Silica powder: 100

[0048] Sodium bentonite: 16

[0049] High alumina bauxite: 25

[0050] Sodium stearate: 0.8

[0051] Water: 170,

[0052] Among them: the silica powder particle size of 150-180 mesh accounts for 30%, the particle size of 200-250 mesh accounts for 45%, and the particle size of 250-300 mesh accounts for 25%. The particle size of sodium bentonite and high alumina bauxite are both 200-350 mesh.

[0053] First dry the above-mentioned high-alumina bauxite at a temperature of 105±10°C, then pulverize it, and then carry out winnowing to remove impurities, then put it into a rotary kiln for roasting, the highest temperature for roasting is 1100°C, and then pulverize after roasting. Then carry out 3 to 4 air separation and classification to obtain high alumina bauxite powder with a particle size of 200-350 mesh.

[0054] Take 25 parts by weight of the prepared high-alumina bauxite as an insulating...

Embodiment 3

[0057] Get the following raw material parts by weight:

[0058] Silica powder: 100

[0059] Sodium bentonite: 20

[0060] High alumina bauxite: 30

[0061] Sodium stearate: 1.15

[0062] Water: 200,

[0063] Among them: the silica powder particle size of 150-180 mesh accounts for 30%, the particle size of 200-250 mesh accounts for 45%, and the particle size of 250-300 mesh accounts for 25%. The particle size of sodium bentonite and high alumina bauxite are both 200-350 mesh.

[0064] First dry the above-mentioned high-alumina bauxite at a temperature of 105±10°C, then pulverize it, and then carry out winnowing to remove impurities, then put it into a rotary kiln for roasting, the highest temperature for roasting is 1100°C, and then pulverize after roasting. Then carry out 3 to 4 air separation and classification to obtain high alumina bauxite powder with a particle size of 200-350 mesh.

[0065] Take 30 parts by weight of the prepared high-alumina bauxite as an insulatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com