High temperature resistant self-lubricating bearing material and preparation method thereof

A self-lubricating bearing and high temperature resistant technology, applied in the field of lubricating materials, can solve the problems of insufficient high temperature wear resistance, low friction coefficient wear resistance and other problems, and achieve the effects of easy parameter control, safety and environmental protection in the production process, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

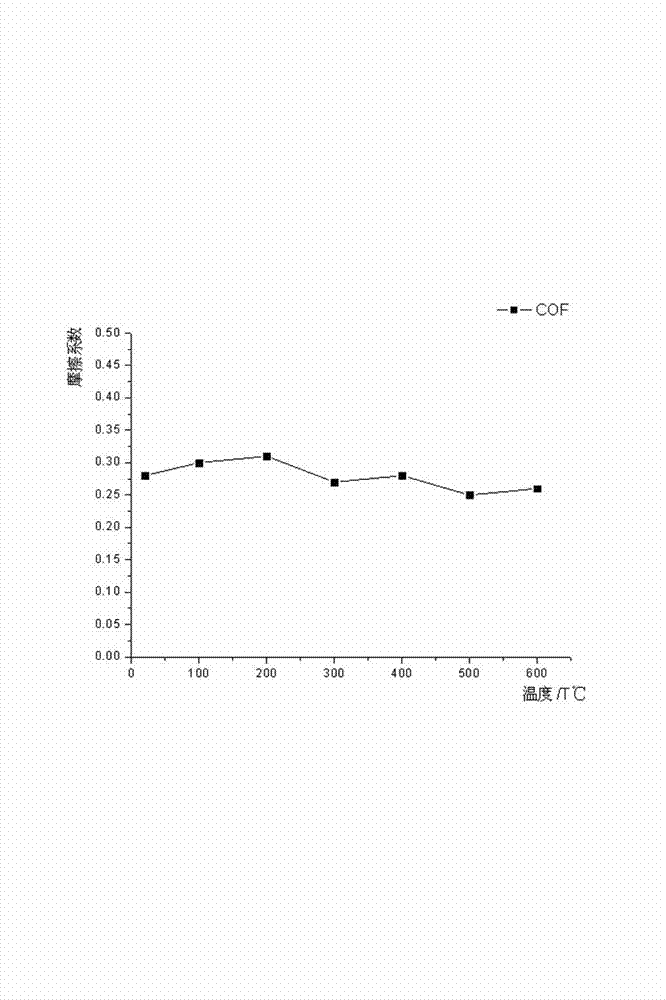

Embodiment 1

[0019] (1) A high-temperature-resistant self-lubricating bearing material is composed as follows by weight percentage:

[0020] MoS 2 15%, CaF 2 5%, Mo10%, Co3%, Cu12%, sodium stearate 3%, the balance is 06Cr19Ni10 stainless steel powder;

[0021] (2) First put the metal powder, lubricant powder and sodium stearate into the roller ball mill and mix them. The mixing method adopts the dry mixing method, the ball-to-material ratio is 5:1, and the time is 3 hours;

[0022] (3) Put the ball-milled mixture into the bearing mold, press it under a pressure of 600Mpa, keep the pressure for 20 minutes during the pressing process, and obtain the bearing blank;

[0023] (4) Put the bearing blank into a vacuum sintering furnace for sintering. The sintering temperature is 1100°C, and the temperature is raised at a heating rate of 10°C / min. After reaching the set temperature, it is kept for 1 hour, and then cooled with the furnace;

[0024] (5) Finally, the obtained bearing blank is subje...

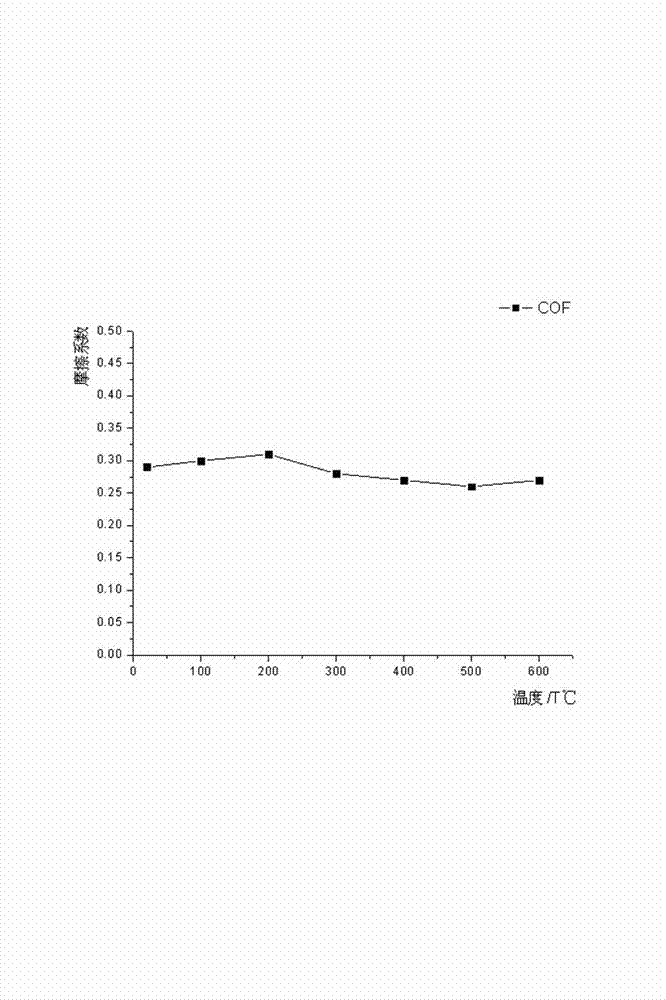

Embodiment 2

[0027] (1) A high-temperature-resistant self-lubricating bearing material is composed as follows by weight percentage:

[0028] MoS 2 20%, CaF 2 5%, Mo8%, Co5%, Cu10%, sodium stearate 3%, the balance is 06Cr19Ni10 stainless steel powder;

[0029] (2) Put the metal powder, lubricant powder and sodium stearate into the roller ball mill and mix them. The mixing method adopts the dry mixing method, the ball-to-material ratio is 5:1, and the time is 3 hours;

[0030] (3) Put the ball-milled mixture into the bearing mold, press it under a pressure of 600Mpa, keep the pressure for 20 minutes during the pressing process, and obtain the bearing blank;

[0031] (4) Put the bearing blank into a vacuum sintering furnace for sintering. The sintering temperature is 1200°C, and the temperature is raised at a heating rate of 10°C / min. After reaching the set temperature, it is kept for 1 hour, and then cooled with the furnace;

[0032] (5) Finally, the obtained bearing blank is subjected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com