Insulation materials for near-human parts of ultra-high voltage substations

A technology of insulating materials and substations, applied in the field of power equipment, can solve the problems of not meeting the application requirements of light weight, and achieve the effects of suppressing space charge accumulation, reducing surface charge accumulation, and optimizing electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

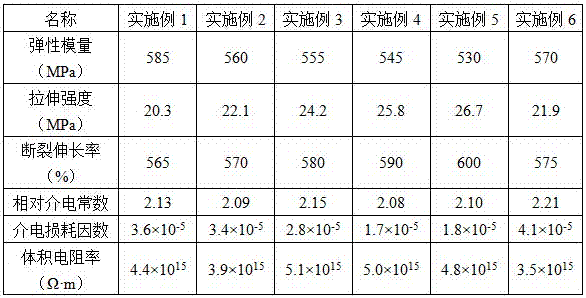

Examples

preparation example Construction

[0036] The present invention also provides a preparation method for the above-mentioned insulating material of the near-human part of the ultra-high voltage substation, comprising the following steps:

[0037] 1) Add 0.1~1 parts by weight of sodium stearate to 15~45 parts by weight of distilled water, place in a magnetic stirrer, stir for 30~60 minutes at 25~35°C, and then add 3~8 parts by weight of nano-nitrided Boron, ultrasonically treated, filtered, and then dried at 50-60°C to obtain surface-modified nano-boron nitride;

[0038] 2) Add the surface-modified nano-boron nitride obtained in step 1) and 100 parts by weight of epoxy resin to the torque rheometer in sequence, and mix them at 160-200°C for 15-30 minutes to obtain nano-boron nitride-modified permanent epoxy resin, spare;

[0039] 3) Add 20-30 parts by weight of methyl vinyl silicone rubber and 0.5-2 parts by weight of nano-aluminum hydroxide to the torque rheometer, and mix at 140-170°C for 10-20 minutes to obtai...

Embodiment 1

[0050] Insulation material for near-person parts of ultra-high-voltage substations. The components and their contents are: 100 parts by weight of epoxy resin, 20 parts by weight of methyl vinyl silicone rubber, 3 parts by weight of nano-boron nitride, and 0.5 parts by weight of nano-aluminum hydroxide , 0.1 parts by weight of sodium stearate, 15 parts by weight of distilled water, 0.5 parts by weight of potassium hexatitanate whiskers, a mixture of silicon dioxide, silicon carbide, titanium dioxide and zinc oxide with a particle size of 20-50 nm (silicon dioxide: silicon carbide : The weight ratio of titanium dioxide: zinc oxide is 1:0.8:1.2:1.5) 5 parts by weight, 5 parts by weight of acetone, 0.5 parts by weight of maleic anhydride grafted polyethylene, 1 part by weight of magnesium hydroxide, and 0.5 parts by weight of antioxidant 300 parts by weight, 3 parts by weight of dibenzoyl peroxide.

[0051] A method for preparing an insulating material near a human part of an ultr...

Embodiment 2

[0059] Insulation material for near-human parts of ultra-high-voltage substations. The components and their contents are: 100 parts by weight of epoxy resin, 22 parts by weight of methyl vinyl silicone rubber, 4 parts by weight of nano-boron nitride, and 0.8 parts by weight of nano-aluminum hydroxide , 0.3 parts by weight of sodium stearate, 20 parts by weight of distilled water, 0.6 parts by weight of potassium hexatitanate whiskers, a mixture of silicon dioxide, silicon carbide, titanium dioxide and zinc oxide with a particle size of 20-50 nm (silicon dioxide: silicon carbide : The weight ratio of titanium dioxide: zinc oxide is 1:0.8:1.2:1.5) 8 parts by weight, 6 parts by weight of formaldehyde, 15 parts by weight of maleic anhydride grafted polypropylene, 2 parts by weight of magnesium hydroxide, and the antioxidant BBM is 0.6 Parts by weight, 3.5 parts by weight of triallyl isocyanurate.

[0060] A method for preparing an insulating material near a human part of an ultra-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com