Copolymerized polyimide nanofiber nonwoven and preparation method and application thereof

A technology of co-polyimide and co-polyamic acid, which is applied in the fields of non-woven fabrics, fiber chemical characteristics, textiles and papermaking, and can solve problems such as explosion, battery short circuit, thermal runaway, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

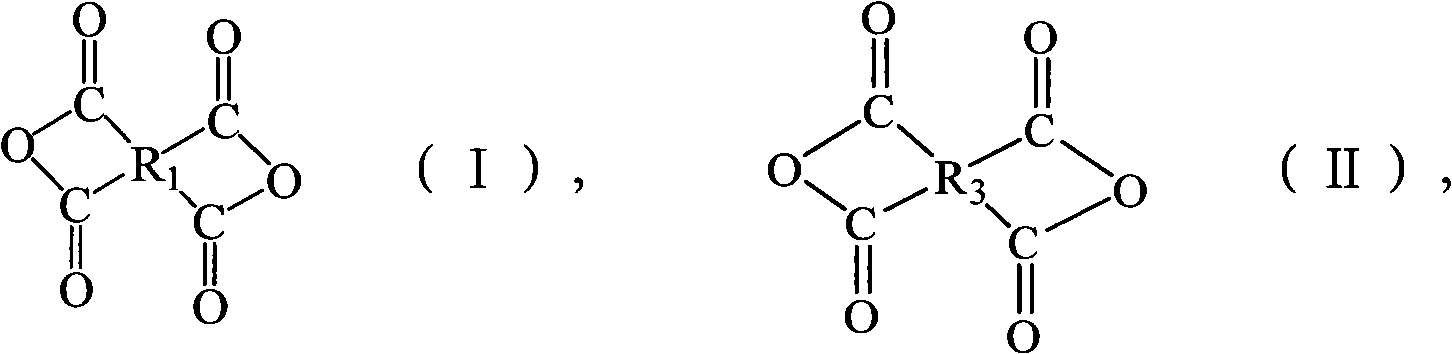

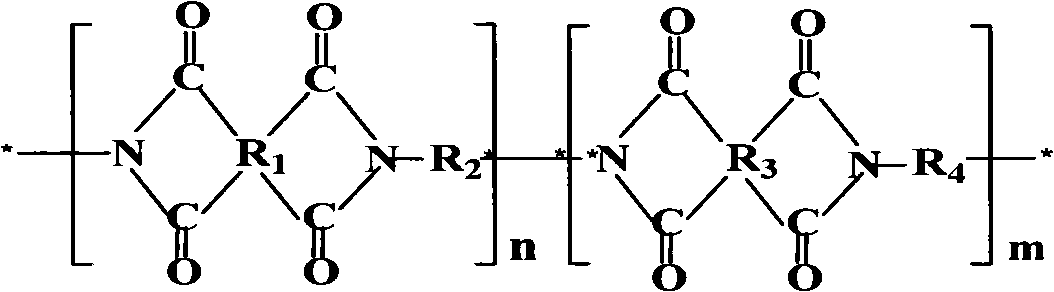

[0059] A kind of preparation method of polyimide nanofiber nonwoven of the present invention, its step comprises:

[0060] (1) Based on the principle that the total molar amount of dianhydride functional groups is equal to the total molar amount of diamine functional groups, take an appropriate amount of a dianhydride monomer and two kinds of diamine monomers or mix two kinds of dianhydride monomers. Mix one kind of diamine monomer or two kinds of dianhydride monomers and two kinds of diamine monomers, put them into the polymerization reactor together with an appropriate amount of solvent, and stir for a period of time. Obtain copolyamic acid (polyimide precursor) solution, and this copolyamic acid solution is implemented electrospinning in high-voltage electric field, is collector with stainless steel roller, collects and obtains copolyamic acid nanofiber porous film or Non-woven. Wherein the solvent used is preferably one of N,N-dimethylformamide (DMF) and N,N-dimethylaceta...

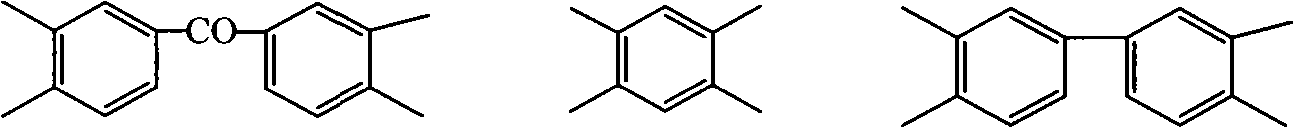

Embodiment 1

[0064] The selected comonomers are a tetraacid dianhydride monomer and two diamine monomers. Mix the purified biphenyldianhydride (BPDA), p-phenylenediamine (PPD) and diphenyl ether diamine (ODA) with a molar ratio of 1:0.5:0.5, and mix them with N,N-dimethylformamide ( DMF) as a solvent, carried out according to the above reaction steps. In the reaction step (1), the temperature of the reaction kettle of this embodiment is 10°C, and the stirring reaction time is 6 hours; the electric field strength of the high-voltage electric field used in the electrospinning process is 300kV / m; Heating from room temperature to 200°C at a heating rate of 1 / min, staying at this temperature for 30 minutes, then heating to 350°C at a heating rate of 5°C / min, and staying at 350°C for 30 minutes, then cutting off the power supply and cooling to room temperature naturally.

[0065] Performance characterization: The mass concentration of the copolymerized polyamic acid (polyimide precursor) soluti...

Embodiment 2

[0067] The selected comonomers are a tetraacid dianhydride monomer and two diamine monomers. The purified pyromellitic dianhydride (PMDA), diphenyl ether diamine (ODA) and biphenyl diamine (Bz) in a molar ratio of 1:0.6:0.4 were mixed with N,N-dimethylformamide ( DMF) is made solvent, reacts by above-mentioned steps, and in reaction step (1), the temperature of this embodiment reactor is 5 ℃, and the stirring reaction time is 6 hours; In the step (2), the heating program is heated from room temperature to 250°C at a heating rate of 20°C / min, staying at this temperature for 30 minutes, then heating to 370°C at a heating rate of 5°C / min, and staying at 370°C for 30 minutes , then cut off the power supply and let it cool down to room temperature naturally.

[0068] Performance characterization: The mass concentration of the copolymerized polyamic acid (polyimide precursor) solution is 5%, the absolute viscosity is 4.8Pa·S, the diameter of the copolymerized polyamic acid nanofibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absolute viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com