Heat-dissipating double-sided adhesive tape with ultrahigh heat conductivity coefficient

A double-sided tape, thermal conductivity technology, applied in the direction of adhesive, cooling/ventilation/heating transformation, film/flake adhesive, etc. It can reduce the probability of graphite cracking, facilitate graphite cutting, and reduce volume shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

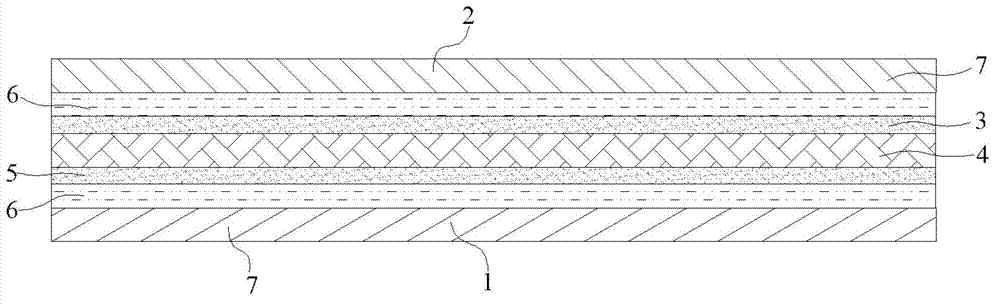

[0034] Embodiment 1: A heat-dissipating double-sided tape with ultra-high thermal conductivity, the heat-dissipating double-sided tape is attached between the heat-dissipating surface and the heating component, and the heat-dissipating double-sided tape includes a light-peelable PET film 1 and a heavy-peelable PET film 1 Film 2, a first heat-conducting adhesive layer 3, a graphite layer 4 and a second heat-conducting adhesive layer 5 are sequentially arranged between the light-peelable PET film 1 and the heavy-peelable PET film 2; the graphite layer 4 passes through the following process The method obtains, and this technological method comprises the following steps:

[0035] Step 1. Add ethylene glycol or triethylamine to the polyamic acid solution, stir well and apply it on a glass substrate layer or an organic substrate layer;

[0036] Step 2, under the protection of nitrogen, keep the temperature at 80°C for 0.95 hours;

[0037] Step 3, place in an oven in a vacuum enviro...

Embodiment 2

[0048] Embodiment 2: A heat-dissipating double-sided tape with ultra-high thermal conductivity, the heat-dissipating double-sided tape is attached between the heat-dissipating surface and the heating component, and the heat-dissipating double-sided tape includes a light-peelable PET film 1 and a heavy-peelable PET film 1 Film 2, a first heat-conducting adhesive layer 3, a graphite layer 4 and a second heat-conducting adhesive layer 5 are sequentially arranged between the light-peelable PET film 1 and the heavy-peelable PET film 2; the graphite layer 4 passes through the following process The method obtains, and this technological method comprises the following steps:

[0049] Step 1. Add viscosity-increasing and other additives to the polyamic acid solution, stir well and apply it on a substrate layer;

[0050] Step 2, under the protection of nitrogen, keep the temperature at 80°C for 1 hour;

[0051] Step 3, place in an oven in a vacuum environment, keep the temperature at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com