Alicyclic-containing polyimide film and preparation method thereof

A polyimide film and alicyclic technology, which is applied in the field of polyimide film and its preparation, can solve the problems of low reactivity, high cost, and obstacles to popularization and application, and achieve mild reaction conditions, simple operation, and convenient source Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

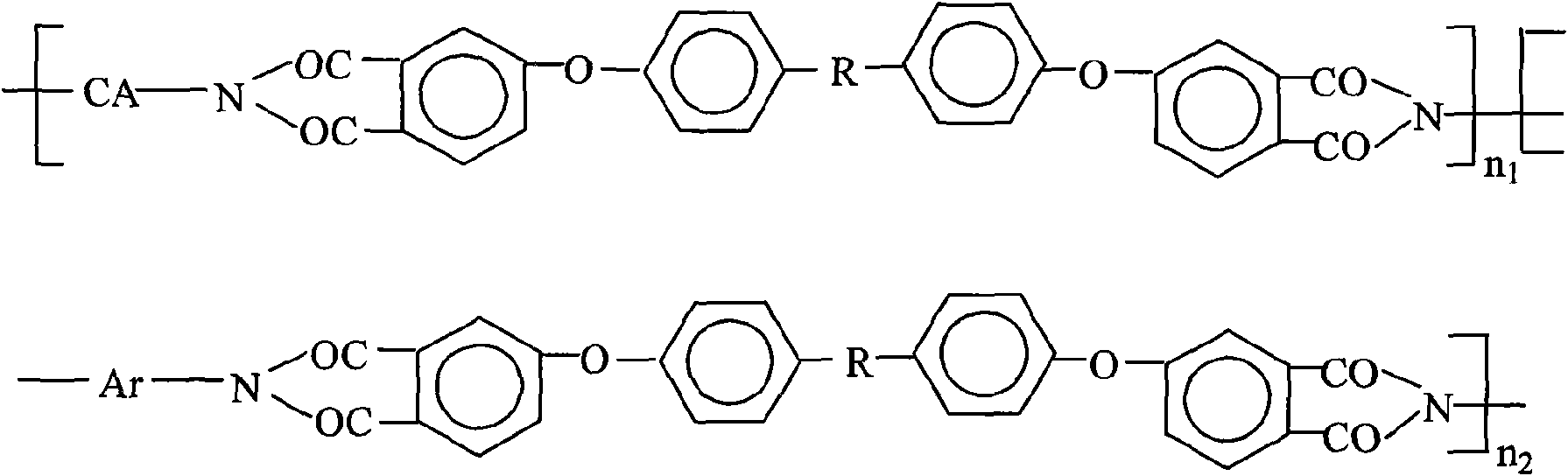

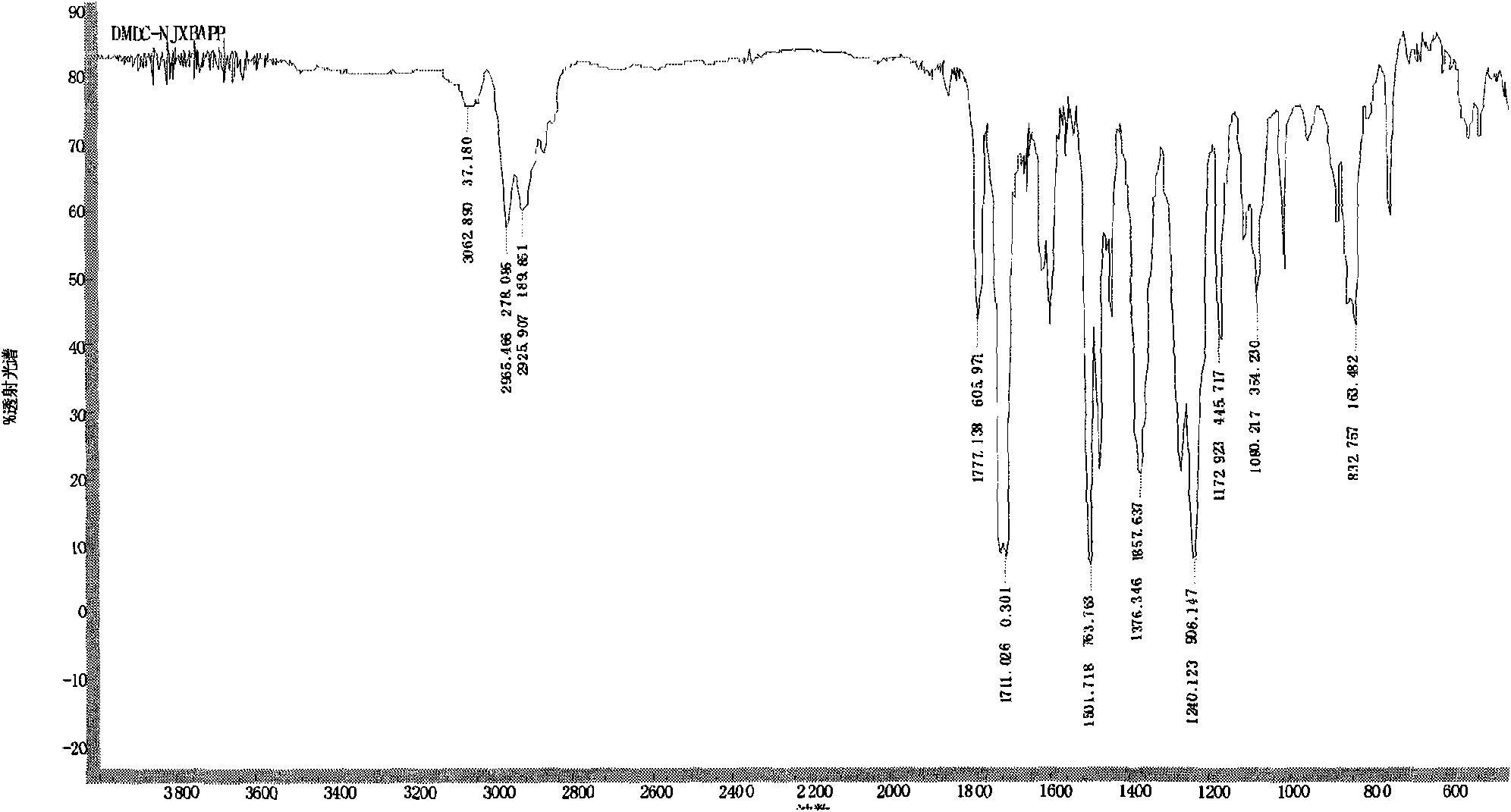

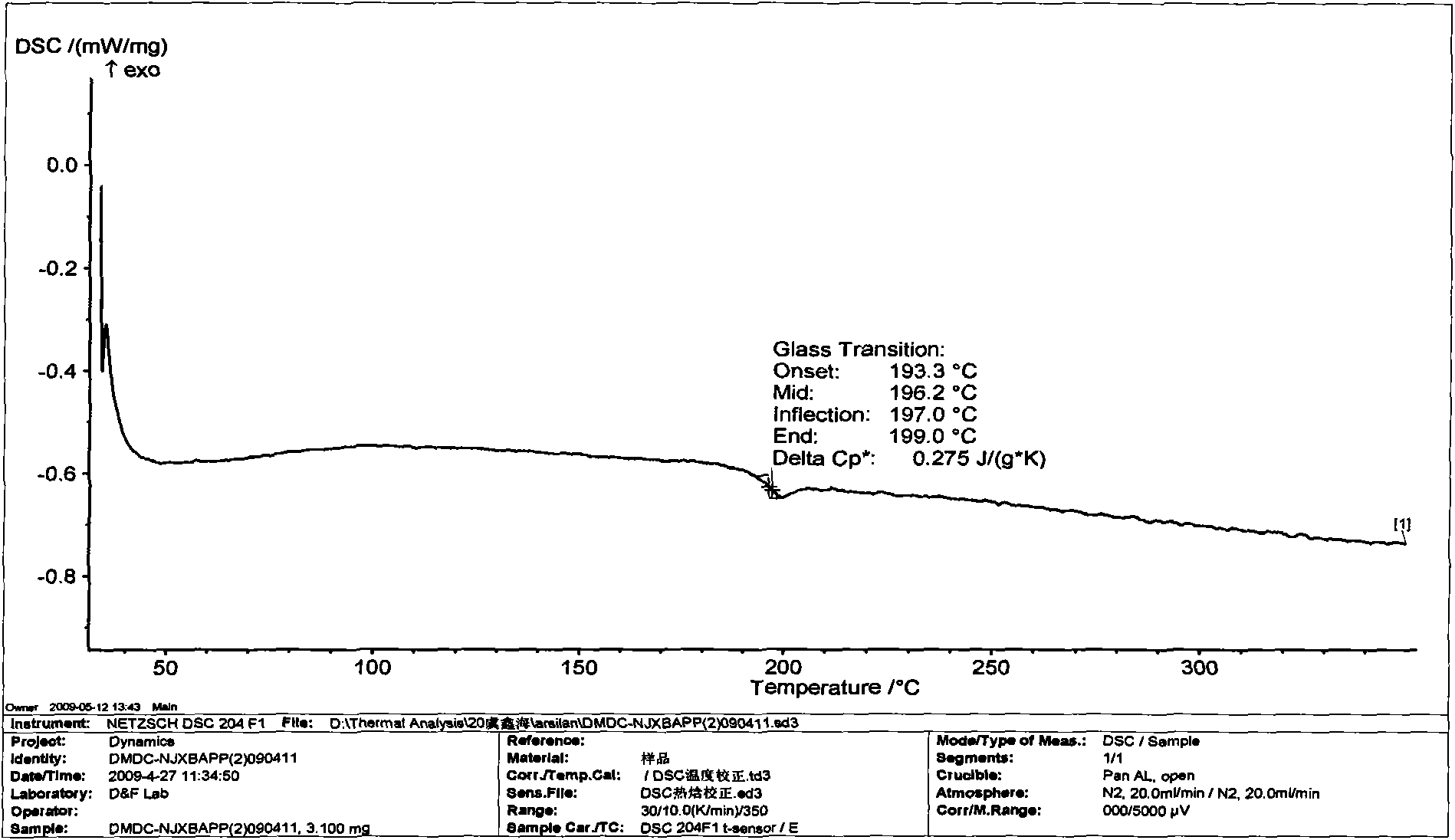

Method used

Image

Examples

Embodiment 1

[0076] 23.8 grams (0.1 moles) of 3,3'-dimethyl-4,4'-diaminodicyclohexylmethane (DMDC), 41.0 grams (0.1 moles) of 2,2-bis[4-(4-amino Phenoxy) phenyl] propane (NJXBAPP) and 510 milliliters of N, N-dimethylacetamide were put into the reaction kettle, stirred at room temperature, after completely dissolving, 104.1 grams (0.2 moles) of 2,2-bis [4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride (BPADA), stirred at room temperature, after completely dissolving, the reaction was maintained for 1 hour to obtain homogeneous transparent viscous alicyclic poly Amic acid solution.

[0077] Utilize N,N-dimethylacetamide solvent to adjust the viscosity of the polyamic acid solution so that it is between 30 seconds and 60 seconds (No. 4 viscosity cup), form a film in a casting machine, and heat up to remove Remove organic solvent (recovery and reuse) and carry out dehydration thermal imidization reaction, wherein, the specific dehydration thermal imidization process is: heating from room te...

Embodiment 2

[0082]23.8 g (0.1 mole) of 3,3'-dimethyl-4,4'-diaminodicyclohexylmethane (DMDC), 54.7 g (0.1 mole) of 2,2-bis[4-(2-tri Fluoromethyl-4-aminophenoxy group) phenyl] propane (BAPP-2TF) and 910 milliliters of N, N-dimethylformamide are put into reaction kettle, stir at room temperature, after dissolving completely, add 104.1 grams ( 0.2 mol) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propanedianhydride (BPADA), stirred at room temperature, after completely dissolving, the reaction was maintained for 3 hours to obtain a homogeneous Transparent viscous polyamic acid solution containing alicyclic ring.

[0083] Utilize N,N-dimethylformamide solvent to adjust the viscosity of the polyamic acid solution so that it is between 30 seconds and 60 seconds (No. 4 viscosity cup), form a film in a casting machine, and heat up to remove Remove organic solvent (recovery and reuse) and carry out dehydration thermal imidization reaction, wherein, the specific dehydration thermal imidization process...

Embodiment 3

[0088] 23.8 g (0.1 mole) of 3,3'-dimethyl-4,4'-diaminodicyclohexylmethane (DMDC), 65.4 g (0.1 mole) of 2,2-bis[4-(2-tri Fluoromethyl-4-aminophenoxy)phenyl]hexafluoropropane (BAPFP-2TF) and 773 ml of N-methyl-2-pyrrolidone were put into the reaction kettle, stirred at room temperature, after completely dissolving, 104.1 g of (0.2 moles) of 2,2-bis[4-(3,-dicarboxyphenoxy)phenyl]propane dianhydride (BPADA), stirred at room temperature, and after completely dissolving, the reaction was maintained for 2 hours to obtain a homogeneous Transparent viscous polyamic acid solution containing alicyclic ring.

[0089] Use N-methyl-2-pyrrolidone solvent to adjust the viscosity of the polyamic acid solution so that it is between 30 seconds and 60 seconds (No. 4 viscosity cup), form a film in a casting machine, and heat up to remove Organic solvent (recovery and reuse) and dehydration heat imidization reaction, wherein, the specific dehydration heat imidization process is: heating from room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com