Method for preparing polyimide/ silicon dioxide hollow micro-sphere composite film

A technology of silica and hollow microspheres, which is applied in the field of organic-inorganic hybrid material preparation, can solve the problems of difficult processing, easy hydrolysis, large thermal expansion coefficient, etc., and achieves the effect of reducing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of silica hollow microspheres:

[0025] Add 5g of styrene, 1.5g of polyvinylpyrrolidone (PVP), 5g of water, 0.2g of azobisisobutyronitrile (AIBN) and 22.5g of ethanol into a 250mL four-necked flask, and stir for 30 minutes under nitrogen protection. After raising the temperature to 70-80°C for 1-2 hours, quickly add 5g of styrene, 22.5g of ethanol and 1-4g of methacryloyloxyethyltrimethylammonium chloride (MTC), under nitrogen protection After reacting for 25 hours, cool to 50°C, then add 6-12g tetraethyl orthosilicate (TEOS) and 1-4mL ammonia water to react for 1 hour, and centrifuge to obtain hollow silica microspheres with a particle size of 200-1000nm.

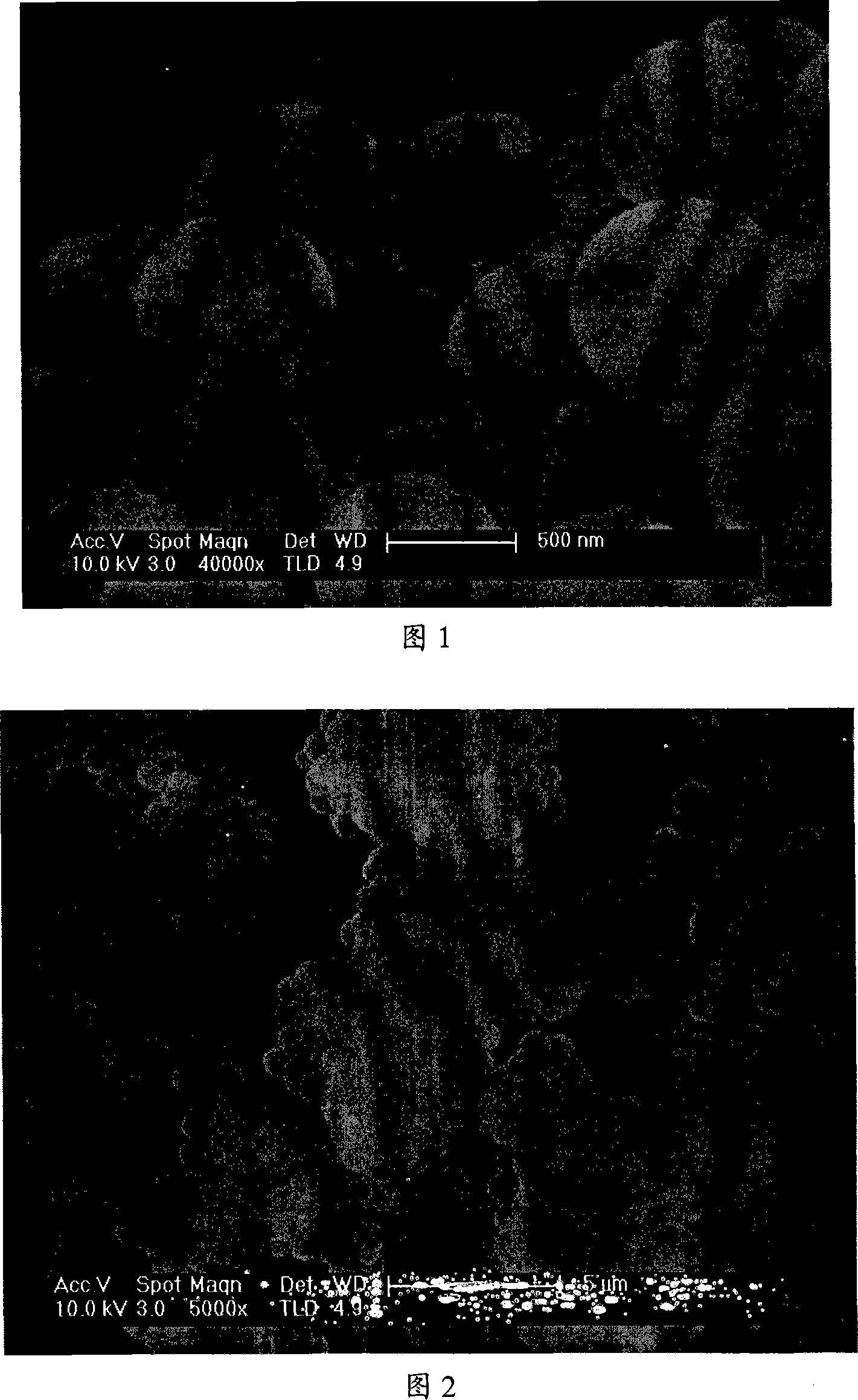

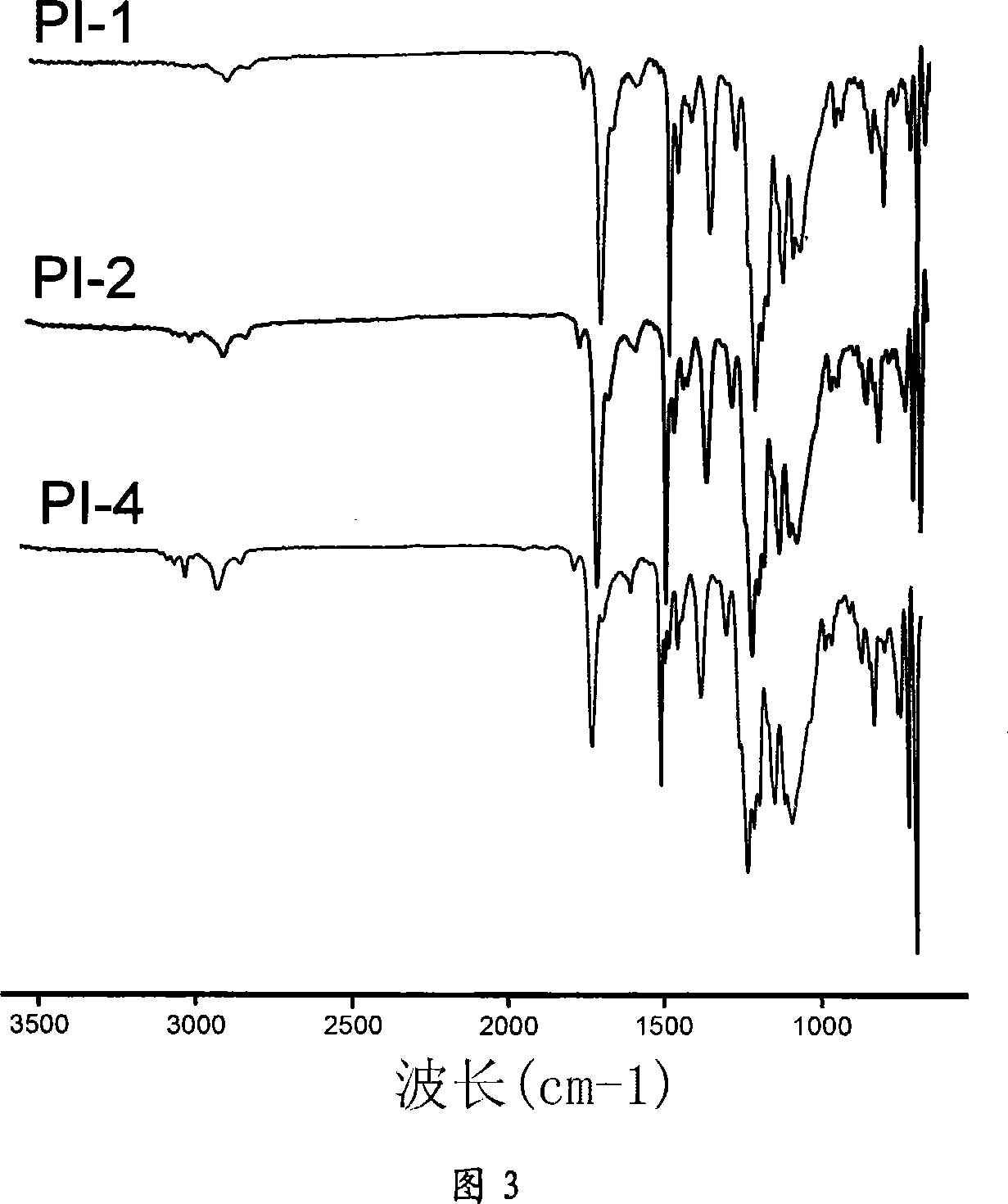

[0026] Fig. 1 and Fig. 2 are the electron micrographs of the silica hollow microspheres prepared by this method, and it can be clearly seen that the silica microspheres prepared by this method are indeed hollow. The hollow microspheres introduced in this way utilize the dielectric constant of air to be ...

Embodiment 2

[0028] Preparation of polyimide / silica hollow microsphere composite film:

[0029] 10 g of silicon dioxide hollow microspheres were added to 105 ml of ethanol solution with a mass concentration of 95%. Use 50W, 40kHz ultrasonic to disperse for 20 minutes every hour, then add 2g of silane coupling agent, stir and react at 60°C for 5h, stirring speed is 500-1000 rpm, centrifuged at 4500 rpm 10 minutes, wash, dry.

[0030] 0.52g of 2,2-bis[4-(3',4'-dicarboxyphenoxy)phenyl]propane dianhydride (BPADA) and 0.438g of bis[3,5-dimethyl-4 -(4-Amino)phenol]methane (BDAPM) was added to 8.622 g of N-methyl-2-pyrrolidone (NMP) to prepare a solution with a solid content of 10% (wt / wt). Add 0.1064g of silica hollow microspheres modified by a silane coupling agent, the silica hollow microspheres being 10% of the mass of the composite film, into the above NMP solution, disperse with 50W, 40kHz ultrasound, and at room temperature The reaction was continuously stirred for 24 hours to obtain a ...

Embodiment 3

[0032] 10 g of silicon dioxide hollow microspheres were added to 105 ml of ethanol solution with a mass concentration of 95%. After ultrasonic dispersion, 2 g of silane coupling agent was added, stirred and reacted at 80°C for 5 hours at a stirring speed of 500-1000 rpm, centrifuged at 4500 rpm for 10 minutes, washed and dried.

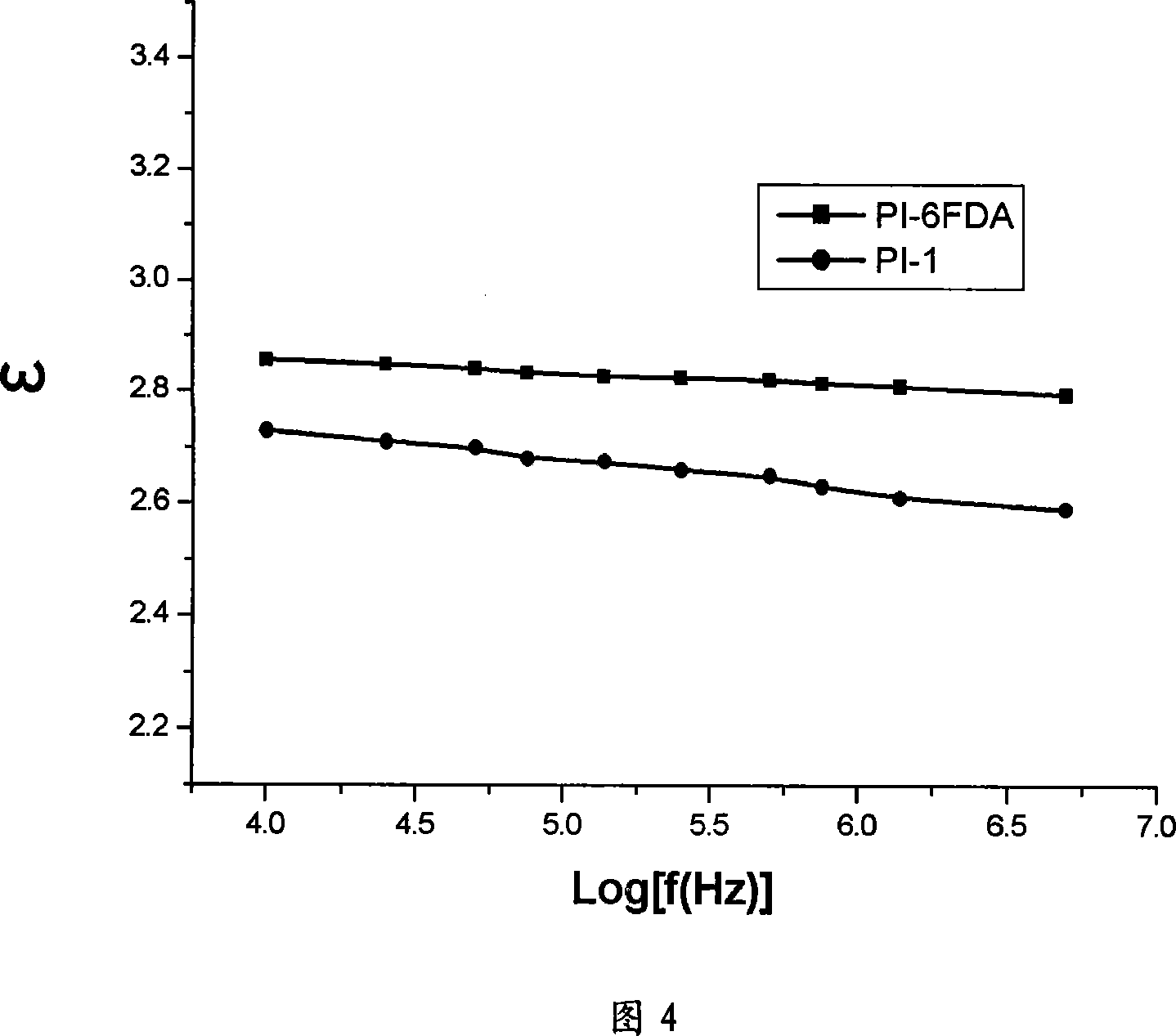

[0033]0.444g of 4,4'-(hexafluoropropylene)bis-phthalic anhydride (6FDA) and 0.438g of BDAPM were added to 7.938g of NMP to prepare a solution with a solid content of 10% (wt / wt). Add 0.378g of silica hollow microspheres modified by a silane coupling agent, the silica hollow microspheres being 30% of the mass of the composite film, into the above NMP solution, disperse with 50W, 40kHz ultrasound, and at room temperature The reaction was continuously stirred for 24 hours to obtain a polyamic acid viscous liquid. Take an appropriate amount of polyamic acid viscous solution and pour it on the glass plate mold. Place the mold at 80° C. for 2 hours in vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com