Lithium-ion battery cathode material lini 0.6-x co 0.2 mn 0.2 al x o 2-y f y and its preparation method

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor electrochemical performance, improve discharge specific capacity, improve cycle performance, and improve reversible de-intercalation/intercalation capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

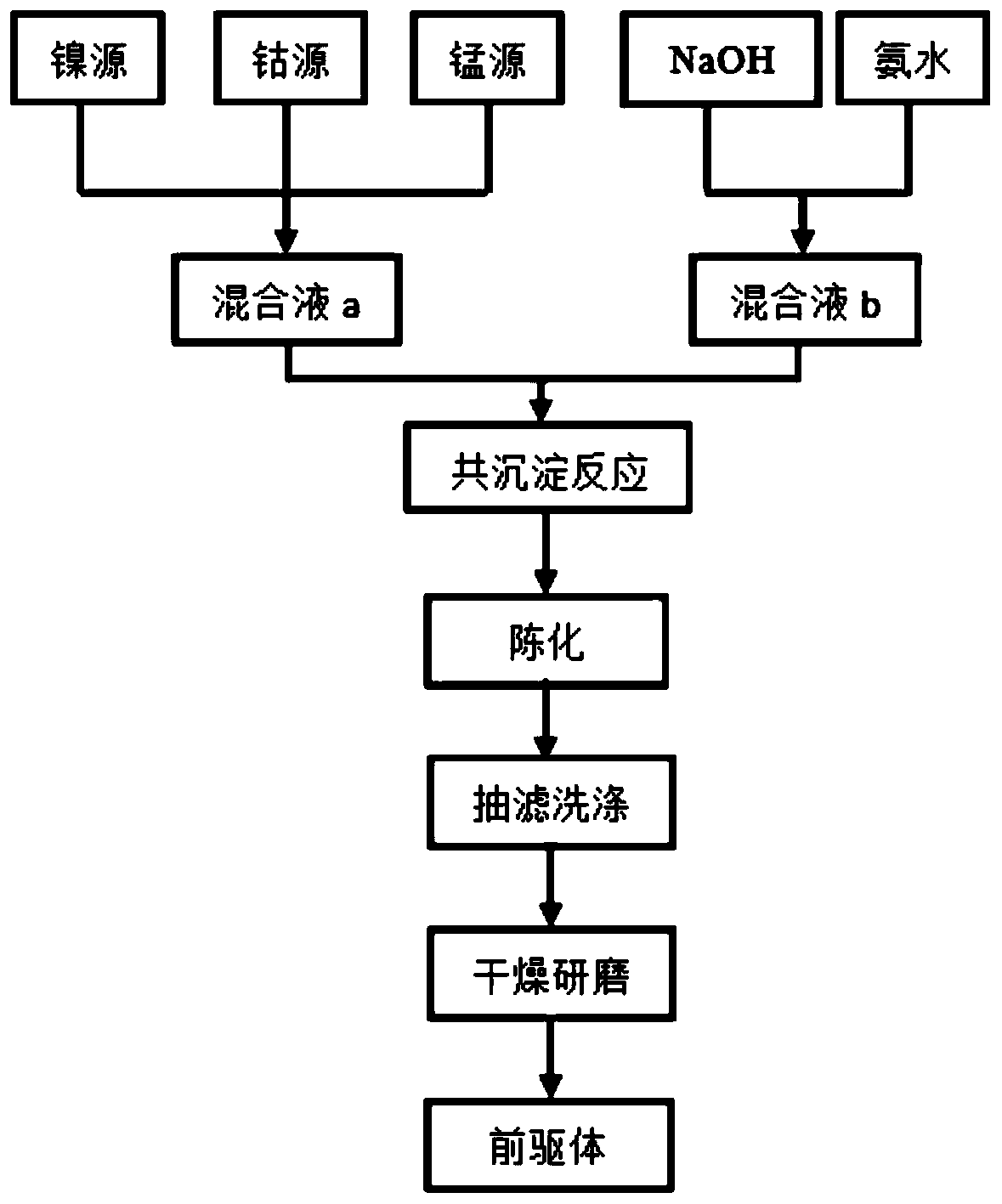

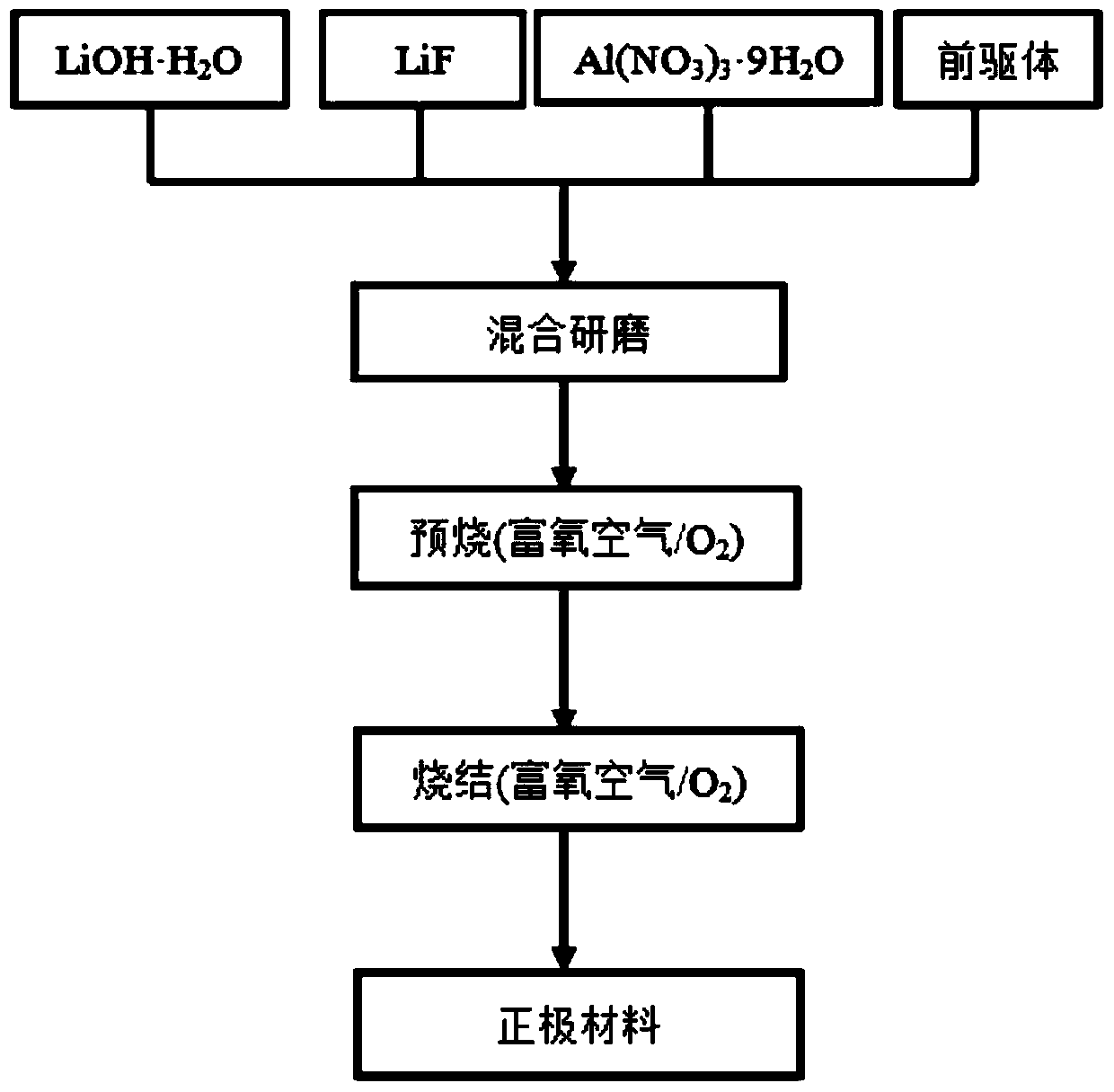

[0036] The present embodiment provides lithium-ion battery cathode material LiNi 0.6-x co 0.2 mn 0.2 Al x o 2-y f y , x=0.01, y=0.02; that is, Al and F doping amounts are 0.01 and 0.02 respectively, and nickel sulfate, cobalt sulfate, and manganese sulfate are weighed according to the molar ratio Ni:Co:Mn=5.9:2:2, and are formulated into 1.0 mol / L sulfate mixed solution a; mix sodium hydroxide solution and ammonia water to form a mixed solution with a concentration of sodium hydroxide of 2.0 mol / L and a concentration of ammonia water of 0.5 mol / L, which is recorded as solution b; the prepared two solutions a and b are slowly added dropwise into the reaction tank in parallel and continuously stirred, and the pH is adjusted with ammonia water so that the pH value is controlled at about 11. Then the resultant was suction-filtered and washed several times in a circulating water vacuum pump until no sulfate ions were detected in the barium chloride solution, and finally it was...

Embodiment 2

[0040] The present embodiment provides lithium-ion battery cathode material LiNi 0.6-x co 0.2 mn 0.2 Al x o 2-y f y , x=0.02, y=0.04; That is, Al, F doping amounts are 0.02 and 0.04 respectively, take nickel sulfate, cobalt sulfate, manganese sulfate according to molar ratio Ni:Co:Mn=5.8:2:2, be mixed with 1.0 mol / L sulfate mixed solution a; mix sodium hydroxide solution and ammonia water to form a mixed solution with a concentration of sodium hydroxide of 2.0 mol / L and a concentration of ammonia water of 0.5 mol / L, which is recorded as solution b; the prepared two solutions a and b are slowly added dropwise into the reaction tank in parallel and continuously stirred, and the pH is adjusted with ammonia water so that the pH value is controlled at about 11. Then the resultant was filtered and washed several times in a circulating water vacuum pump until no sulfate ions were detected in the barium chloride solution, and finally it was dried and ground to obtain a precursor ...

Embodiment 3

[0043] The present embodiment provides lithium-ion battery cathode material LiNi 0.6-x co 0.2 mn 0.2 Al x o 2-y f y, x=0.01, y=0.04; that is, Al and F doping amounts are 0.01 and 0.04 respectively, and nickel sulfate, cobalt sulfate, and manganese sulfate are weighed according to the molar ratio Ni:Co:Mn=5.9:2:2, and are formulated to be 1.0 mol / L sulfate mixed solution a; mix sodium hydroxide solution and ammonia water to form a mixed solution with a concentration of sodium hydroxide of 2.0 mol / L and a concentration of ammonia water of 0.5 mol / L, which is recorded as solution b; the prepared two solutions a and b are slowly added dropwise into the reaction tank in parallel and continuously stirred, and the pH is adjusted with ammonia water so that the pH value is controlled at about 11. Then the resultant was suction-filtered and washed several times in a circulating water vacuum pump until no sulfate ions were detected in the barium chloride solution, and finally it was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com