Ion doping and surface cladding jointly-modified lithium ion battery anode material and preparation method thereof

A lithium-ion battery, ion doping technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of positive electrode structure damage, easy redox reaction, thermodynamic instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In some embodiments, there is also provided the above-mentioned ion doping and surface coating co-modified lithium-ion battery positive electrode material preparation method, comprising the following steps:

[0043] (1) According to the general formula Li(Ni x co y mn 1-x-y ) 1-a Nb a o 2 In the stoichiometric ratio, weigh nickel salt, cobalt salt, manganese salt, lithium salt, Nb compound, add to deionized water, and add 2.620g citric acid and 5.012g ethylene glycol with 500mL deionized water, dissolve to prepare into a sol, evaporated to dryness into a gel, dried, and placed in a sintering furnace, calcined at 750-1000°C for 6-15h, crushed, and ground to obtain Li(Ni x co y mn 1-x-y ) 1-a Nb a o 2 material, wherein, a is 0.005~0.2; or according to the general formula Li(Ni x co y mn 1-x-y ) 1-a Nb a o 2 For the stoichiometric ratio, weigh the compounds of nickel salt, cobalt salt, manganese salt, lithium salt, and Nb, and mix them well. , grind to get...

Embodiment 1

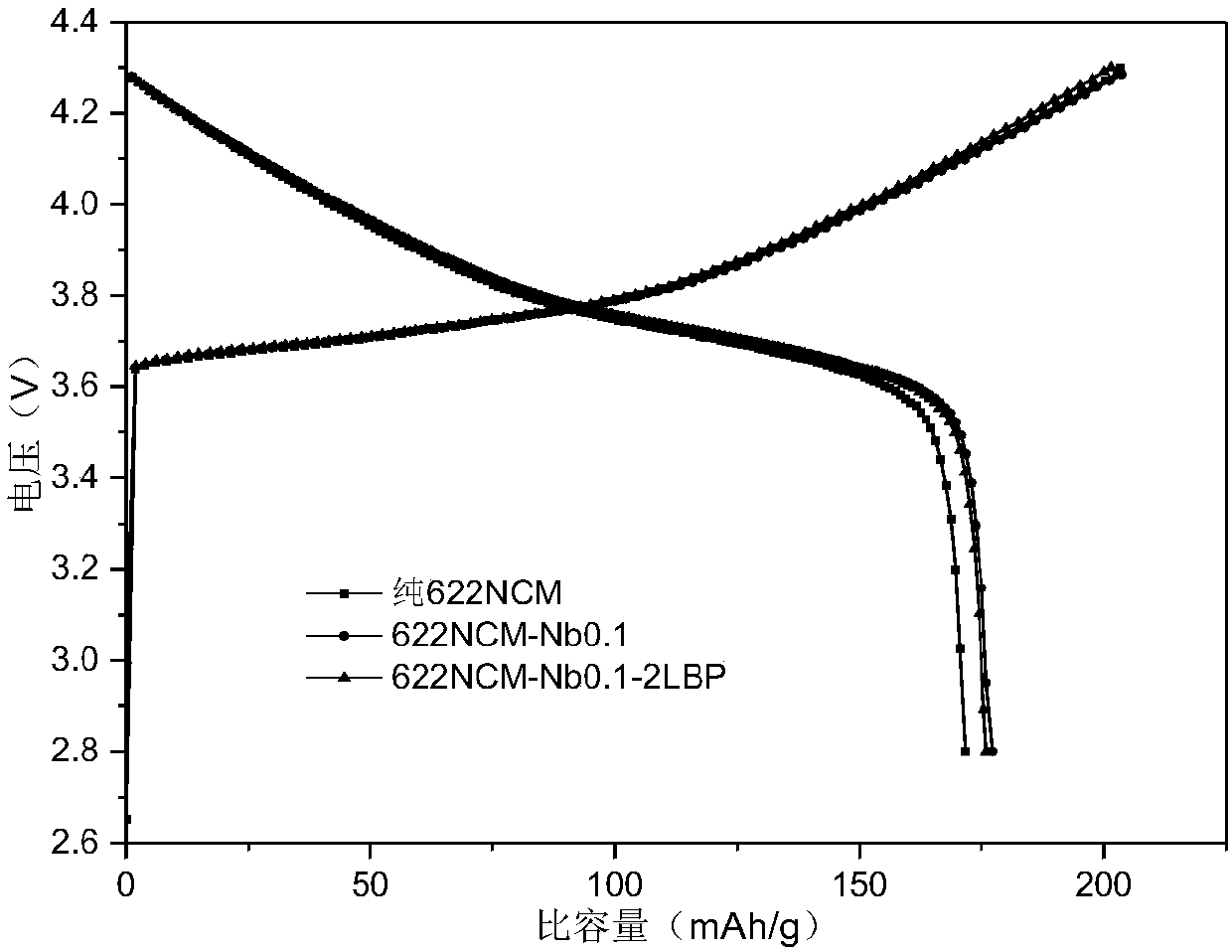

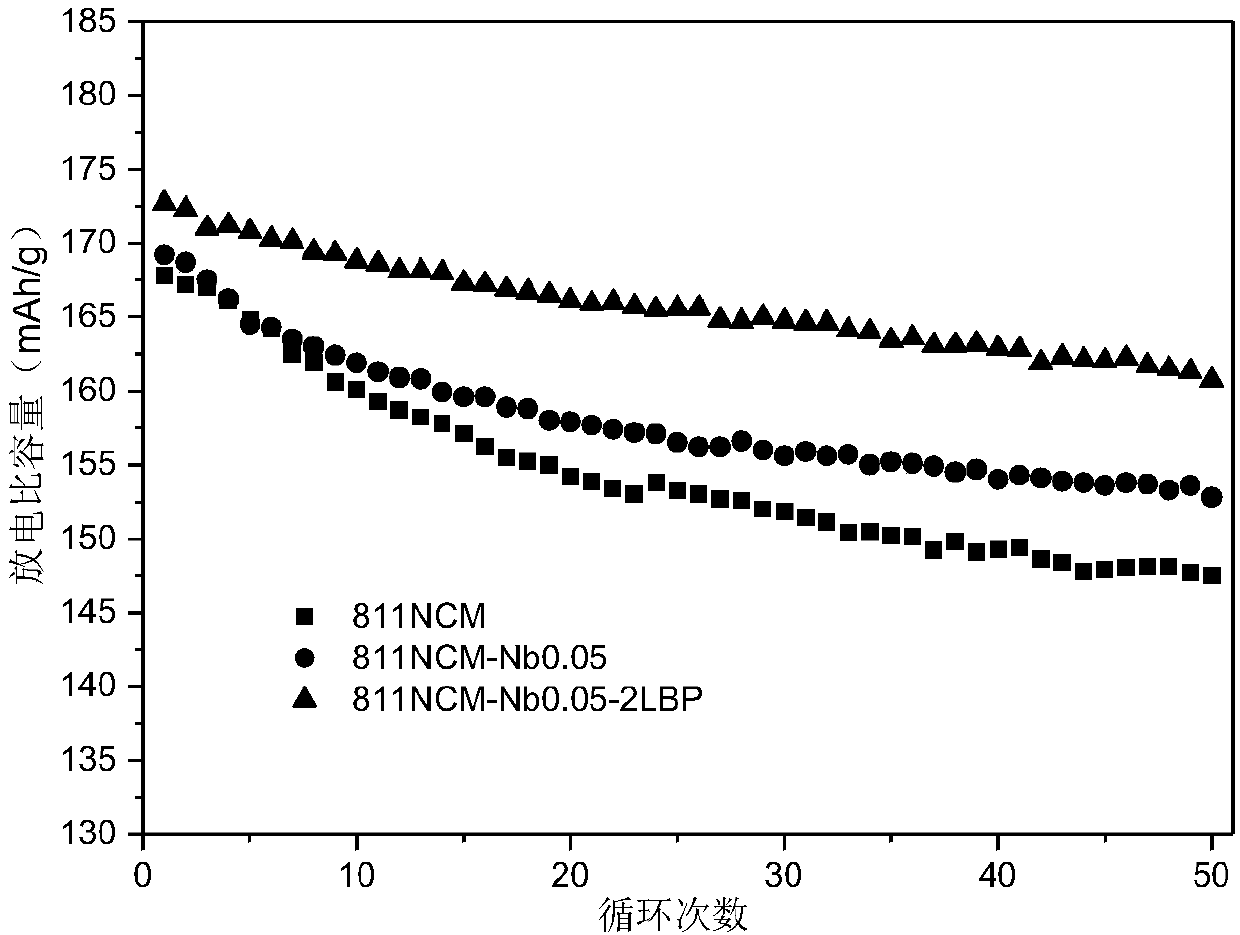

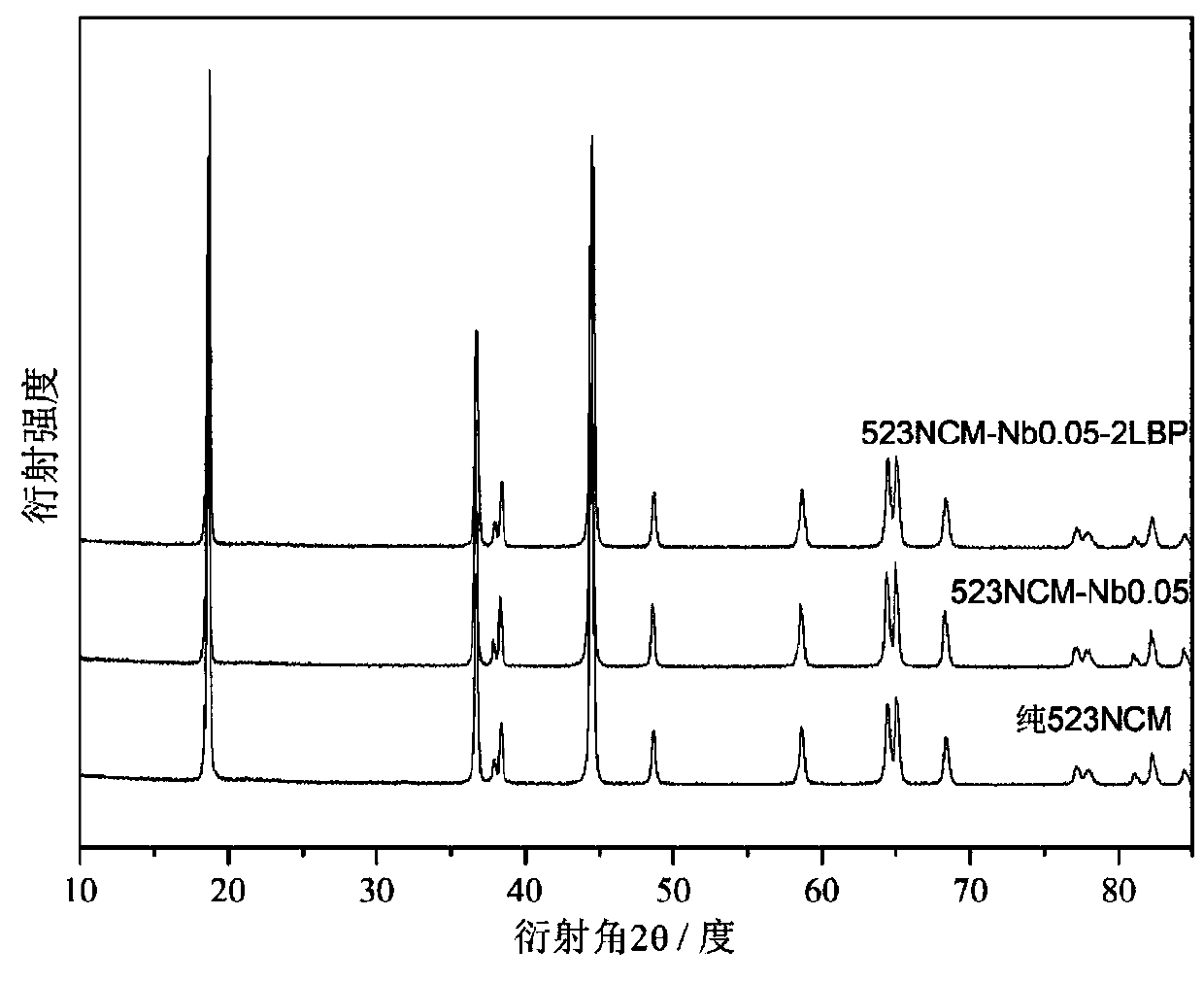

[0052] Preparation of Li(Ni) coated with 2% LBP 0.6 co 0.2 mn 0.2 ) 0.95 Nb 0.05 o 2 Positive electrode material, its concrete steps are as follows:

[0053] (1) Take by weighing 4.081g lithium acetate, 5.674g nickel acetate, 1.893g cobalt acetate, 1.863g manganese acetate, 1.076g niobium oxalate, 2.620g citric acid and 5.012g ethylene glycol all dissolve in the deionized water of 500ml, in Stir and heat in a water bath with a set temperature of 80°C, evaporate to dryness to form a gel, and place it in an oven at 120°C for 6 hours. The dried gel was ground into a crucible and placed in a tube furnace, and sintered at 850°C for 12h in an air atmosphere. The sintered block was ground and crushed to obtain a 622NCM material with a Nb-doped molarity of 0.05.

[0054] (2) Weigh lithium metaborate, boric acid and ammonium dihydrogen phosphate according to the stoichiometric ratio of LBP, and dissolve them in a mixture of 90 mL ethanol and 30 mL water. Add the materials obtai...

Embodiment 2

[0057] Preparation of Li(Ni) coated with 2% LBP 0.6 co 0.2 mn 0.2 ) 0.9 Nb 0.1 o 2 Positive electrode material, the present embodiment differs from Example 1 in that the quality of each metal salt taken in step (1) is respectively 4.081g lithium acetate, 5.375g nickel acetate, 1.793g cobalt acetate, 1.764g manganese acetate, 2. 152 g niobium oxalate. Other operating steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com