Nickel-cobalt-manganese ternary precursor, positive electrode material and preparation method

A nickel-cobalt-manganese ternary, precursor technology, applied in positive electrodes, chemical instruments and methods, nickel compounds, etc., can solve the problems of micro-cracks, reducing capacity retention rate, accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

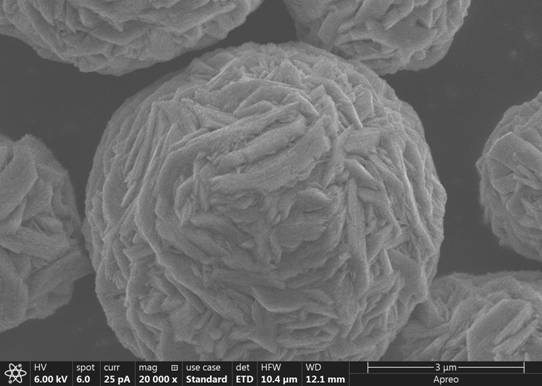

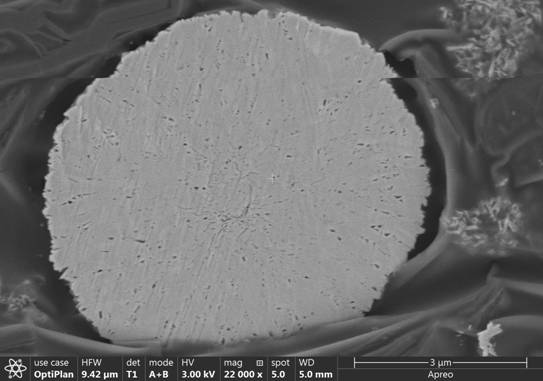

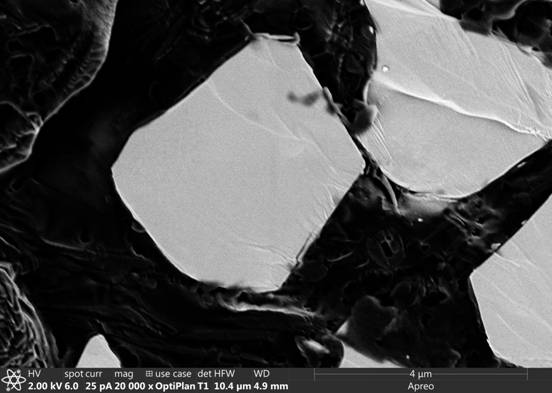

Image

Examples

Embodiment 1

[0036] The preparation of nickel-cobalt-manganese ternary precursor comprises the following steps:

[0037] (1) Prepare nickel-cobalt-manganese mixed salt solution according to the molar ratio of Ni:Co:Mn=80.80±0.5 : 9.59±0.3: 9.59±0.3. Prepare 24m 3 For the nickel-cobalt-manganese mixed salt solution with a total metal ion concentration of 120g / L, the volumes of qualified single-salt nickel sulfate, cobalt sulfate, and manganese sulfate solutions to be added are 10497L, 1341L, and 805L respectively, and the remaining volumes are supplemented with water.

[0038] (2) Preparation of zirconium salt and magnesium salt solution

[0039] Zr is added in the form of doping, and the doping amount is 4885ppm. Accurately prepare 500L, 0.1 mol / L Zr doping solution: weigh 50mol (27.36kg) of Zr(SO 4 ) 4 4H 2 O powder was dissolved in 500 L of water to prepare a 0.1 mol / L doped Zr solution. The zirconium salt solution used for doping and coating is the same concentration of zirconium ...

Embodiment 2

[0074] The preparation of nickel-cobalt-manganese ternary precursor comprises the following steps:

[0075] (1) According to the ratio of Ni:Co:Mn=96.93±0.5 : 1.53±0.3:1.53±0.3, a nickel-cobalt-manganese mixed salt solution with a total metal ion concentration of 121g / L was prepared. Prepare 24m 3 Qualified nickel-cobalt-manganese mixed salt solution, the volumes of qualified single-salt nickel sulfate, cobalt sulfate, and manganese sulfate solutions are 12531.03L, 212.90L, and 127.82L, respectively. The remaining volume was made up with water.

[0076] (2) Preparation of zirconium salt and magnesium salt solution

[0077] Zr is added in the form of doping, and the doping amount is 9726ppm. Accurately prepare 500L, 0.1 mol / L Zr doping solution: weigh 50mol (27.36kg) of Zr(SO 4 ) 4 4H 2 O powder was dissolved in 500 L of water to prepare a 0.1 mol / L doped Zr solution. The zirconium salt solution used for doping and coating is the same concentration solution.

[0078] Mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com