A double carrier fixed bed biofilm reactor

A biofilm reactor, fixed bed technology, applied in biological treatment devices, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem of periodic backwashing, etc., to overcome the clogging problem and maintain the distribution effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments. Herein, the exemplary embodiments and descriptions of the present invention are used to explain the technical solutions of the present invention, but are not intended to limit the present invention.

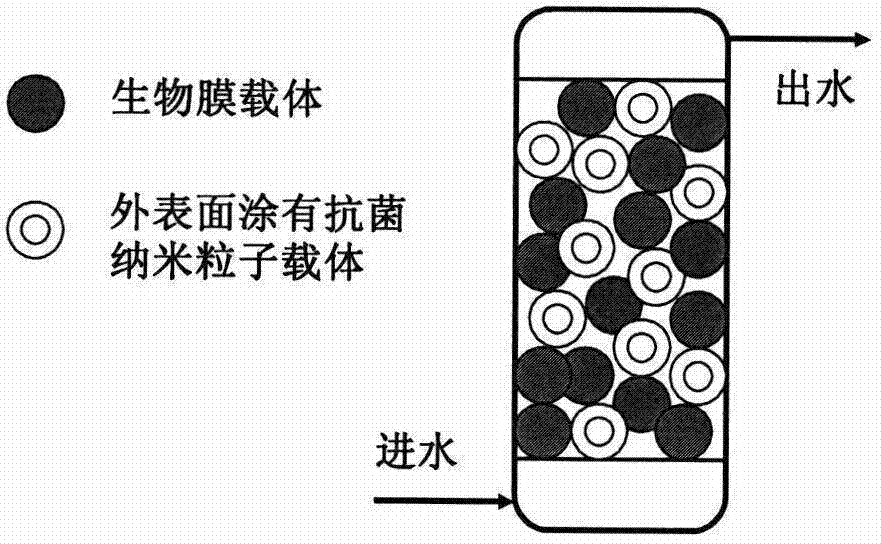

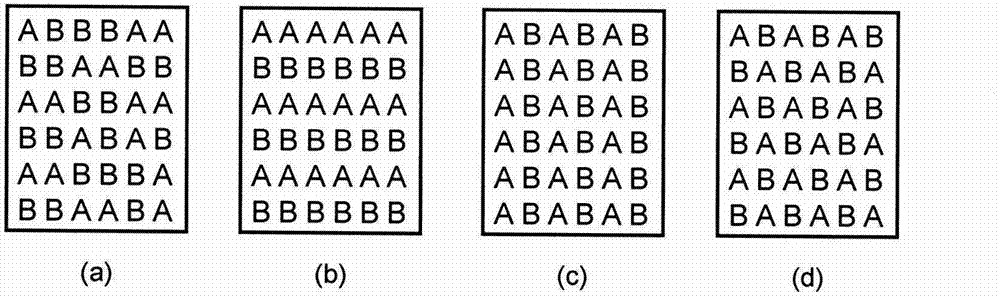

[0029] The present embodiment provides a double-carrier fixed-bed biofilm reactor, including: a reactor with a first carrier and a second carrier in the reactor; the first carrier is a biofilm carrier used for biofilm growth; The second carrier is an antibacterial carrier whose outer surface is coated with antibacterial silver nanoparticles; the second carrier is distributed between the first carriers; the reactor is one of aerobic or anaerobic reactors; The material of the first carrier and the second carrier is polyurethane foam; the antibacterial nanoparticles are antibacterial metal nanoparticles; the first carrier and the second carrier are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com