Halogen-free nano flame-retardant TPE material and preparation method thereof

A nano flame retardant and inorganic nano technology, applied in the field of halogen-free nano flame retardant TPE materials and their preparation, can solve the problems of poor dispersibility and loss of elastomer characteristics, and achieve good dispersibility, good mechanical properties, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

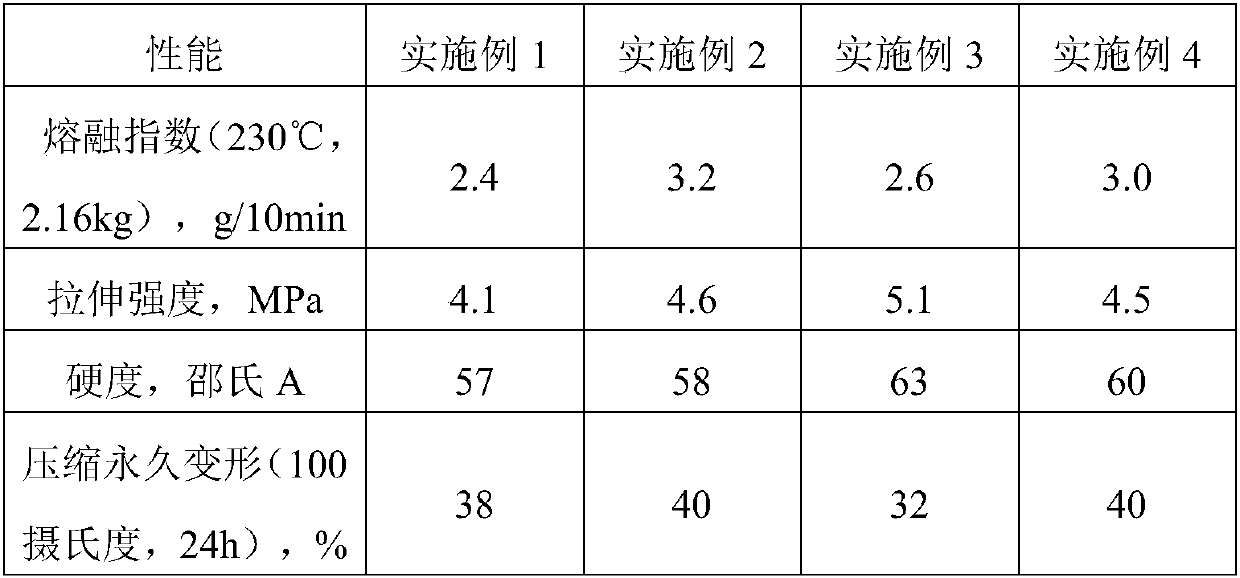

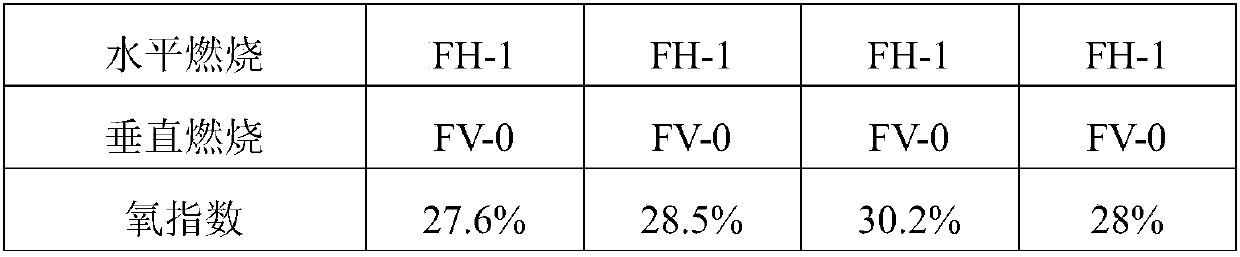

Examples

Embodiment 1

[0028] The parts by weight in the material composition used in the present embodiment and percentage are as follows:

[0029] 10 parts of styrene-ethylene-butadiene-styrene (SEBS), 20 parts of extender oil (paraffin oil), 5 parts of flame retardant synergist (red phosphorus), 15 parts of polypropylene, inorganic nano-magnesium hydroxide filler 50 parts of material, wherein, each part of inorganic nano-magnesium hydroxide filler masterbatch contains 0.5 part of styrene-butadiene copolymer (K resin) and 0.5 part of surface-modified inorganic magnesium hydroxide.

[0030] A preparation method of halogen-free nano flame-retardant TPE material, it comprises the following steps:

[0031] 1) Inorganic hydroxide surface modification

[0032] Add the silane coupling agent diluted with acetone in the nano inorganic magnesium hydroxide, the silane coupling agent is gamma-mercaptopropyltrioxymethylsilane (A-189), wherein the volume ratio of acetone and silane coupling agent is 3:1, mi...

Embodiment 2

[0040] The parts by weight in the material composition used in the present embodiment and percentage are as follows:

[0041] 30 parts of styrene-butadiene-styrene (SBS), 40 parts of extender oil (naphthenic oil), 1 part of flame retardant synergist (expandable graphite), 9 parts of polypropylene, inorganic aluminum hydroxide filler masterbatch 20 parts, wherein, each part of inorganic nano-aluminum hydroxide filler masterbatch contains 0.2 part of polystyrene (PS) and 0.8 part of surface-modified inorganic aluminum hydroxide.

[0042] A preparation method of halogen-free nano flame-retardant TPE material, it comprises the following steps:

[0043] 1) Inorganic hydroxide surface modification

[0044] Add the silane coupling agent diluted with acetone in the nano inorganic aluminum hydroxide, the silane coupling agent is bis-[g-(triethoxy silicon) propyl group]-tetrasulfide (silicon 69), wherein acetone and silane The volume ratio of the coupling agent is 3:1, mixed in the mi...

Embodiment 3

[0052] The material composition used in the present embodiment and the parts by weight in the percentage are as follows:

[0053] Styrene-ethylene-butadiene-styrene (SEBS) 25 parts, filler oil (paraffin oil) 30 parts, flame retardant synergist (red phosphorus) 3 parts, polypropylene 2 parts, inorganic magnesium hydroxide filler masterbatch 40 parts, wherein each part of inorganic nanometer magnesium hydroxide filling masterbatch contains 0.6 part of styrene-butadiene copolymer (K resin) and 0.4 part of surface-modified inorganic magnesium hydroxide.

[0054] A preparation method of halogen-free nano flame retardant TPE material, which comprises the following steps:

[0055] 1) Surface modification of inorganic hydroxide

[0056] A silane coupling agent diluted with acetone was added to the nano inorganic magnesium hydroxide. The silane coupling agent was γ-thiopropyltrioxymethylsilane (A-189), and the volume ratio of acetone to the silane coupling agent was 3:1, mix in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com