Middle-sole latex and preparation process thereof

A preparation process, latex technology, applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of not easy to degrade, easy to regain moisture, difficult to degrade paper molds, etc., to achieve the effect of easy recycling, good affinity and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

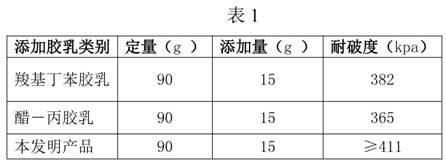

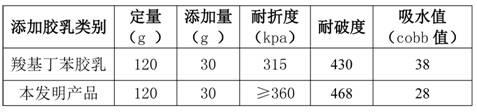

Examples

Embodiment 1

[0054] A shoe midsole latex, the raw material of which contains the following parts by mass: 0.5 parts of modified starch, 1 part of cellulose, 15 parts of butyl acrylate, 5 parts of isooctyl acrylate, 32 parts of styrene, 3 parts of functional monomer, emulsified 2.5 parts of an agent and 0.5 parts of an initiator, wherein the functional monomer is acrylamide, the emulsifier is disodium phosphate half ester ethoxylated alcohol, and the initiator is potassium persulfate.

[0055] Its preparation process is as follows:

[0056]1) Add modified starch, cellulose and appropriate amount of water into the reaction kettle, gradually raise the temperature to 75°C under stirring, keep it warm for 40 minutes, and then adjust the temperature to 80°C;

[0057] 2) Mix butyl acrylate, isooctyl acrylate, styrene, and functional monomers evenly to obtain an ethylenic monomer mixture, which is set aside;

[0058] 3) Continue to add emulsifier and 0.5% of pH buffering agent to the reaction ket...

Embodiment 2

[0061] A shoe midsole latex, the raw material of which contains the following parts by mass: 1 part of modified starch, 0.8 part of cellulose, 17 parts of butyl acrylate, 4 parts of isooctyl acrylate, 34 parts of styrene, 1 part of functional monomer, emulsified 3 parts of agent and 0.4 part of initiator, wherein, the functional monomer is styrene, the emulsifier is the equal proportion mixture of E010 and disodium ethoxylate phosphate half ester, and the initiator is potassium persulfate, sodium bisulfite and Equal proportion mixture of AIBA.

[0062] Its preparation process is as follows:

[0063] 1) Add modified starch, cellulose and appropriate amount of water to the reactor, gradually raise the temperature to 90°C under stirring, keep it warm for 40 minutes, and then adjust the temperature to 75°C;

[0064] 2) Mix butyl acrylate, isooctyl acrylate, styrene, and functional monomers evenly to obtain an ethylenic monomer mixture, which is set aside;

[0065] 3) Continue to...

Embodiment 3

[0068] A shoe midsole latex, the raw material of which contains the following parts by mass: 2 parts of modified starch, 0.5 part of cellulose, 20 parts of butyl acrylate, 6 parts of isooctyl acrylate, 28 parts of styrene, 4 parts of functional monomer, emulsified 2.5-4 parts of agent and 0.2-0.8 parts of initiator, the functional monomer is methacrylic acid, the emulsifier is an equal proportion mixture of E010 and modified fatty alcohol ethoxylate, and the initiator is potassium persulfate and bisulfite Sodium mixture in equal proportions.

[0069] Its preparation process comprises the following steps:

[0070] 1) Add appropriate amount of water, modified starch, cellulose, part of emulsifier and part of pH buffer into the reaction kettle, and stir evenly;

[0071] 2) Add water and the remaining emulsifier into the emulsification kettle, and continue to drop butyl acrylate, isooctyl acrylate, styrene, and functional monomers under stirring, and stir evenly;

[0072] 3) Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com