Molding resin for improving insulation performance and heat deformation temperature of outdoor electrical appliance, and preparation method thereof

A heat distortion temperature and insulation performance technology, applied in the chemical industry, can solve the problems of low tensile strength, bending strength and low hardness, and achieve the effect of improving Barcol hardness and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also discloses a method for preparing a molded resin for improving the insulation performance and thermal deformation temperature of outdoor electrical appliances, comprising the following steps:

[0053] Step 1, diol, phthalic anhydride, maleic anhydride, methyltetrahydrophthalic anhydride, antioxidant and 1 / 2 of the chelating agent are dropped into the reaction kettle in turn, and the temperature rise reaction is started, with the first When the rate of heating increases the temperature of the reactor from room temperature to the first temperature threshold, start stirring;

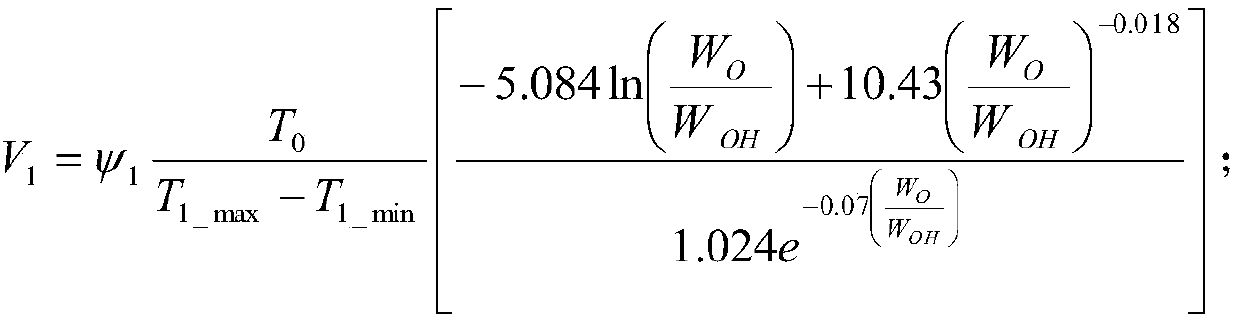

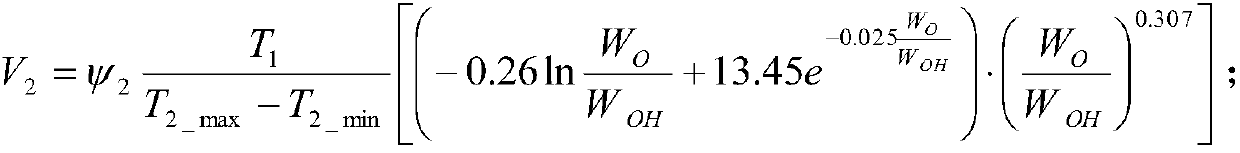

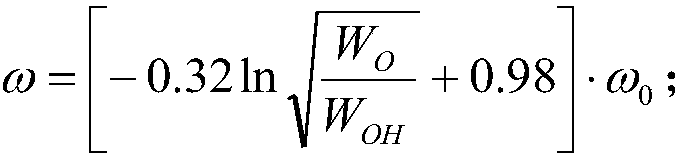

[0054] Among them, the first heating rate from room temperature to 120-140°C is:

[0055]

[0056] where, ψ 1 is the first heating coefficient, T 0 is room temperature, T 1_max is the maximum temperature of the first temperature threshold, T 1_min is the minimum temperature of the first temperature threshold, W O is the total mass fraction of acid anhydride, W OH Be...

Embodiment 1

[0072] The raw materials and mass parts thereof for preparing molding resin are as follows:

[0073] Step 1, 28.5 parts of a mixture of 1,2-ethanediol, 1,3-propanediol and 1,4-butanediol with a mass ratio of 1.5:8.5:1, 3 parts of phthalic anhydride, 26.5 parts of maleic anhydride part, 4 parts of methyltetrahydrophthalic anhydride, 23 parts of styrene, 0.07 part of polymerization inhibitor, 0.08 part of retarder, 0.08 part of antioxidant, 0.18 part of plasticizer, 7 parts of chelating agent;

[0074] A mixture of 1,2-ethanediol, 1,3-propanediol and 1,4-butanediol with a mass ratio of 1.5:8.5:1, phthalic anhydride, maleic anhydride, methyltetrahydrophthalic anhydride Diformic anhydride, the mixture of antioxidant 1010 and antioxidant 1076 with a mass ratio of 1.5:1, and 1 / 2 of 1,3-diketone are put into the reactor in turn, and the temperature rise reaction is started, and the reactor is heated at the first heating rate. When the temperature rises from room temperature to 120-1...

Embodiment 2

[0086] Step 1. Prepare the raw materials and parts by mass for preparing the molded resin as follows:

[0087] 37.5 parts of a mixture of 1,2-ethanediol, 1,3-propanediol and 1,4-butanediol with a mass ratio of 3.5:4.5:1, 4.5 parts of phthalic anhydride, 21.5 parts of maleic anhydride, 8.5 parts of tetrahydrophthalic anhydride, 28 parts of styrene, 0.13 parts of polymerization inhibitor, 0.41 part of retarder, 0.11 parts of the mixture of antioxidant 1010 and antioxidant 1076 with a mass ratio of 3.5:1, plasticizer 0.35 parts, 15 parts of chelating agent;

[0088] A mixture of 1,2-ethanediol, 1,3-propanediol and 1,4-butanediol with a mass ratio of 3.5:4.5:1, phthalic anhydride, maleic anhydride, methyltetrahydrophthalic anhydride Diformic anhydride, the mixture of antioxidant 1010 and antioxidant 1076 with a mass ratio of 3.5:1, and 1 / 2 of 1,3-diketone are put into the reactor in turn, and the temperature rise reaction is started, and the reactor is heated at the first heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com