Low-temperature power battery based on conductive adhesive and preparation method and application of conductive adhesive

A technology of conductive adhesive and conductive adhesive layer, applied in the field of conductive adhesive, can solve the problems of local agglomeration, affecting the conductive properties of finished materials, and high price, and achieve the effects of improving mechanical strength, electrical conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

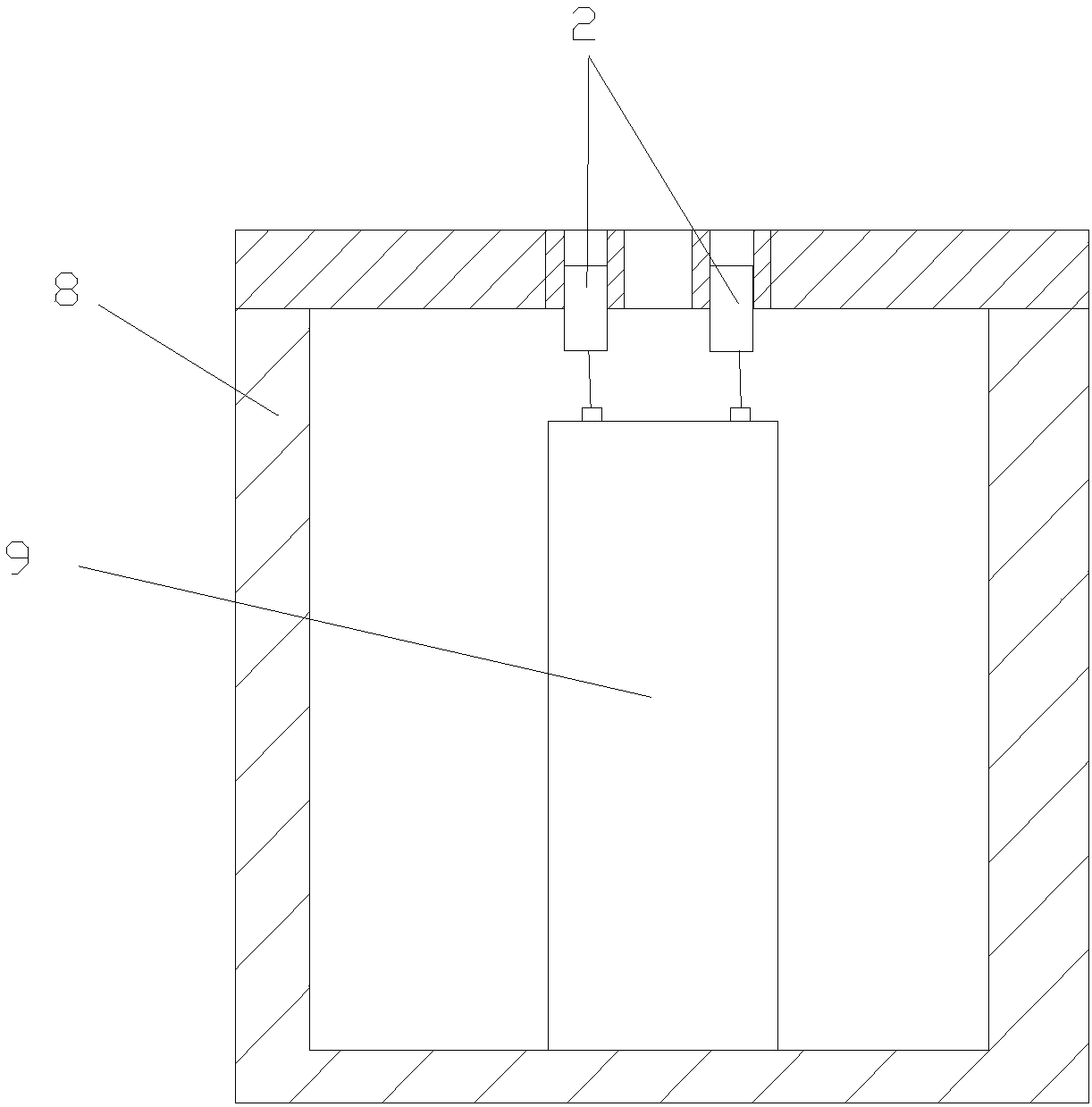

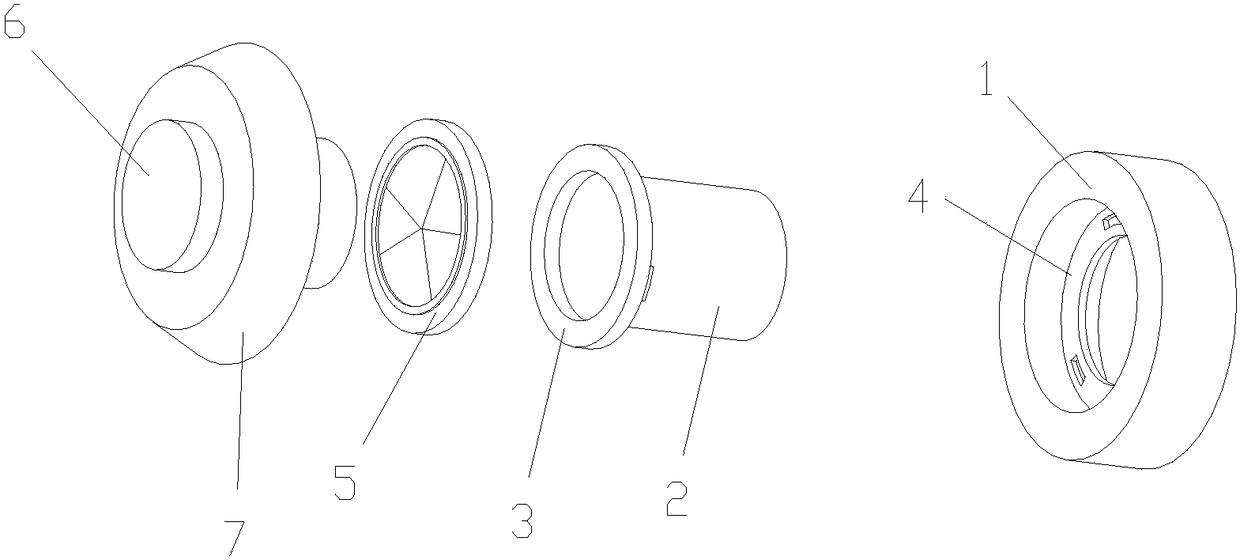

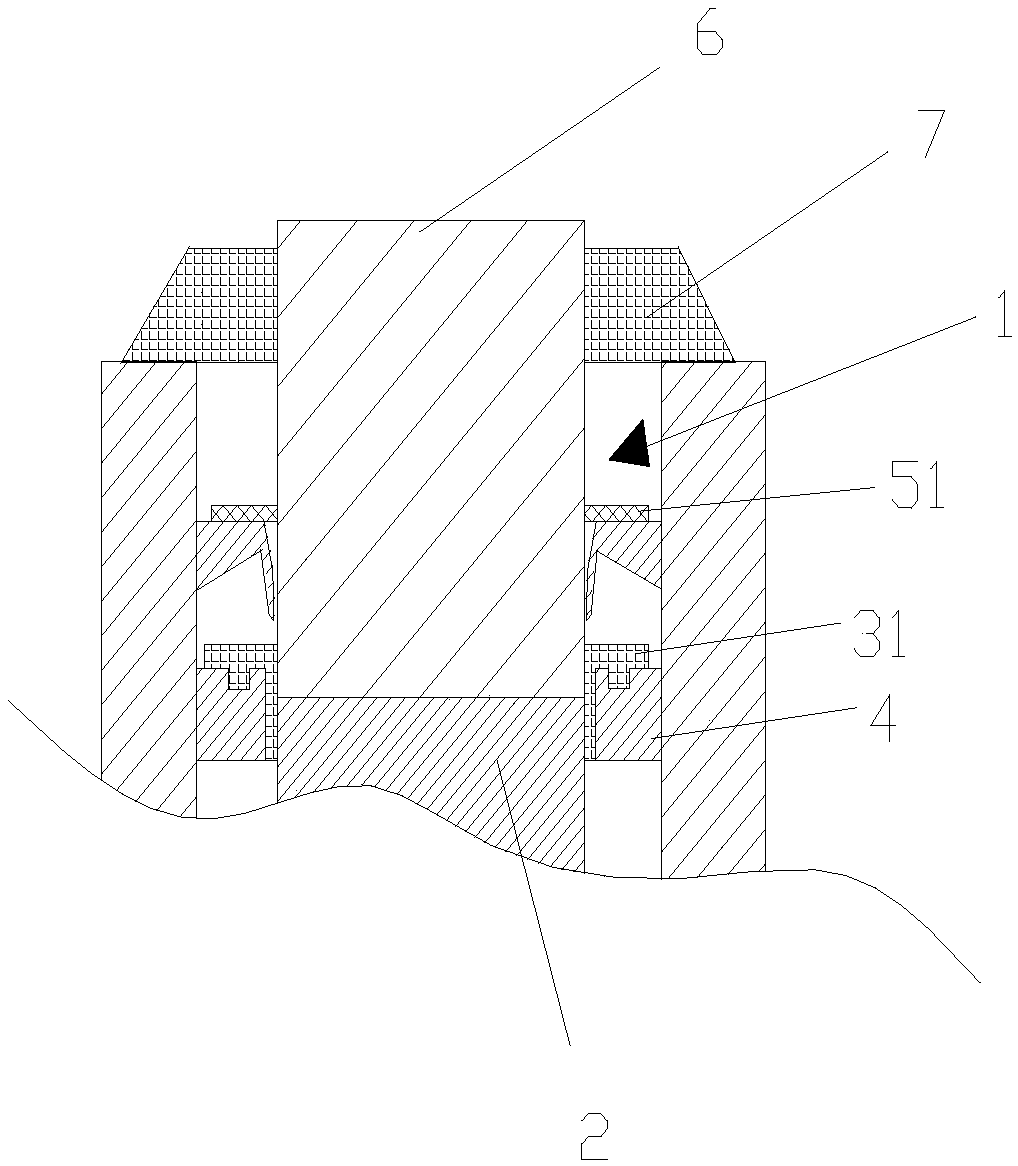

[0041] This embodiment discloses a low-temperature power battery based on conductive glue, including a low-temperature power battery body based on conductive glue, the positive terminal and the negative terminal located on both ends of the battery body, and the positive terminal or the negative terminal or at the Both the positive end and the negative end are provided with conductive glue.

Embodiment 2

[0043] This embodiment discloses a preparation method of conductive adhesive, comprising the following steps:

[0044] Step 1. Put the plants containing lignin in the NaOH aqueous solution with a mass concentration of 10g / L according to the ratio of material to liquid 1:50, heat to 70°C, soak for 13h, rinse, and dry in an oven at 40°C. Then grind into powder; mix the powder with deionized water at a mass ratio of 1:8, then add 5FPU / g cellulase preparation, hydrolyze at 50°C for 1.5h, boil for 5min, filter and wash, Obtain lignin fiber particles;

[0045] Step 2: Mix silver nitrate, ammonia water and polyvinylpyrrolidone, add lignin fiber particles, mix well, pass nitrogen gas to remove oxygen in the solution, add sodium borohydride to react for 80min under nitrogen protection, temperature 50°C, centrifuge, Precipitate, wash to no silver ion, vacuum dry, pulverize, obtain lignin fiber particle modified silver powder; Wherein, the mol ratio of silver nitrate and ammoniacal liqu...

Embodiment 3

[0048] This embodiment discloses a preparation method of conductive adhesive, comprising the following steps:

[0049] Step 1. Put lignin-containing plants into NaOH aqueous solution with a mass concentration of 12g / L according to the ratio of material to liquid 1:100, heat to 95°C, soak for 2h, rinse, and dry in an oven at 30°C. Grind it into powder again; mix the powder with deionized water at a mass ratio of 3:5, then add 8 FPU / g cellulase preparation, hydrolyze at 50°C for 2 hours, boil and inactivate for 10 minutes, and filter and wash to obtain lignin fiber particles;

[0050] Step 2: Mix silver nitrate, ammonia water and polyvinylpyrrolidone, add lignin fiber particles, mix well, pass nitrogen gas to remove oxygen in the solution, add sodium borohydride to react for 50 minutes under nitrogen protection, temperature 60°C, centrifuge, Precipitate, wash to no silver ion, vacuum dry, pulverize, obtain lignin fiber particle modified silver powder; Wherein, the mol ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com