Preparation method for improving conductivity of composite epoxy resin matrix

An epoxy resin matrix and composite material technology, applied in the field of composite materials, can solve the problems of increasing aircraft mass, expensive carbon nanotubes, increased cost, etc., and achieves high performance and is conducive to wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

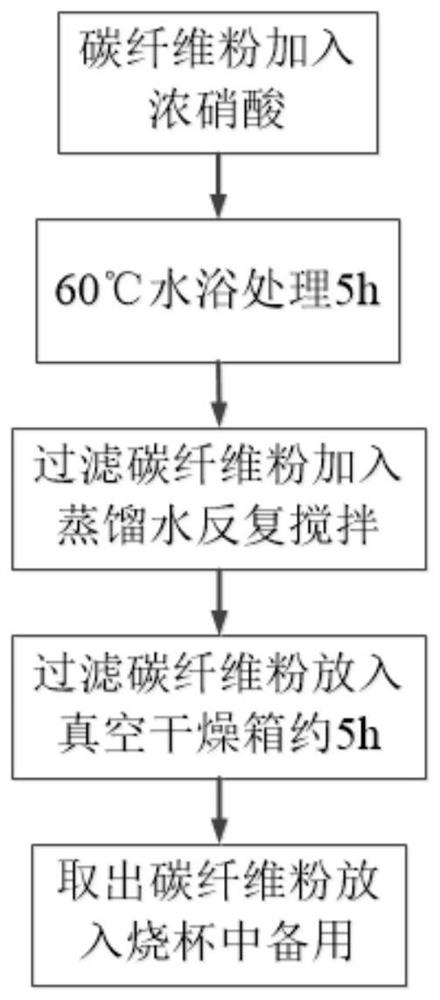

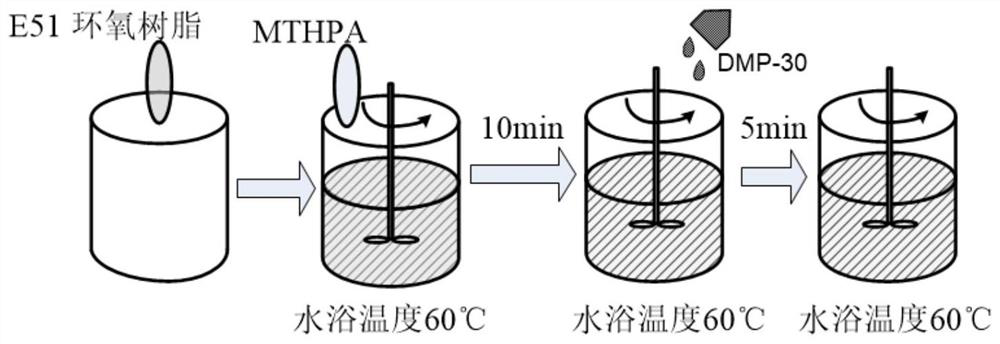

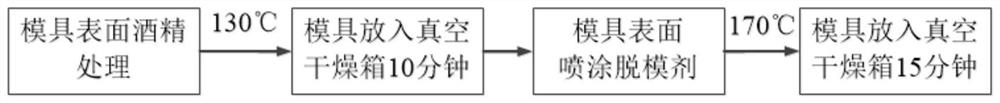

[0023] Embodiment 1: the preparation method of improving the electrical conductivity of the composite material epoxy resin matrix specifically comprises the following steps:

[0024] S1 preliminary preparation: Weigh carbon fiber powder, epoxy resin, methyltetrahydrophthalic anhydride curing agent, DMP-30 accelerator and nitric acid in proportion; the carbon fiber powder, epoxy resin, methyltetrahydrophthalic anhydride The mass parts of diformic anhydride curing agent, DMP-30 accelerator and nitric acid are: 17.6 parts of carbon fiber powder, 44.1 parts of epoxy resin, 37.4 parts of methyltetrahydrophthalic anhydride curing agent, 0.9 parts of DMP-30 accelerator parts, 50 parts of nitric acid; wherein the carbon content in the carbon fiber powder is greater than 95%, and the particle diameter is less than 8 μm; the concentration of the nitric acid is 60%; wherein the model of the carbon fiber powder is T700, the density is 1.76, and the epoxy resin The model is Yueyang Petroch...

Embodiment 2

[0029] Embodiment 2: the preparation method of improving the conductivity of the epoxy resin matrix of the composite material specifically comprises the following steps:

[0030] S1 preliminary preparation: Weigh carbon fiber powder, epoxy resin, methyltetrahydrophthalic anhydride curing agent, DMP-30 accelerator and nitric acid in proportion; the carbon fiber powder, epoxy resin, methyltetrahydrophthalic anhydride The mass parts of dimethyl tetrahydrophthalic anhydride curing agent, DMP-30 accelerator and nitric acid are: 15 parts of carbon fiber powder, 40 parts of epoxy resin, 30 parts of methyl tetrahydrophthalic anhydride curing agent, 0.5 parts of DMP-30 accelerator parts, 42.6 parts of nitric acid; wherein the carbon content in the carbon fiber powder is greater than 95%, and the particle diameter is less than 8 μm; the concentration of the nitric acid is 60%; wherein the model of the carbon fiber powder is T700, the density is 1.76, and the epoxy resin The model is Yue...

Embodiment 3

[0035] Embodiment 3: the preparation method for improving the electrical conductivity of the composite epoxy resin matrix specifically comprises the following steps:

[0036] S1 preliminary preparation: Weigh carbon fiber powder, epoxy resin, methyltetrahydrophthalic anhydride curing agent, DMP-30 accelerator and nitric acid in proportion; the carbon fiber powder, epoxy resin, methyltetrahydrophthalic anhydride The mass parts of dimethyl tetrahydrophthalic anhydride curing agent, DMP-30 accelerator and nitric acid are: 20 parts of carbon fiber powder, 50 parts of epoxy resin, 40 parts of methyl tetrahydrophthalic anhydride curing agent, 1.5 parts of DMP-30 accelerator parts, 56.8 parts of nitric acid; wherein the carbon content in the carbon fiber powder is greater than 95%, and the particle diameter is less than 8 μm; the concentration of the nitric acid is 60%; wherein the model of the carbon fiber powder is T700, the density is 1.76, and the epoxy resin The model is Yueyang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com