Environment-friendly insulating material

An insulating material and environmentally friendly technology, applied in the field of insulating materials, can solve problems such as uneven properties, large thermal conductivity, and unstable dimensions, and achieve the effect of avoiding uneven properties and reducing sedimentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

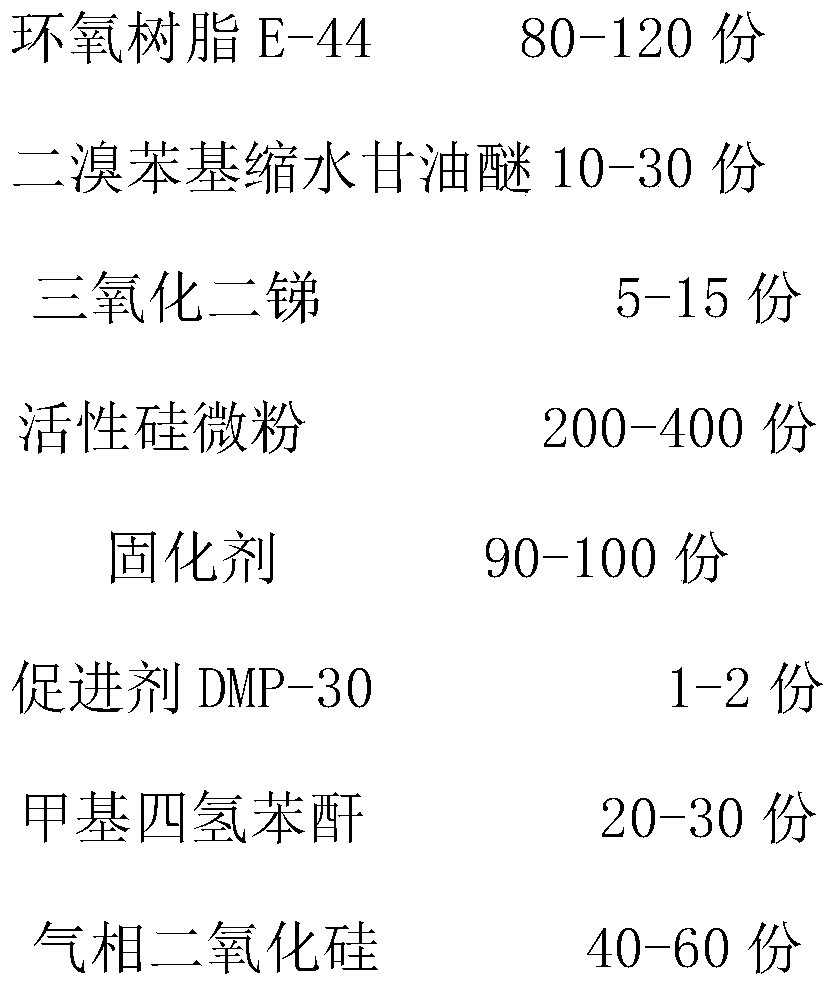

[0021] An environmentally friendly insulating material, which comprises the following components in parts by weight:

[0022]

[0023] The particle size of the active silica powder is 2 μm.

[0024] A production process of an environmentally friendly insulating material, the process comprises the following steps:

[0025] S1: Dry the active silica powder with a dryer to control its moisture content to less than 0.4%;

[0026] S2: Prepare two components in the following order:

[0027] Component A: epoxy resin, accelerator DMP-30, methyltetrahydrophthalic anhydride, fumed silica, antimony trioxide and silicon micropowder;

[0028] B component: curing agent, dibromophenyl glycidyl ether, methyl tetrahydrophthalic anhydride, fumed silica and silicon micropowder;

[0029] S3: Heating component A to 85°C, degassing and stirring under vacuum conditions, stirring speed 200r / min, time 20min, heating component B to 40°C, degassing and stirring under vacuum conditions, stirring S...

Embodiment 2

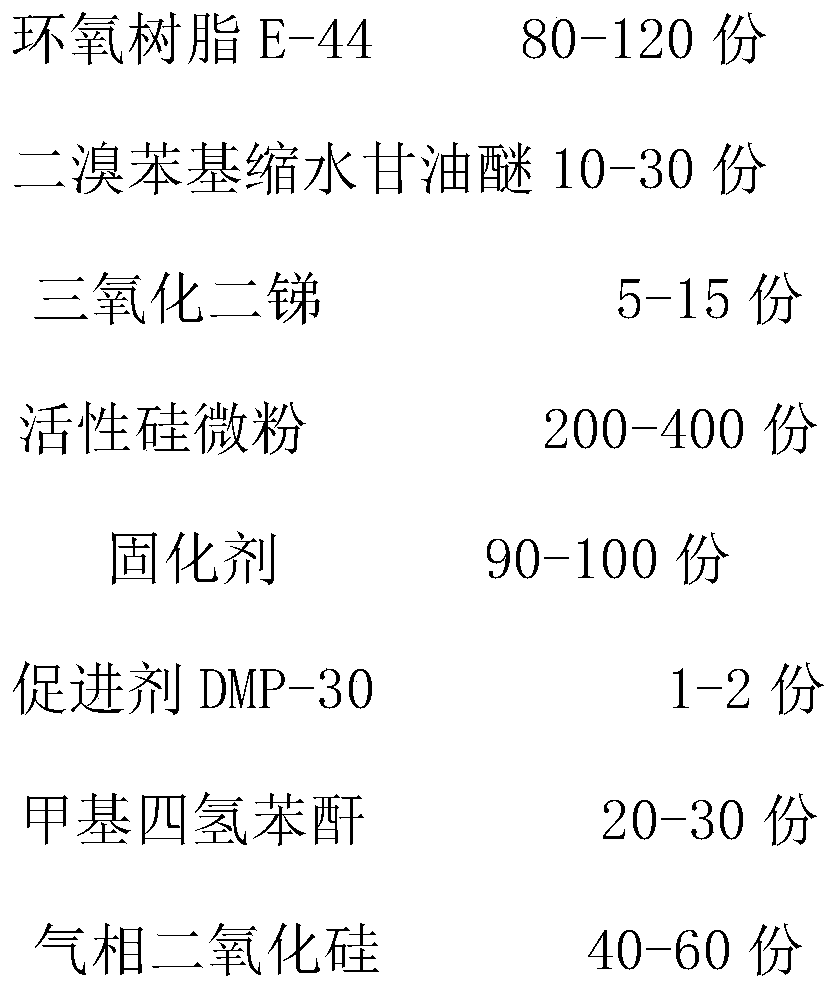

[0035] An environmentally friendly insulating material, which comprises the following components in parts by weight:

[0036]

[0037] The particle size of the active silica powder is 61 μm.

[0038] A production process of an environmentally friendly insulating material, the process comprises the following steps:

[0039] S1: Dry the active silica powder with a dryer to control its moisture content to less than 0.4%;

[0040] S2: Prepare two components in the following order:

[0041] Component A: epoxy resin, accelerator DMP-30, methyltetrahydrophthalic anhydride, fumed silica, antimony trioxide and silicon micropowder;

[0042] B component: curing agent, dibromophenyl glycidyl ether, methyl tetrahydrophthalic anhydride, fumed silica and silicon micropowder;

[0043] S3: Heating component A to 90°C, degassing and stirring under vacuum conditions, stirring speed 250r / min, time 30min, heating component B to 50°C, degassing and stirring under vacuum conditions, stirring ...

Embodiment 3

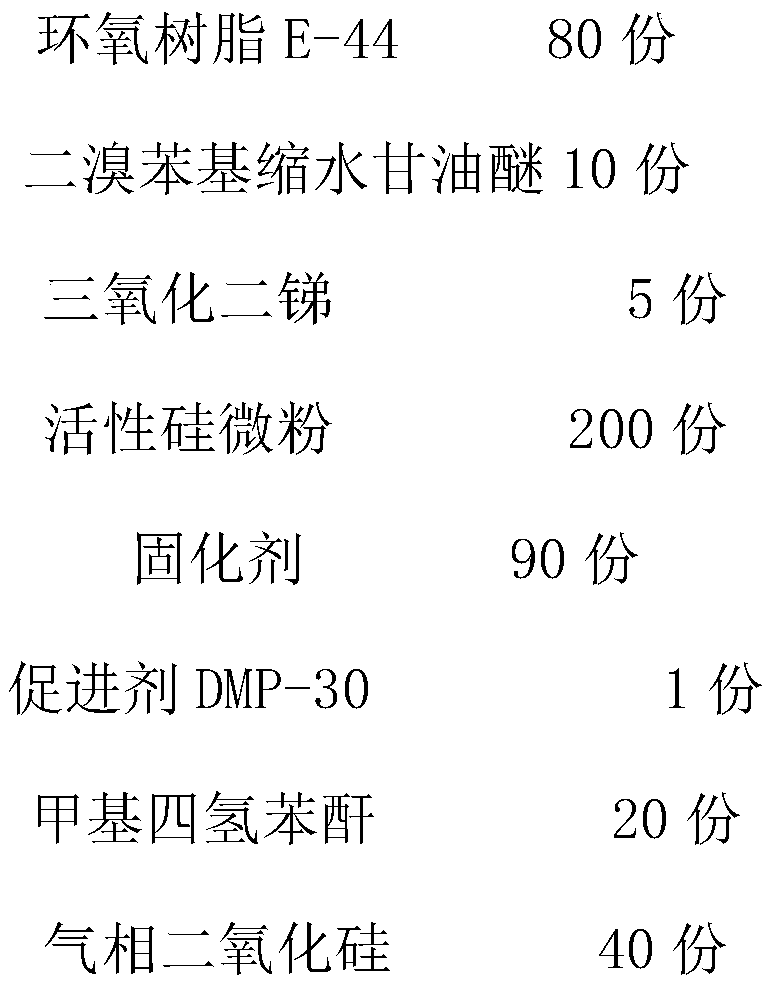

[0049] An environmentally friendly insulating material, which comprises the following components in parts by weight:

[0050]

[0051]

[0052] The particle size of the active silica powder is 120 μm.

[0053] A production process of an environmentally friendly insulating material, the process comprises the following steps:

[0054] S1: Dry the active silica powder with a dryer to control its moisture content to less than 0.4%;

[0055] S2: Prepare two components in the following order:

[0056] Component A: epoxy resin, accelerator DMP-30, methyltetrahydrophthalic anhydride, fumed silica, antimony trioxide and silicon micropowder;

[0057] B component: curing agent, dibromophenyl glycidyl ether, methyl tetrahydrophthalic anhydride, fumed silica and silicon micropowder;

[0058] S3: Heating component A to 95°C, degassing and stirring under vacuum conditions, stirring speed 300r / min, time 40min, heating component B to 60°C, degassing and stirring under vacuum condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com