Condensation recovery process of pentadiene in production of methyl tetrahydrophthalic anhydride

A methyltetrahydrophthalic anhydride, condensation recovery technology, applied in the direction of hydrocarbons, hydrocarbon purification/separation, chemical instruments and methods, etc., can solve the problem that the boiling point of pentadiene is low enough to recover pentadiene , waste of pentadiene raw materials and other issues, to achieve the effects of low content of harmful substances, increase energy utilization rate, and protect the environment

Inactive Publication Date: 2019-01-04

嘉兴南洋万事兴化工有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The above-mentioned prior art scheme has the following defects: due to the low boiling point of pentadiene, it is not enough to recover most of the pentadiene through the above-mentioned condensation operation, and a considerable part of pentadiene exists in the tail gas, resulting in the production of pentadiene raw materials. waste of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

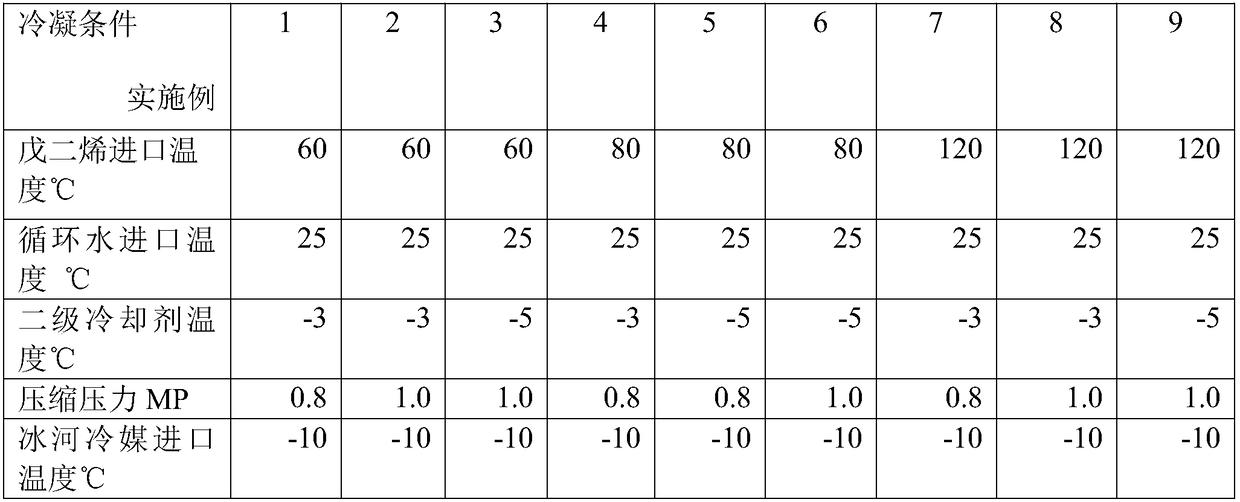

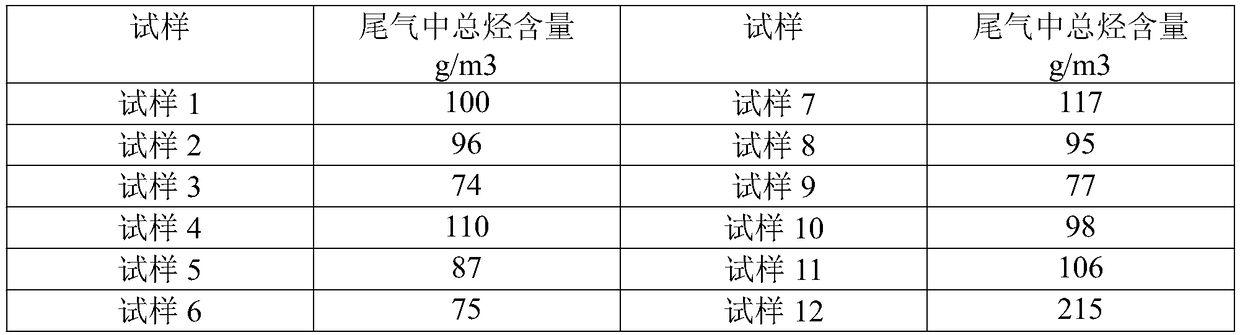

Embodiment 1

[0042] Embodiment 10, a pentadiene condensation recovery process in the production of methyltetrahydrophthalic anhydride, differs from Example 1 in that the coolant is ethylene glycol C 2 h 6 o 2 .

Embodiment 11

[0043] Example 11, a pentadiene condensation recovery process in the production of methyltetrahydrophthalic anhydride, differs from Example 1 in that the alcohol or salt coolant is magnesium chloride MgCl 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

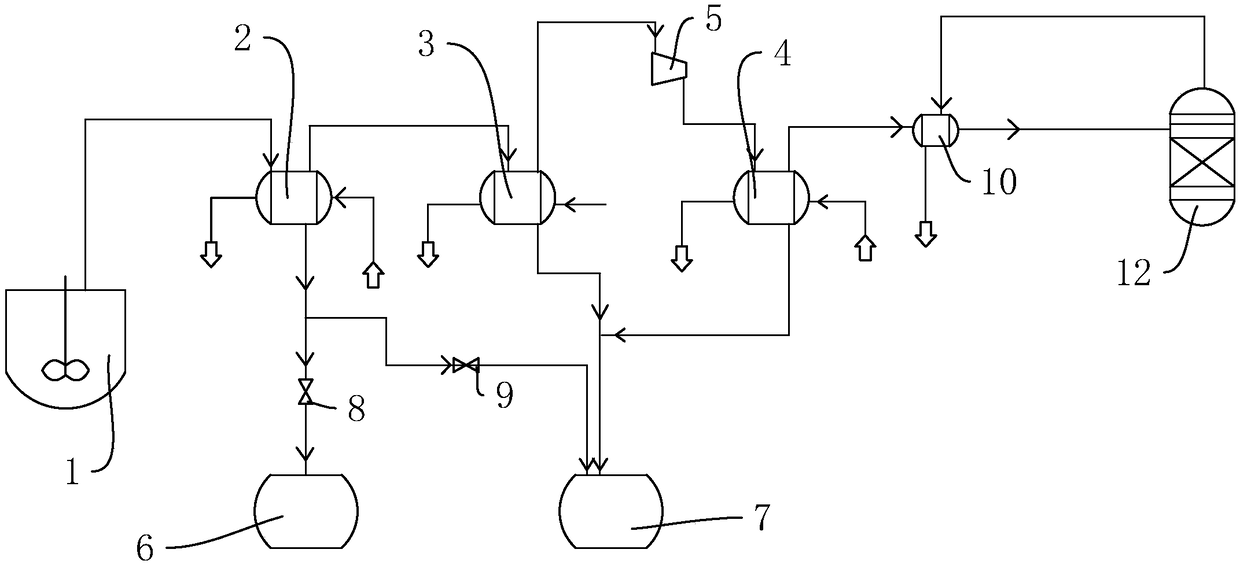

The invention relates to a condensation recovery process of pentadiene in the production of methyl tetrahydrophthalic anhydride, and belongs to the technical field of gas condensation recovery. The technical key points include: step A, pentadiene steam passes through a primary condenser, a coolant is circulating water, liquid pentadiene enters a recovery tank from the bottom of the condenser, andthe residual gas is discharged from the upper end of the condenser; step B, the residual gas enters a secondary condenser, the coolant is a salt and alcohol solution, liquid pentadiene enters the recovery tank from the bottom of the condenser, and the residual gas is discharged from the upper end of the condenser; and step C, the residual gas is pressurized and then enters a tertiary condenser, liquid pentadiene enters the recovery tank from the bottom of the condenser, and the residual gas enters a tail gas treatment device. The condensation recovery process of pentadiene in the production ofmethyl tetrahydrophthalic anhydride has the advantages of simple operation, improved pentadiene recovery rate through multistage condensation, and improved energy utilization rate through heat exchange between material flows.

Description

technical field [0001] The invention relates to the technical field of gas condensation recovery, in particular to a pentadiene condensation recovery process in the production of methyltetrahydrophthalic anhydride. Background technique [0002] At present, methyltetrahydrophthalic anhydride has the characteristics of low viscosity, stable performance, low freezing point, long pot life, low volatility, low toxicity, and good mutual solubility. Therefore, it is an indispensable new fine chemical product for electronic industry and electromechanical industry products. Widely used in potting, casting, encapsulation, lamination, molding, bonding, winding and other processes. Pentadiene is an important raw material for the production of methyltetrahydrophthalic anhydride. Pentadiene mainly comes from the coking industry. Due to the lack of oil cracking and recovery industries, the output is very small and the supply exceeds demand. [0003] The existing technology for the conde...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C11/173C07C7/04

CPCC07C7/005C07C7/04C07C11/173

Inventor 王海斌

Owner 嘉兴南洋万事兴化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com