Preparation method of high temperature resistant medical deodorization material

A deodorant material and high temperature resistant technology, applied in the field of medical materials, can solve the problems of poor light and thermal stability, inability to achieve good application stability, discoloration, etc., and achieve the effect of good performance and significant deodorization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

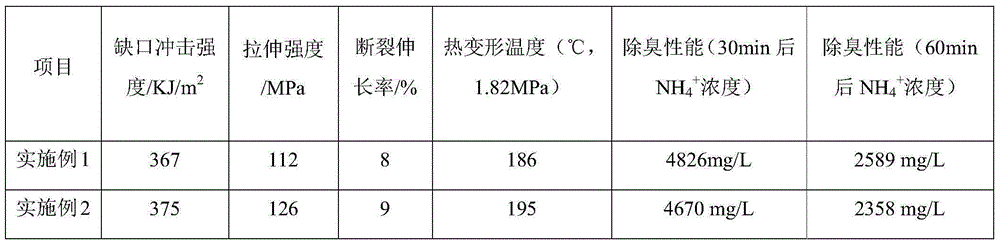

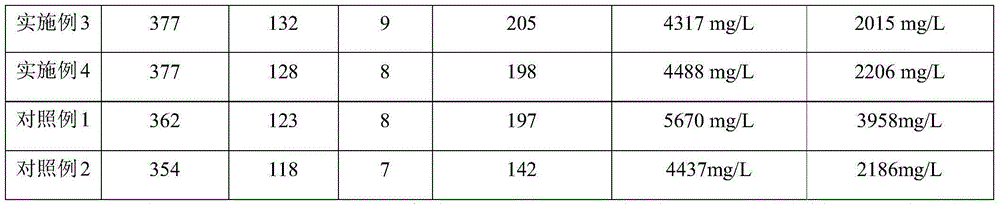

Examples

Embodiment 1

[0019] A preparation method of a high temperature resistant medical deodorant material, comprising the following preparation steps:

[0020] Step 1: Add 10 parts by weight of PVC, 2 parts of PET, 1 part of dioctyl phthalate, 0.8 part of lecithin, 3 parts of polycarbonate and 1 part of barium stearate into a mixing mixer and stir to mix evenly , the stirring speed was 160 rev / min, the stirring time was 20 minutes, and the material 1 was obtained;

[0021] Step 2: Add material 1 to the reaction kettle, add 1 part of glass fiber in parts by weight, 0.8 part of methyltetrahydrophthalic anhydride, 1 part of aluminum oxide, 2 parts of polyester fiber, 3-propane- 0.5 parts of potassium 2-alkenoyloxypropane-1-sulfonate, heated to 60°C under negative pressure of 0.01MPa, stirred for 2 hours, then heated to 90°C under normal pressure, stirred for 30 minutes , down to 0°C at a cooling rate of 20°C / min, and kept at 0°C for 10 minutes to obtain material 2;

[0022] Step 3, drying the mat...

Embodiment 2

[0026] A preparation method of a high temperature resistant medical deodorant material, comprising the following preparation steps:

[0027] Step 1: Add 13 parts of PVC in parts by weight, 3 parts of PET, 2 parts of dioctyl phthalate, 1 part of lecithin, 4 parts of polycarbonate and 2 parts of barium stearate into a mixing mixer and stir to mix evenly , the stirring speed was 165 rev / min, the stirring time was 23 minutes, and the material 1 was obtained;

[0028] Step 2: Add material 1 to the reactor, add 2 parts by weight of glass fiber, 1 part of methyltetrahydrophthalic anhydride, 2 parts of aluminum oxide, 3 parts of polyester fiber, 3-propane- 0.6 parts of potassium 2-alkenoyloxypropane-1-sulfonate, heated to 63°C under a negative pressure of 0.02MPa, stirred for 3 hours, then heated to 94°C under normal pressure, stirred for 36 minutes , down to 0°C at a cooling rate of 22°C / min, and kept at 0°C for 13 minutes to obtain material 2;

[0029] Step 3, drying material 2 at...

Embodiment 3

[0033] A preparation method of a high temperature resistant medical deodorant material, comprising the following preparation steps:

[0034] Step 1: Add 18 parts by weight of PVC, 5 parts of PET, 3 parts of dioctyl phthalate, 1.3 parts of lecithin, 7 parts of polycarbonate and 2 parts of barium stearate into a mixing mixer and stir to mix evenly , the stirring speed was 170 rpm, and the stirring time was 28 minutes to obtain material 1;

[0035] Step 2: Add material 1 to the reactor, add 2 parts by weight of glass fiber, 1.2 parts of methyltetrahydrophthalic anhydride, 3 parts of aluminum oxide, 4 parts of polyester fiber, 3-propane- 0.7 parts of potassium 2-alkenoyloxypropane-1-sulfonate, heated to 68°C under a negative pressure of 0.03MPa, stirred for 3 hours, then heated to 96°C under normal pressure, stirred for 45 minutes , down to 0°C at a cooling rate of 23°C / min, and kept at 0°C for 16 minutes to obtain material 2;

[0036] Step 3, drying the material 2 at a drying t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com