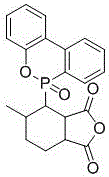

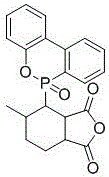

DOPO (9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) modified anhydride epoxy resin flame-retardant curing agent and preparation method thereof

A technology of acid anhydride epoxy resin and curing agent, which is applied in the field of curing agent and its preparation, can solve problems such as the limitation of the application range of flammable epoxy resin, and achieve the effects of easy control, simple preparation method and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

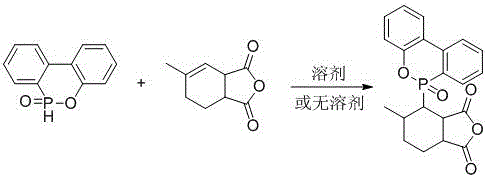

Method used

Image

Examples

Embodiment 1

[0021] Equipped with reflux condenser, thermometer, N 2 Add 160ml of dioxane as a solvent into the 250ml three-necked bottle of the introduction tube and magneton, add 86.4g of DOPO, and pass through N 2 Protect. Heat and stir until it is completely dissolved, then add 66.47g of 2-methyltetrahydrophthalic anhydride, react at reflux temperature for 12 hours, cool down to room temperature, rotary evaporate, and stand to cool to obtain a light yellow liquid.

Embodiment 2

[0023] Equipped with reflux condenser, thermometer, N 2 Add 86.4g DOPO into the 250ml three-necked bottle of the introduction tube and magnet, and inject N 2 Protect. Heat to raise the temperature, add 66.47g of 2-methyltetrahydrophthalic anhydride after it is completely melted, start stirring, react at 140°C for 6h, cool down to room temperature, and stand overnight to obtain a light yellow liquid.

Embodiment 3

[0025] Equipped with reflux condenser, thermometer, N 2 Add 160ml of toluene as a solvent to the 250ml three-necked flask that introduces the tube and magnet, add 36g of DOPO, and pass through N 2 Protect. Heat and stir until it is completely dissolved, then add 66.47g of 2-methyltetrahydrophthalic anhydride, react at reflux temperature for 8 hours, cool down to room temperature, rotary evaporate, and stand still to obtain a colorless transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com