Comprehensive furnace protecting method for steelmaking convertor furnace

A converter and furnace protection technology, applied in the direction of manufacturing converters, etc., can solve the problems of low production efficiency, unachievable, material waste, etc., and achieve the effects of consumption saving, cost saving and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] (1) The present invention mainly is divided into three big parts:

[0027] 1. Slagging furnace.

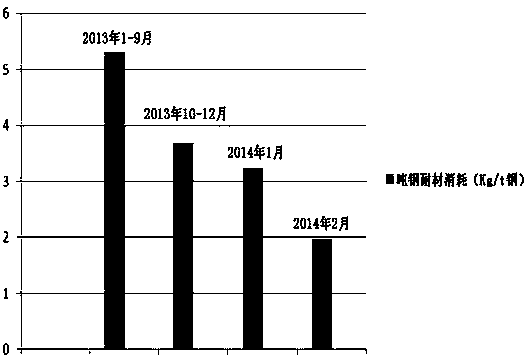

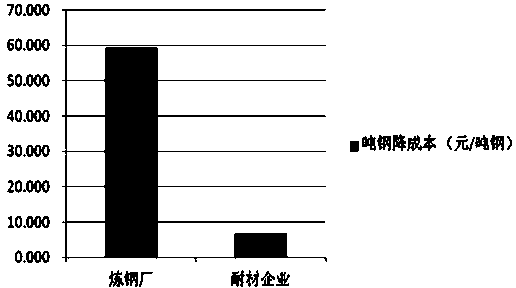

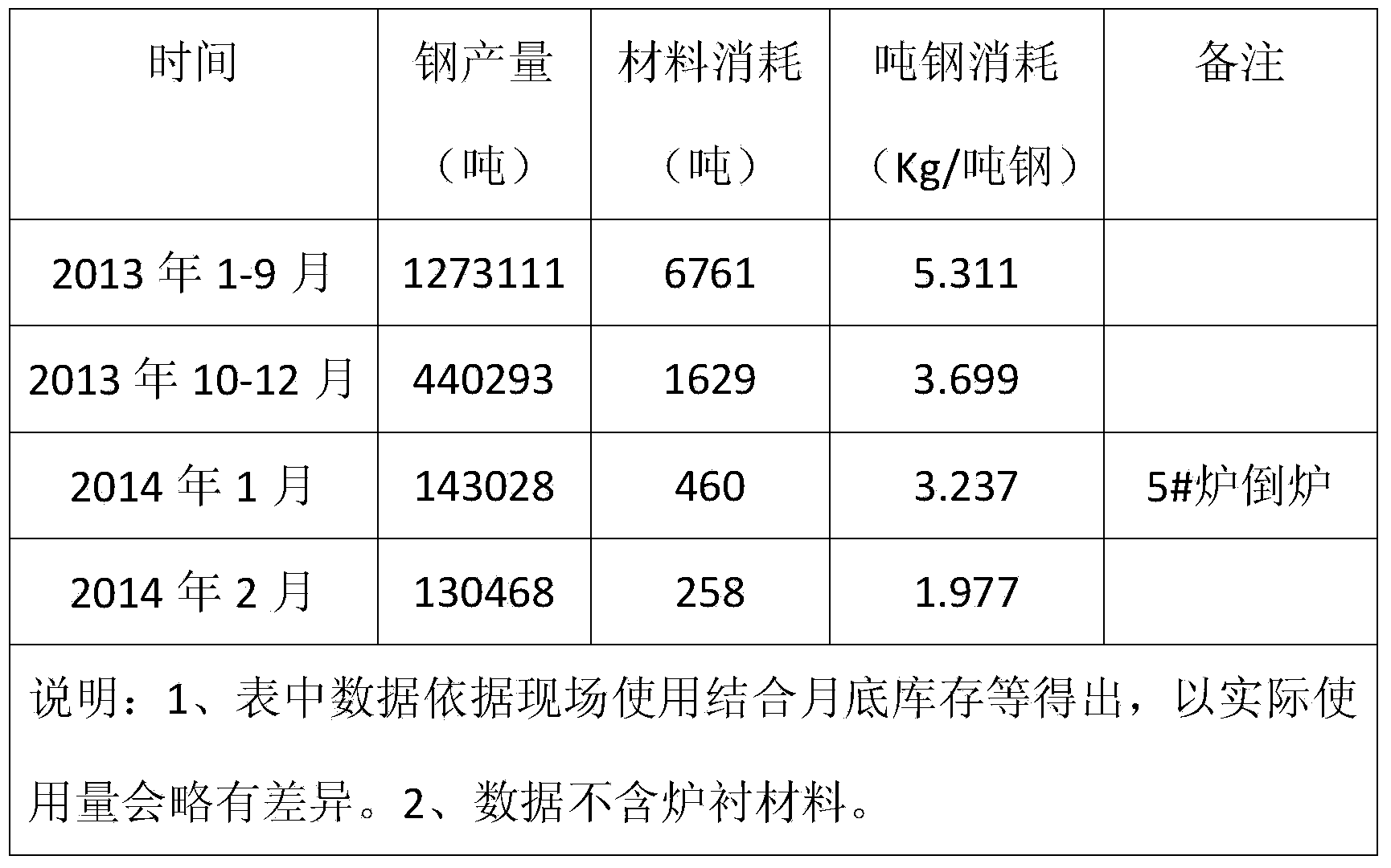

[0028] 1. Change the slag material, and the cost of slag material is lower-in the past, the slag splashing material of the converter mostly used light-burned magnesium balls and modifiers. This kind of material is not only expensive, but also has limited active ingredients, and the waste slag is large. Too much iron will increase the consumption of steel materials, which is not worth the candle! Now light-burned dolomite and raw dolomite are used as slag-splashing materials, which not only reduces the cost of slag materials by half, but also saves the cost of 26 yuan per ton of steel. Moreover, the active ingredients in dolomite account for more than 80%, and the amount of waste residue is only half of that of lightly burned magnesia balls, which is very beneficial to reducing the consumption of steel materials. At the same time, raw dolomite can also take into account th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com