Collapsible loess reinforcing grouting slurry, preparation method and application thereof

A collapsible loess and grouting technology, applied in construction, building maintenance, building construction, etc., can solve the problems of uneven mixing of carbon dioxide and water glass, weaken the foundation reinforcement effect, affect the reinforcement effect, etc., and achieve good low temperature resistance. , good wear resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

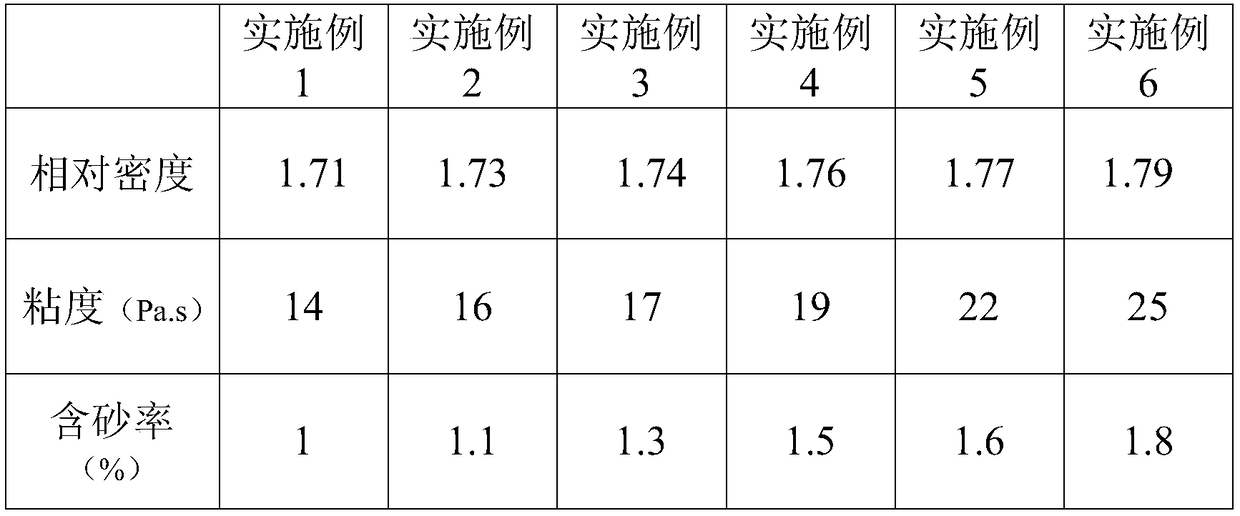

Examples

Embodiment 1

[0020] A collapsible loess reinforcement grout, comprising the following components by weight ratio: 30 parts of Portland cement, 160 parts of fine aggregate, 80 parts of cementitious material, 15 parts of bentonite, 5 parts of paraffin, and 10 parts of magnetic powder , 2 parts of external admixture, 35 parts of water, the density of the above components after mixing is 2100kg / m 3 .

[0021] Among them, the fine aggregate is natural sand. The magnetic powder is manganese zinc ferrite powder, the external dopant is sodium hydroxide and sodium chloride, and the cementitious material is fly ash.

[0022] The preparation method of the collapsible loess reinforcement grouting slurry comprises the following steps:

[0023] Step 1: Weigh according to the above group distribution ratio;

[0024] Step 2: Mix the magnetic particles, the external admixture and an appropriate amount of water with each other, stir evenly, and make a mixed solution for later use;

[0025] Step 3: Add b...

Embodiment 2

[0028] A collapsible loess reinforcement grouting slurry with magnetically sensitive thickening effect comprises the following components according to the weight ratio:

[0029] 32 parts of ordinary Portland cement, 168 parts of fine aggregate, 85 parts of cementitious material, 16 parts of bentonite, 7 parts of paraffin, 11 parts of magnetic powder, 4 parts of external admixture, 37 parts of water, and the mixing material of the above components The final density is 2250kg / m 3 .

[0030] Among them, the fine aggregate is artificial sand. The magnetic powder is manganese zinc ferrite powder, the external dopant is potassium hydroxide and calcium chloride solution, and the cementitious material is fly ash.

[0031] The preparation method and application of the collapsible loess reinforcement grouting slurry with magnetically sensitive thickening effect are the same as those in Example 1.

Embodiment 3

[0033] A collapsible loess reinforcement grouting slurry with magnetically sensitive thickening effect comprises the following components according to the weight ratio:

[0034] 34 parts of ordinary Portland cement, 175 parts of fine aggregate, 89 parts of cementitious material, 17 parts of bentonite, 9 parts of paraffin, 12 parts of magnetic powder, 3 parts of external admixture, 40 parts of water, after mixing the above components The density is 2400kg / m 3 .

[0035] Among them, the fine aggregate is natural sand. The magnetic powder is manganese zinc ferrite powder, the external dopant is calcium hydroxide and sodium chloride solution, and the cementitious material is fly ash.

[0036] The preparation method and application of the collapsible loess reinforcement grouting slurry with magnetically sensitive thickening effect are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com