Low-refractive optical fiber coating resin

A low-refractive-index, resin-coated technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as hindering the development of special optical fibers in China, small specifications, and high prices, and avoid a significant increase in the resin's refractive index. , not easy to break, improve the effect of curing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

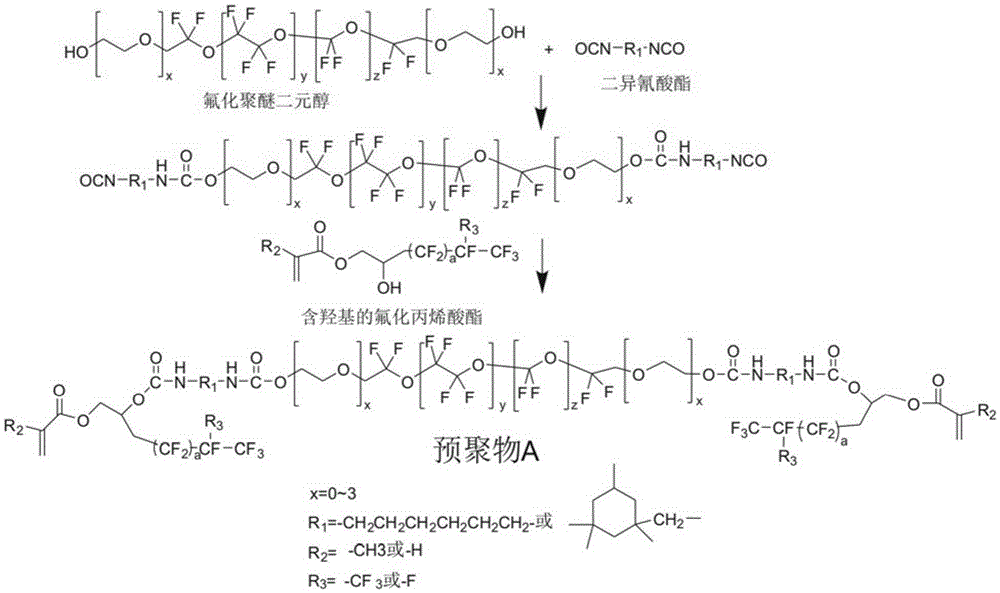

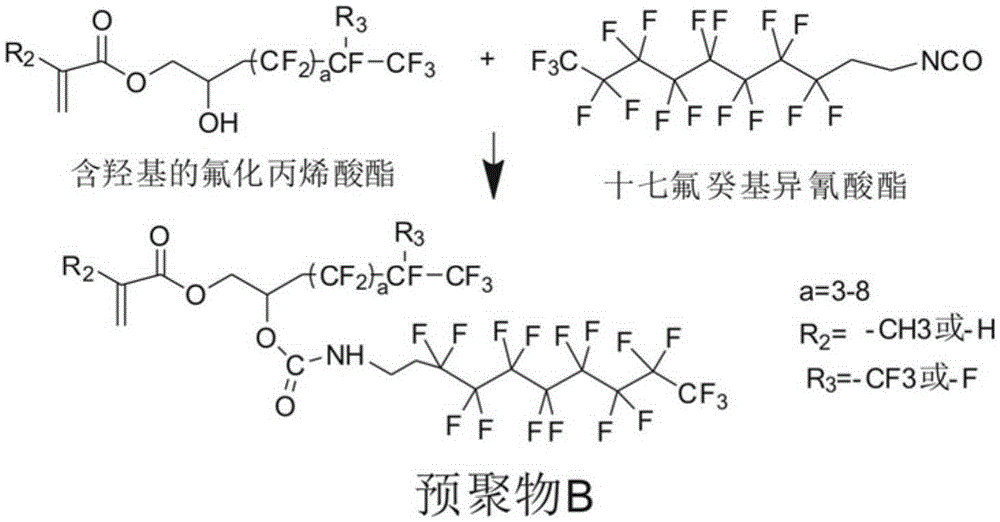

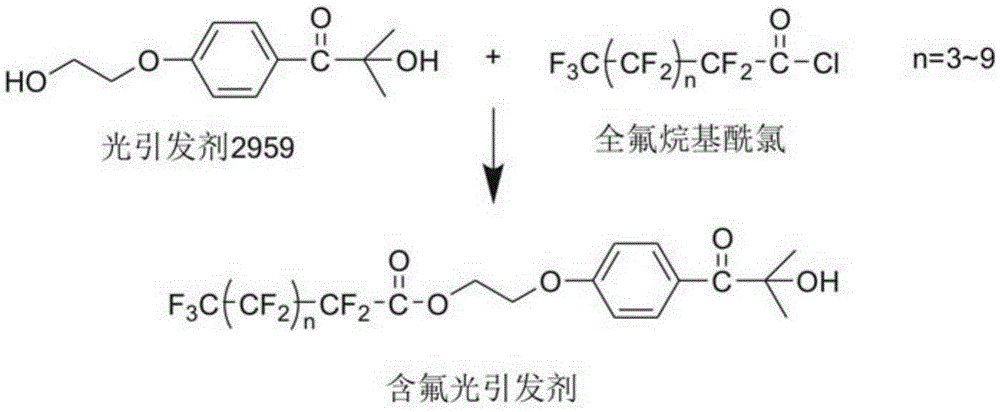

Method used

Image

Examples

Embodiment 1

[0048] A low refractive index optical fiber coating resin, the content of each component is: prepolymer A 50%, prepolymer B 20%, 1H, 1H, 2H, 2H-perfluorohexyl acrylate 17.5% by weight %, octafluoro-1,6-hexanediol diacrylate 8%, photoinitiator TPO1%, fluorinated modified photoinitiator 29592%, photoinitiator 1841%, vinyltriethoxysilane 0.5%, Total 100%.

[0049] The preparation method of the above-mentioned optical fiber coating resin is: according to the above-mentioned ratio, weigh each raw material component, use a disperser to stir at a speed of 1000 rpm at about 40 ° C for 60 minutes, and after the photoinitiator is completely dissolved, use 1500 Filter through a mesh filter, place in a 40°C oven for degassing for 1 day, and then get the finished product.

[0050] The viscosity of the optical fiber coating resin prepared in this embodiment is 4323mpa.s (25°C), the elongation at break is 24%, the specific modulus (2.5% elongation) is 156MPa, the tensile strength is 12.2MPa...

Embodiment 2

[0052] A low refractive index optical fiber coating resin, the content of each component is: prepolymer A65%, 1H,1H,2H,2H-perfluorodecyl acrylate 28.7%, octafluoro- 1,6-hexanediol diacrylate 3%, photoinitiator 8190.3%, fluorinated modified photoinitiator 29592%, heptadecafluorodecyltriethoxysilane 1%, total 100%.

[0053] The preparation method of the above-mentioned optical fiber coating resin is: according to the above-mentioned ratio, weigh each raw material component, use a disperser to stir at a speed of 1000 rpm at about 40 ° C for 60 minutes, and after the photoinitiator is completely dissolved, use 1500 Filter through a mesh filter, place it in a 40°C oven for degassing for 1 day, and then get the finished product.

[0054] The optical fiber coating resin prepared in this example has a viscosity of 6234mpa.s (25°C), an elongation at break of 33.4%, a specific modulus (2.5% elongation) of 209.2MPa, and a tensile strength of 11.2MPa. Rate 1.353 (25°C).

Embodiment 3

[0056] A low refractive index optical fiber coating resin, the content of each component is as follows: prepolymer A 35%, prepolymer B 35%, octafluoro-1,6-hexanediol diacrylate 25% %, photoinitiator TPO1%, 1843%, γ-methacryloxypropyl trimethoxysilane 1%, a total of 100%.

[0057] The preparation method of the above-mentioned optical fiber coating resin is: according to the above-mentioned ratio, weigh each raw material component, use a disperser to stir at a speed of 1000 rpm at about 40 ° C for 60 minutes, and after the photoinitiator is completely dissolved, use 1500 Filter through a mesh filter, place it in a 40°C oven for degassing for 1 day, and then get the finished product.

[0058] The viscosity of the fiber coating resin prepared in this example is 2387mpa.s (25°C), the elongation at break is 20.4%, the specific modulus (2.5% elongation) is 121MPa, the tensile strength is 13.3MPa, and the refractive index 1.394 (25°C).

[0059] The resin described in the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com