Lead-free aluminum paste for solar cell and preparation method thereof

A technology for solar cells and aluminum backing, applied to conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve problems such as low conversion efficiency, affecting the overall performance of cells, and high contact resistance. Increased open circuit voltage and conversion efficiency, improved battery conversion efficiency, and reduced warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing the above-mentioned lead-free back aluminum paste for solar cells, comprising the following steps:

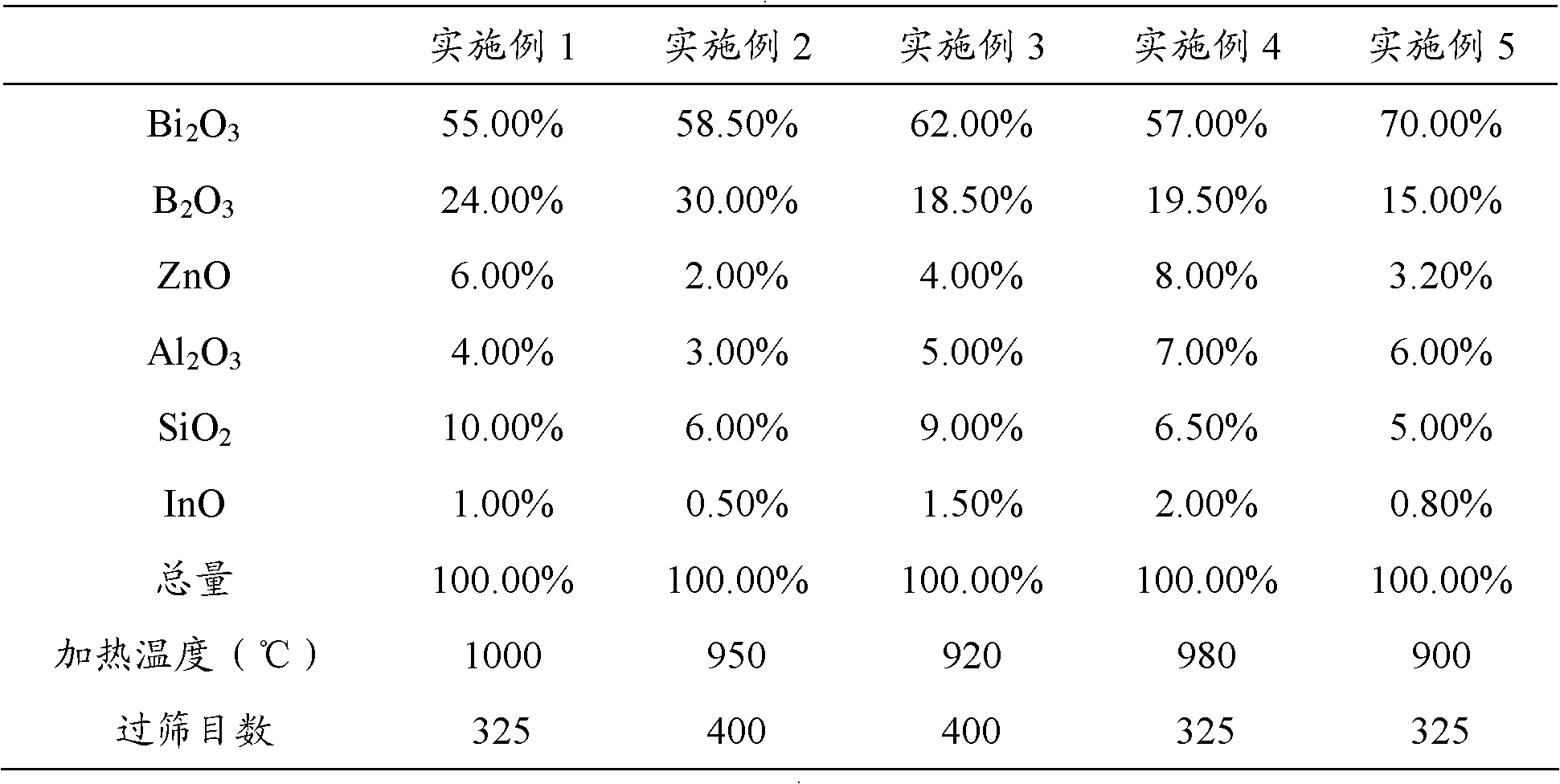

[0034] 1) According to the mass percentage, 55% ~ 70% Bi 2 o 3 , 15%~30%B 2 o 3 , 2% ~ 8% ZnO, 3% ~ 7% Al 2 o 3 , 5% ~ 10% SiO 2Mix with 0.5%~2% InO evenly, the sum of the mass percentage of each component is 100%; the above mixture is melted, cooled, ball milled and sieved to obtain lead-free glass powder, particle size range of lead-free glass powder: 0.5μm~ 3.0μm, softening point 400℃~600℃, expansion coefficient: 58×10 -7 / K~70×10 -7 / K;

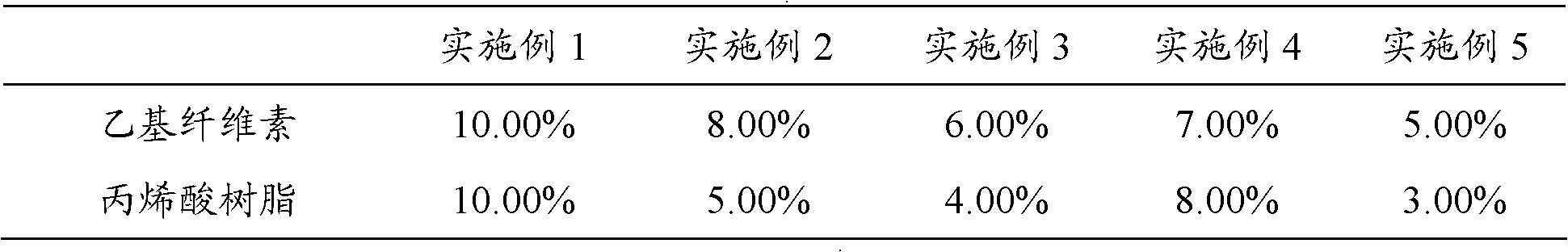

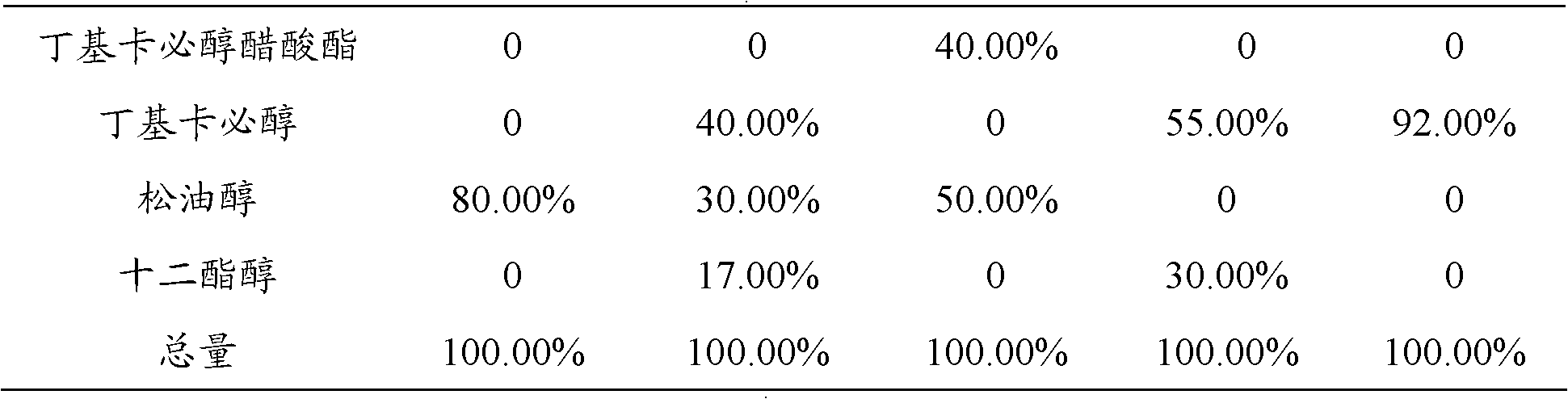

[0035] 2) Add 5% to 10% of ethyl cellulose resin and 3% to 10% of acrylic resin to 80% to 92% of butyl carbitol acetate, butyl carbitol, pine In a mixture of one or more of oleyl alcohol and lauryl alcohol, the sum of the mass percentages of each component is 100%; it is completely dissolved at a constant temperature of 80°C, and is filtered through a 250-mesh stand...

Embodiment 1

[0048] 1) Preparation of lead-free glass powder

[0049] 55% Bi by mass percentage 2 o 3 , 24%B 2 o 3 , 6% ZnO, 4% Al 2 o 3 , 10% SiO2 2 After mixing evenly with 1% InO, heat it to 1000°C and keep it warm for 2 hours, then cool the glass powder, ball mill it until the particle size of the lead-free glass powder is 0.5 μm to 3.0 μm, and filter it through a 325-mesh standard sieve for use. At this time, the softening point of the lead-free glass powder is 400℃~600℃, and the expansion coefficient: 58×10 -7 / K~70×10 -7 / K.

[0050] 2) Preparation of organic vehicle

[0051] Add 10% ethyl cellulose resin and 10% acrylic acid resin to 80% terpineol diluent according to mass percentage, and dissolve completely under constant temperature conditions of 80°C. Organic vehicle was obtained by filtration.

[0052] 3) Preparation of slurry

[0053] 0.5% of the above-mentioned lead-free glass powder, 10% of the above-mentioned organic vehicle, 80% of the fine spherical aluminum p...

Embodiment 2

[0057] 1) Preparation of lead-free glass powder

[0058] By mass percentage will 58.5% Bi 2 o 3 , 30%B 2 o 3 , 2% ZnO, 3% Al 2 o 3 , 6% SiO 2 After mixing evenly with 0.5% InO, heat it to 950°C and keep it warm for 2 hours, then cool the glass powder, ball mill it until the particle size of the lead-free glass powder is 0.5 μm to 3.0 μm, and filter it through a 400-mesh standard sieve for use. At this time, the softening point of the lead-free glass powder is 400℃~600℃, and the expansion coefficient: 58×10 -7 / K~70×10 -7 / K.

[0059] 2) Preparation of organic vehicle

[0060] Add 8% ethyl cellulose resin and 5% acrylic resin to the diluent composed of 40% butyl carbitol, 30% terpineol and 17% lauryl alcohol by mass percentage, and keep the temperature at 80°C Under the conditions, it was completely dissolved, and after 2 hours of heat preservation, the organic carrier was obtained by filtering with a 250-mesh standard sieve.

[0061] 3) Preparation of slurry

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com