Stamping drawing oil used for water-based stainless steel and preparation method of stamping drawing oil

A technology for stamping and stretching and stainless steel, which is applied in the field of stamping and stretching oil for water-based stainless steel and its preparation, can solve the problems of uncontrollable viscosity, unfriendly environment, difficult cleaning, etc., and achieves reduced formulation cost, simple formulation and preparation steps. , Excellent lubricity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the water-based stainless steel stamping drawing oil of present embodiment 1, make by following steps and comprise the following steps:

[0021] 1) Mix 10 parts of pentaerythyl oleate, 5240 parts of chlorinated paraffin, 5 parts of sulfurized isobutylene, 5 parts of vulcanized lard or vulcanized cottonseed oil, 3 parts of antirust agent, and 10 parts of white oil, mix them at 40~ At 60°C, continue to stir for 30 minutes;

[0022] 2) Add 1 part of bactericide and 0.1 part of bactericide to the mixed liquid that is stirred and mixed, control the temperature at 50-60°C, and continue stirring for 1-2 hours;

[0023] 3), keep the temperature, add 10 parts of compound emulsifier to the mixture in step 2), control the temperature at 60°C, and stir for 1 hour;

[0024] 4), the mixed solution in step 3) is cooled and allowed to stand before canning.

[0025] After cooling, the water-based stainless steel punching and drawing oil of the present invention is obtained.

[002...

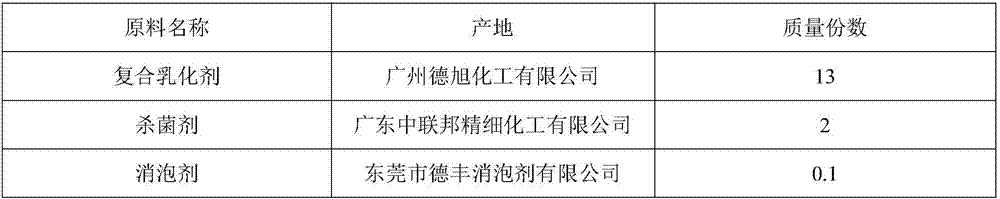

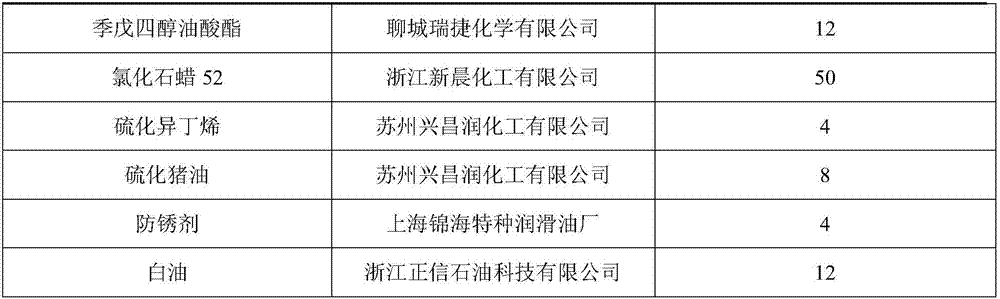

Embodiment 2

[0029] In the water-based stainless steel stamping drawing oil of present embodiment 2, make by following steps and comprise the following steps:

[0030] 1) Mix 12 parts of tetrapentapentyl oleate, 5250 parts of chlorinated paraffin, 4 parts of sulfurized isobutylene, 8 parts of vulcanized lard oil or vulcanized cottonseed oil, 4 parts of antirust agent, and 12 parts of white oil. At 60°C, continue to stir for 30 minutes;

[0031] 2) Add 2 parts of fungicide and 0.1 part of fungicide to the mixed solution above, control the temperature at 50-60°C, and continue to stir for 1-2 hours; (add defoamer and fungicide together)

[0032] 3), keep the temperature, add 13 parts of compound emulsifier to the mixture in step 2), control the temperature at 60°C, and stir for 1 hour;

[0033] 4), the mixed solution in step 3) is cooled and allowed to stand before canning.

[0034] After cooling, the water-based stainless steel punching and drawing oil of the present invention is obtained....

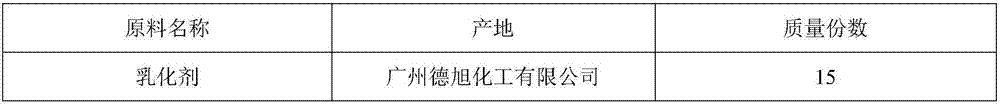

Embodiment 3

[0039] The water-based stainless steel stamping and stretching oil in present embodiment 3 is made by the following steps and comprises the following steps:

[0040] A method for preparing water-based stainless steel stamping drawing oil, comprising the following steps:

[0041] 1) Mix 15 parts of pentaerythyl oleate, 5260 parts of chlorinated paraffin, 10 parts of sulfurized isobutylene, 10 parts of vulcanized lard or vulcanized cottonseed oil, 5 parts of antirust agent, and 15 parts of white oil. At 60°C, continue to stir for 30 minutes;

[0042] 2) Add 3 parts of bactericide and 0.1 part of bactericide to the mixed solution above, control the temperature at 50-60°C, and continue to stir for 1-2 hours; (add defoamer and bactericide together)

[0043] 3), keep the temperature, add 15 parts of compound emulsifier to the mixture in step 2), control the temperature at 60°C, and stir for 1 hour;

[0044] 4), the mixed solution in step 3) is cooled and allowed to stand before ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com