Healant for chemical pipes and preparation method thereof

A technology for chemical pipelines and repairing agents, applied in chemical instruments and methods, pipe components, adhesives, etc., can solve the problems of difficult processing, easy recurrence, short plugging time, etc., to improve chemical resistance, strengthen performance indicators, and appearance. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A special repairing agent for chemical pipelines and a preparation method thereof, the method comprising the following process steps:

[0049] Basic formula composition: 50kg modified epoxy resin, 1.5kg amino-terminated polyol ester modifier, 3kg fumed silica, 20kg nano-silica, 1.5kg antioxidant 1010, 0.05kg graphite, 1kg silver aluminum powder .

[0050] (1) Preparation of modified epoxy resin:

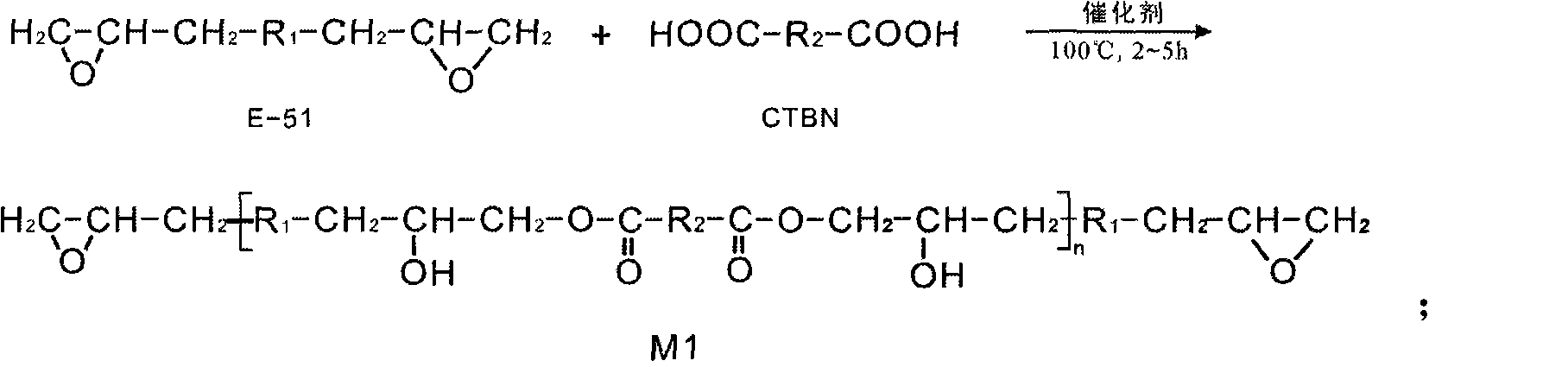

[0051] a. Weigh 85kg of E-51 epoxy resin, 15kg of CTBN, and 0.25kg of transesterification catalyst stannous octoate in a three-necked flask, insert a thermometer into one mouth, heat and stir, control the temperature at 100°C, and react for 4.5h. Subsequently with excessive deionized water precipitation washing product, obtain the prepolymer M1 of CTBN modified epoxy resin after vacuum drying, its reaction is as follows:

[0052]

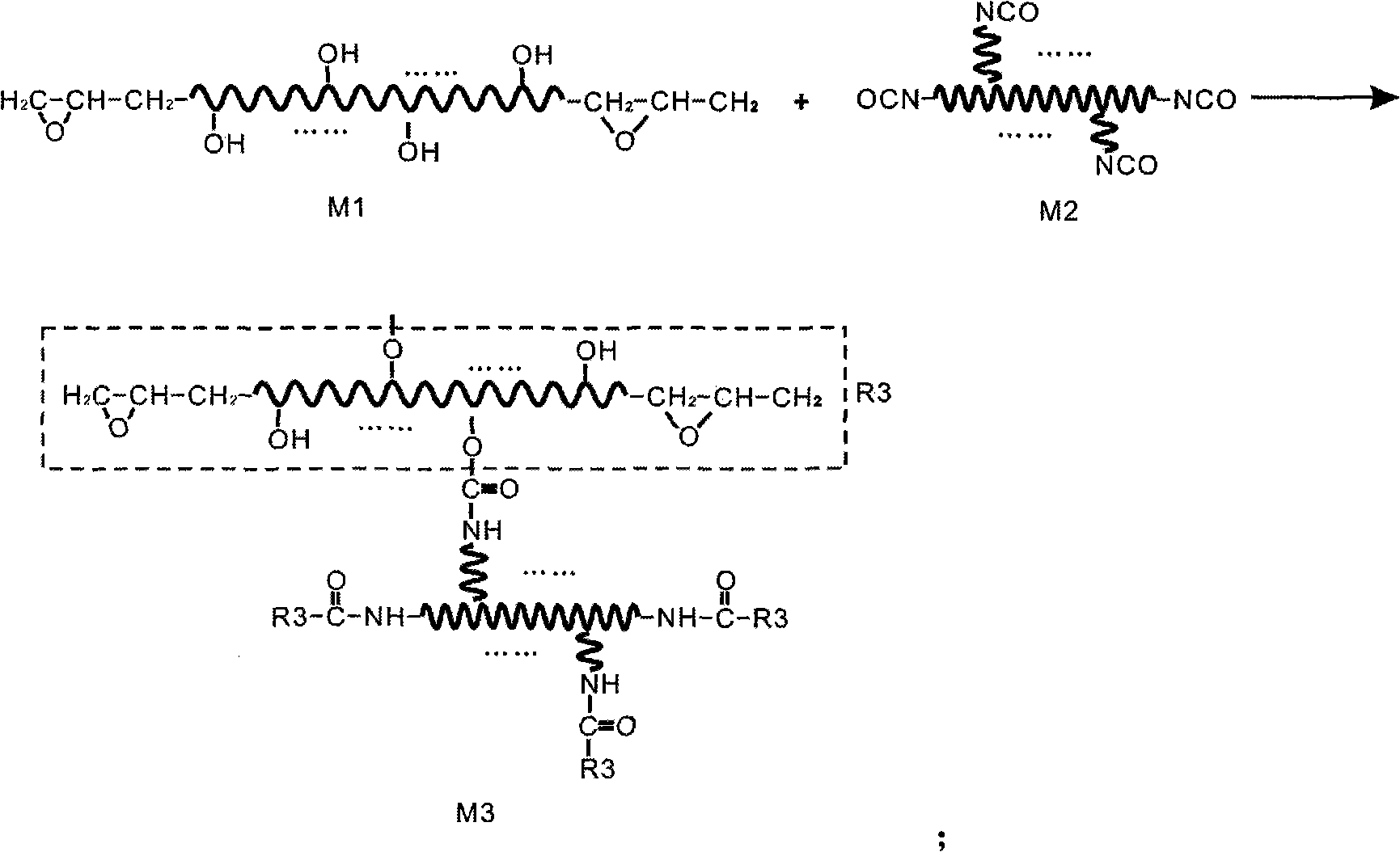

[0053] b. To synthesize polyurethane prepolymer, mix 95kg of TDI and 5kg of N-330 polyether polyol into a three-neck bottle, and pass in nitro...

Embodiment 2

[0060] A special repairing agent for chemical pipelines and a preparation method thereof, the method comprising the following process steps:

[0061] Basic formula composition: 60kg modified epoxy resin, 1.5kg coupling agent KH-560, 1kg thixotropic agent fumed silica, 30kg nano-silica, 1.5kg antioxidant B315 and 0.5kg ultraviolet absorber UV-9 As anti-aging agent, 3kg silver aluminum powder.

[0062] (1) Preparation of modified epoxy resin:

[0063] a. Weigh 80kg of E-51 epoxy resin, 20kg of CTBN, and 0.25kg of transesterification catalyst organotin in a three-necked flask according to the proportion, insert a thermometer in one mouth, heat and stir, control the temperature at 100°C, react for 5h, and then use Excessive deionized water precipitates and washes the product, and obtains the prepolymer M1 of CTBN modified epoxy resin after vacuum drying;

[0064] b. Synthesis of polyurethane prepolymer: mix 95kg of TDI and 5kg of N-330 polyether polyol into a three-necked bottle...

Embodiment 3

[0070] A preparation method for a chemical pipeline repair agent, characterized in that the method comprises the following steps:

[0071] (1) Prepare modified epoxy resin:

[0072] a. Mix 80kg of commercially available E-51 epoxy resin, 20kg of hydroxyl-terminated nitrile rubber (CTBN), and 0.2kg of transesterification catalyst quaternary ammonium salt, control the reaction temperature at 90-100°C, stir for 5 hours, and then use The precipitated product was washed with ionic water and vacuum-dried to obtain CTBN-modified epoxy resin prepolymer M1;

[0073] b. Mix 95kg of toluene diisocyanate (TDI) with 5kg of ethylenediamine-based polyether polyol, under the protection of nitrogen, control the reaction temperature to 80°C, and stir for 4 hours to obtain a clear and transparent polyurethane oligomer M2;

[0074] c. Mix 95kg of epoxy resin prepolymer M1 with 5kg of polyurethane oligomer M2, control the reaction temperature to 90°C, and stir for 4 hours to obtain grafted modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com