Polyvinylidene fluoride-polyethylene composite material, preparation method thereof and insulator sheath

A polyvinylidene fluoride and composite material technology, applied in the field of materials, can solve the problems of low production efficiency, incomplete vulcanization of silicone rubber, long molding cycle of silicone rubber, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

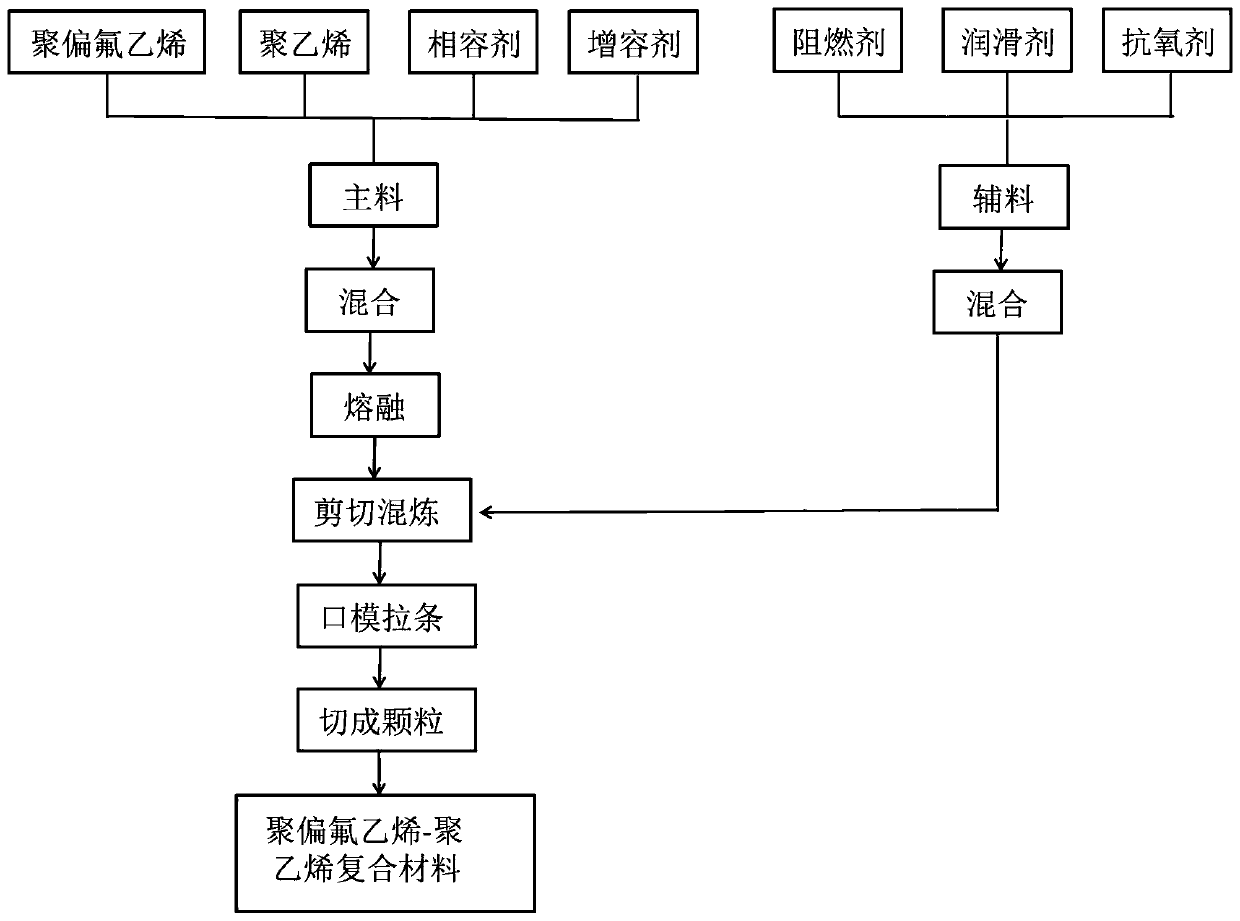

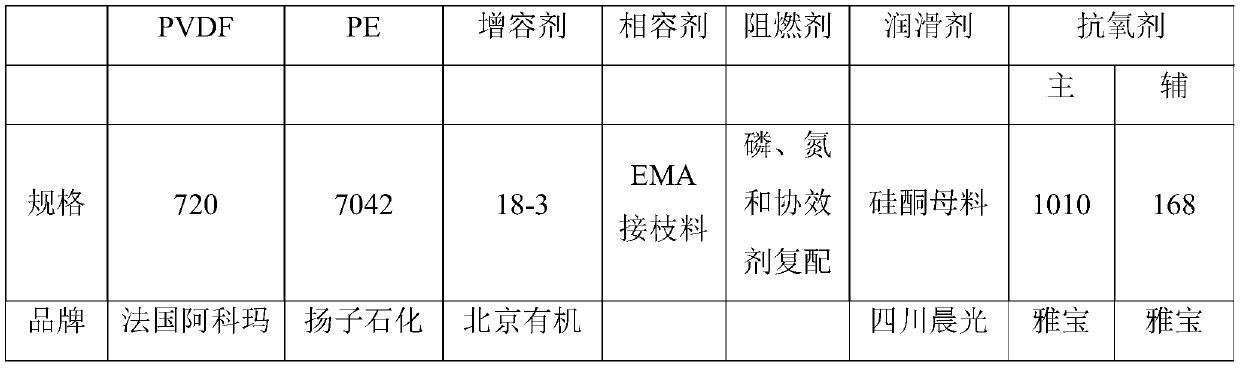

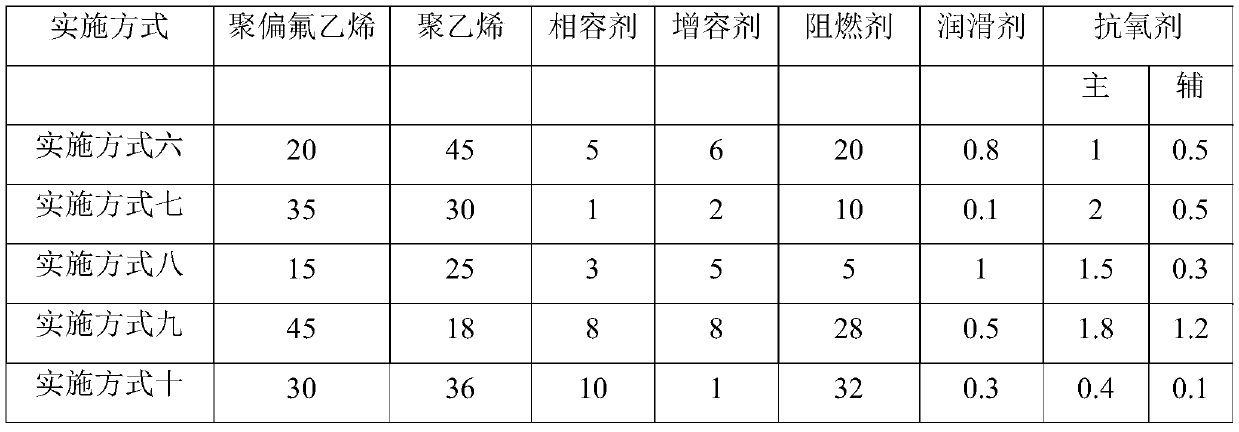

[0021] Such as figure 1 As shown, this embodiment 1 provides a polyvinylidene fluoride-polyethylene composite material, which consists of: polyvinylidene fluoride: 10-50 parts; polyethylene: 10-50 parts; compatibilizer: 1 -10 parts; compatibilizer: 1-10 parts; flame retardant: 5-35 parts; lubricant: 0.1-1 part; and antioxidant: 0.5-3 parts. Preferably, the polyvinylidene fluoride is 15-25 parts.

[0022] Melt flow rate (MFR) is at a certain temperature and pressure, the resin melt passes through the standard capillary, the unit is g / 10min. Melt flow rate is an important reference for selecting plastic processing materials and grades, which can make the selected raw materials better meet the requirements of processing technology, and improve the reliability and quality of products in molding. Therefore, in plastic processing, by measuring the flow rate of plastics, the structural factors of polymers can be studied to measure the fluidity of plastic melts.

[0023] Optionally...

Embodiment 2

[0036] See figure 1 , on the basis of Example 1, this Example 2 provides a method for preparing a polyvinylidene fluoride-polyethylene composite material, including the following steps: Step S1, adding the main material and auxiliary materials into the twin-screw extruder respectively, Through shearing, melting and mixing under the action of the screw; step S2, die drawing, that is, drawing into strips through the die; and step S3, cutting into pellets.

[0037] Optionally, the main ingredients include: polyvinylidene fluoride: 10-50 parts; polyethylene: 10-50 parts; compatibilizer: 1-10 parts; compatibilizer: 1-10 parts.

[0038] Optionally, the auxiliary materials include by weight: flame retardant: 5-35 parts; lubricant: 0.1-1 part; antioxidant: 0.5-3 parts.

[0039]The specific preparation steps are as follows: First, add 10-50 parts of polyvinylidene fluoride, 10-50 parts of polyethylene, 1-10 parts of compatibilizer, and 1-10 parts of compatibilizer into a double-cone s...

Embodiment 3

[0042] On the basis of Embodiment 1 and Embodiment 2, this Embodiment 3 provides an insulator sheath, including: the polyvinylidene fluoride-polyethylene composite material as described above; the polyvinylidene fluoride-polyethylene The composite material is suitable for premolding, injection, pressure holding and cooling forming by an injection molding machine, that is, the insulator sheath.

[0043] Optionally, the temperature of the injection molding machine is set at 175-220°C, and may be 190°C, 200°C, or 210°C.

[0044] Regarding the component content of the polyvinylidene fluoride-polyethylene composite material and the specific implementation process, please refer to the relevant discussions of Examples 1 and 2, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com