Anti-compression air-tight seal aviation electric connector

An electrical connector, aviation technology, applied in the direction of connection, connection component installation, connection device components, etc., can solve the problems of decreased insulation performance and environmental resistance, large size of electrical connector, low pressure resistance, etc. Achieve the effect of improving the overall compressive performance, novel and compact structure, and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

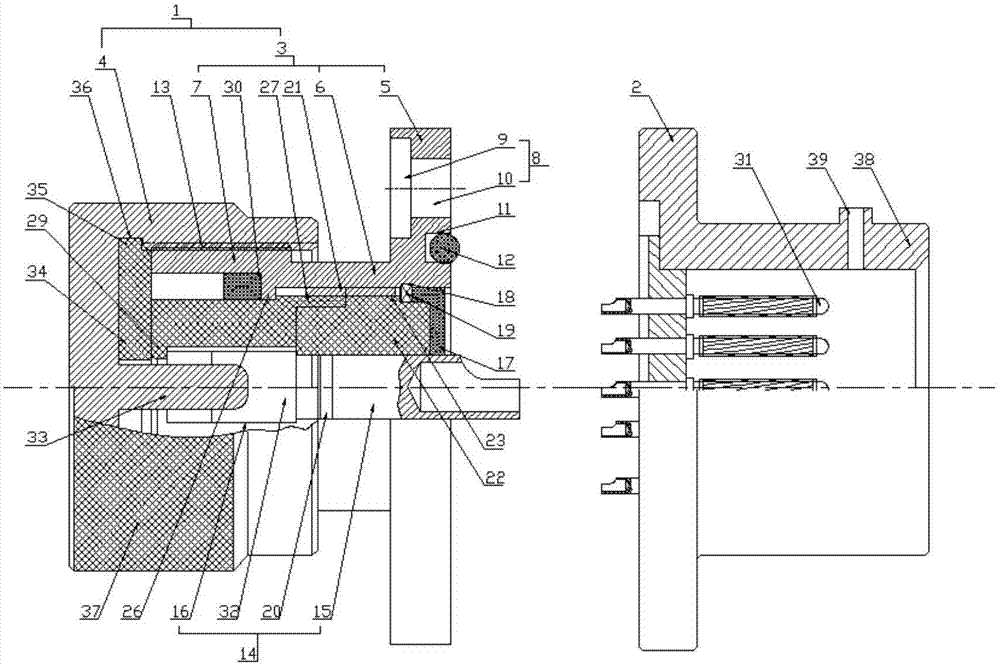

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

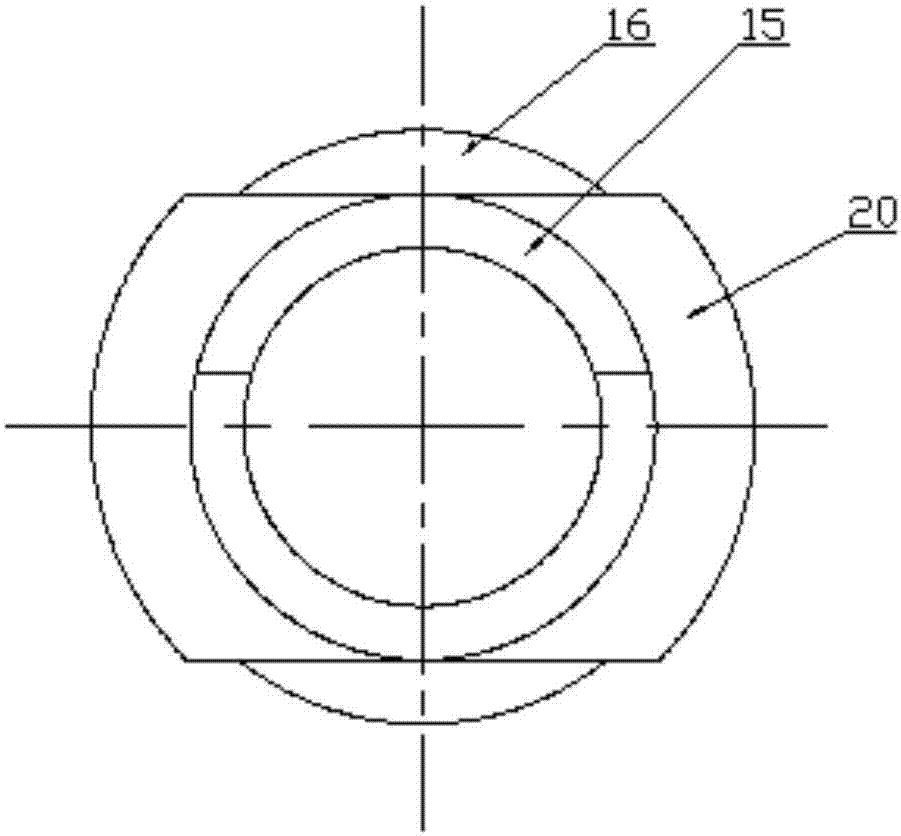

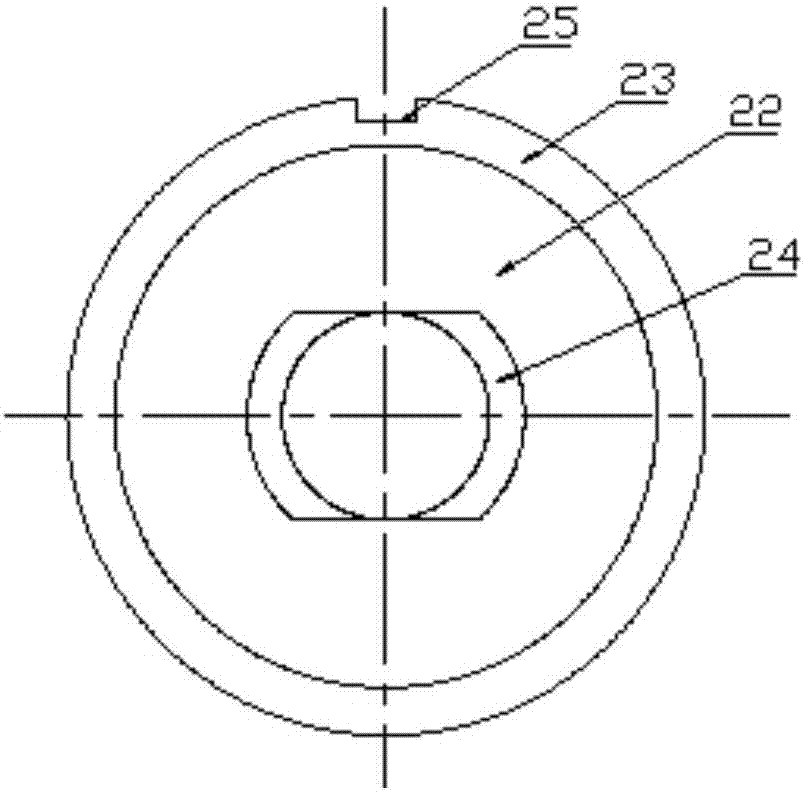

[0026] A pressure-resistant airtight aviation electrical connector, including a socket 1 and a plug 2, wherein the socket 1 includes a round seat 3 and a protective cover 4, and the round seat 3 includes a flange 5 connected into an integral structure, a connecting A sleeve 6 and a threaded sleeve 7, the flange 5 is provided with a number of connection holes 8, a number of connection holes 8 are evenly spaced around the flange 5, and the connection holes 8 include coaxial and interconnected primary holes 9 and The secondary hole 10, the aperture of the primary hole 9 is larger than the aperture of the secondary hole 10, the surface of the flange 5 is provided with a sealing groove 11, and the sealing groove 11 is provided with an O-shaped nitrile rubber ring 12 ;

[0027] A matching thread 13 is provided between the outer wall of the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com