Alloy-copper embedded copying silver material of automobile electric appliance and method for making alloy-copper embedded copying silver material

A technology for automotive electrical appliances and manufacturing methods, applied in contact materials, circuits, electrical switches, etc., can solve the problems of breaking capacity of electrical contacts, resistance to electrical corrosion and welding resistance, insufficient cut-off current, etc., and achieve anti-fusion welding. The effect of strong performance, low production cost and high erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific diagrams.

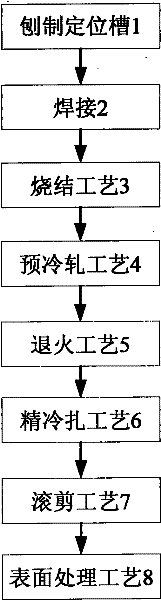

[0025] refer to figure 1 , figure 2 , a kind of manufacture method of alloy copper copper inlaid silver automotive electrical material, comprises the following steps:

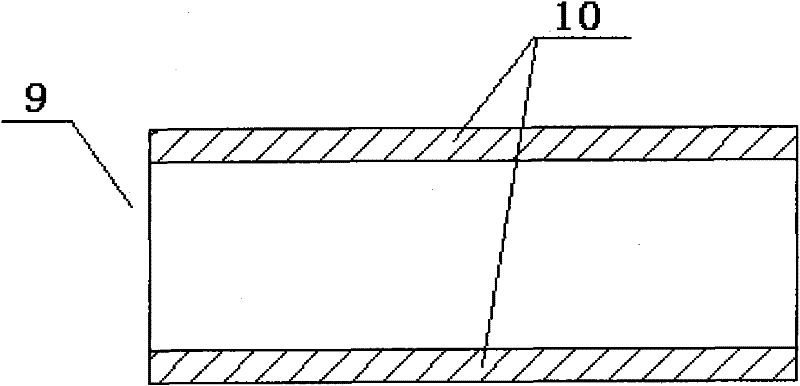

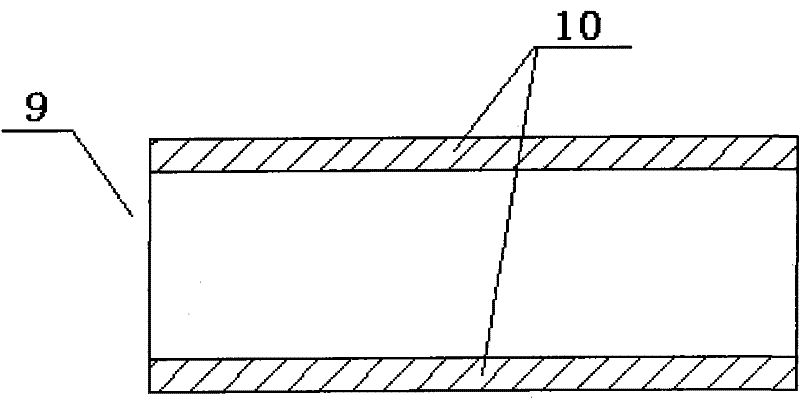

[0026] Planing positioning groove 1: Select the brass sheet substrate 9, preferably 62 brass sheets, plan the positioning grooves at the two edges of the brass sheet substrate 9 conforming surface, and brush the conforming surface. It is required that the surface of the material has no holes. Inclusion;

[0027] Welding 2: Wipe the matching surface with alcohol and white gauze, and use argon arc welding to weld the silver bars 10 on the positioning grooves on the two edges of the brass plate substrate 9 to obtain the green body;

[0028] Sintering process 3: Put the green bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com