Copper-based electric contact material for low-voltage apparatus

A technology of low-voltage electrical appliances and electrical contact materials, applied in the field of material design and preparation technology for copper-based electrical contact materials, can solve the problems of less application, high electrical and thermal conductivity, strength, hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1 Ni—3%, Zr—0.5%, Y—0.5%, Cu is the balance, and the specific steps are described in detail in the detailed description.

Embodiment 2

[0013] Example 2 Ni—1%, Zr—0.3%, Y—0.2%, Cu is the balance, and the specific steps are described in detail in the detailed description.

Embodiment 3

[0014] Example 3 Ni—0.5%, Zr—0.1%, Y—0.1%, Cu is the balance, and the specific steps are described in detail in the detailed description.

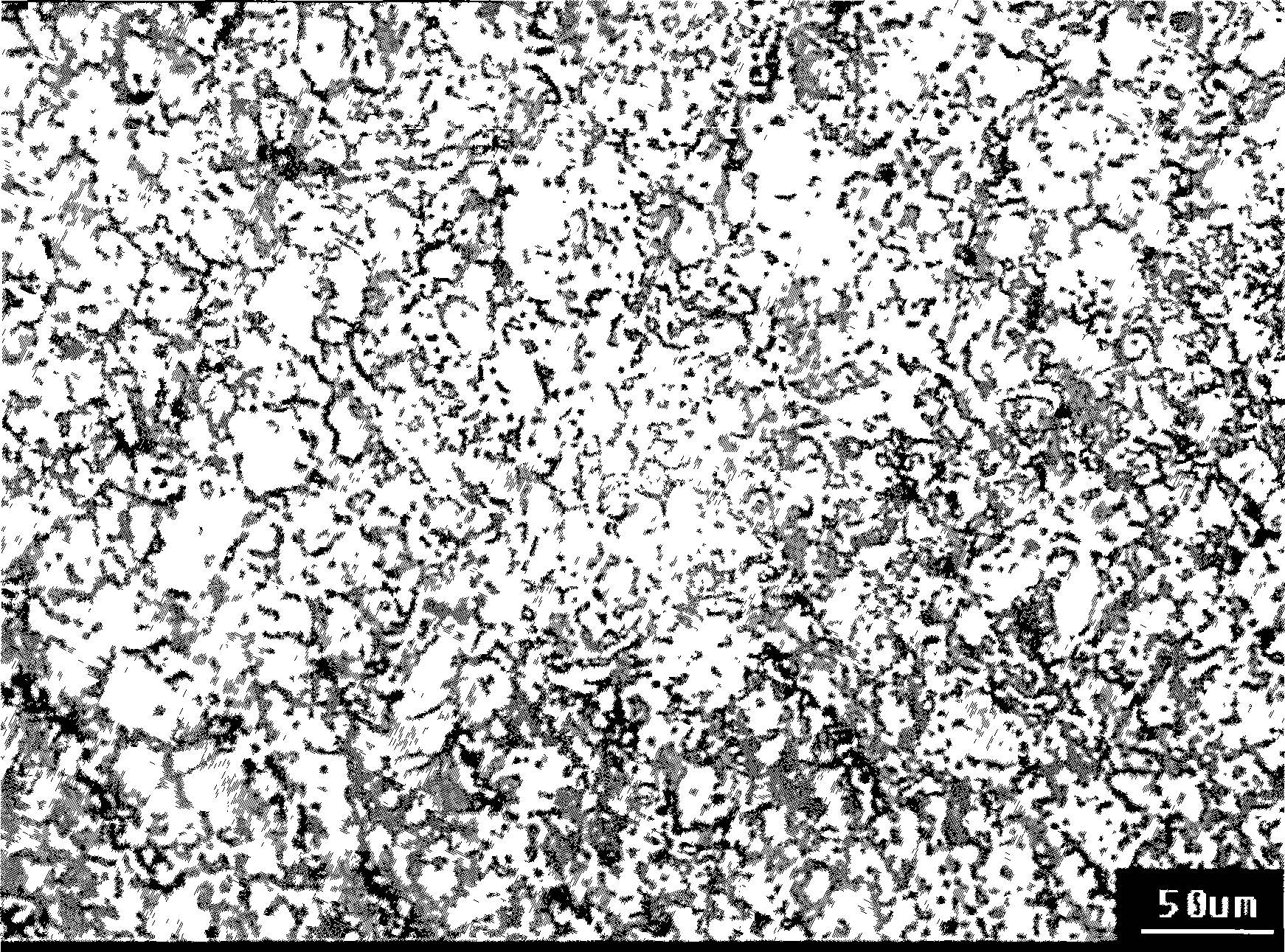

[0015] The organization and performance of the embodiment 2 prepared by the present invention can be seen from its microstructure as attached figure 1 It can be seen from the figure that the second phase exists in the state of particles in the microstructure, the distribution is diffuse and uniform, and there is no obvious segregation. The material density is 8.75g cm -3 , a small amount of voids in the material makes the density of the sample slightly lower than the theoretical density of 8.94g cm -3 ; Conductivity is 29.3Ms m -1 , the corresponding resistivity is 3.41μΩ·cm; hardness is HV105.4. Excellent oxidation resistance and arc ablation resistance, long service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com