Crimping structure for metal materials, and bus bar using said crimping structure

A technology for riveting structures and metal parts, which is applied to structural parts, riveting connections, and electrical component connections. It can solve problems such as resistance, electrical conversion efficiency and durability, and high resistance of bus bars. Effect of suppressing variation in resistance and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

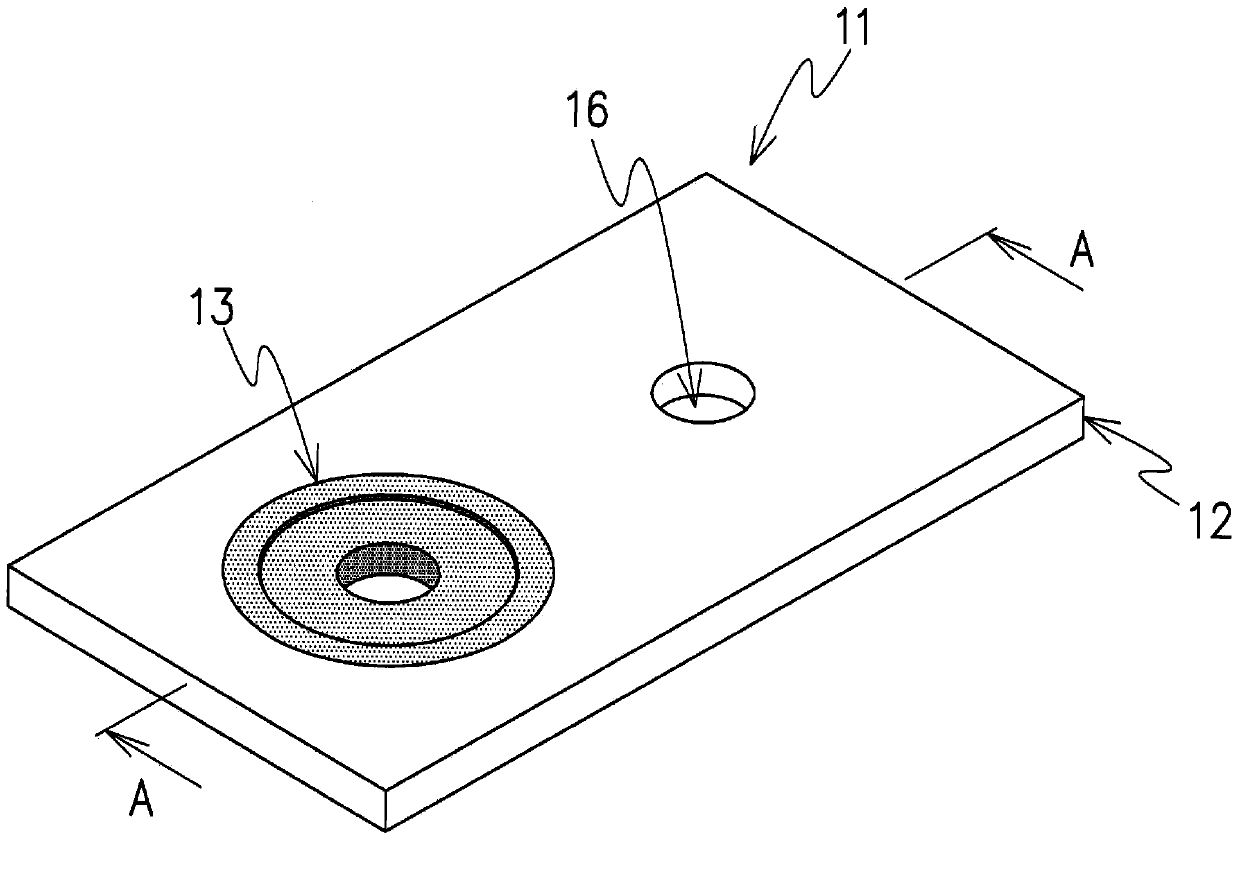

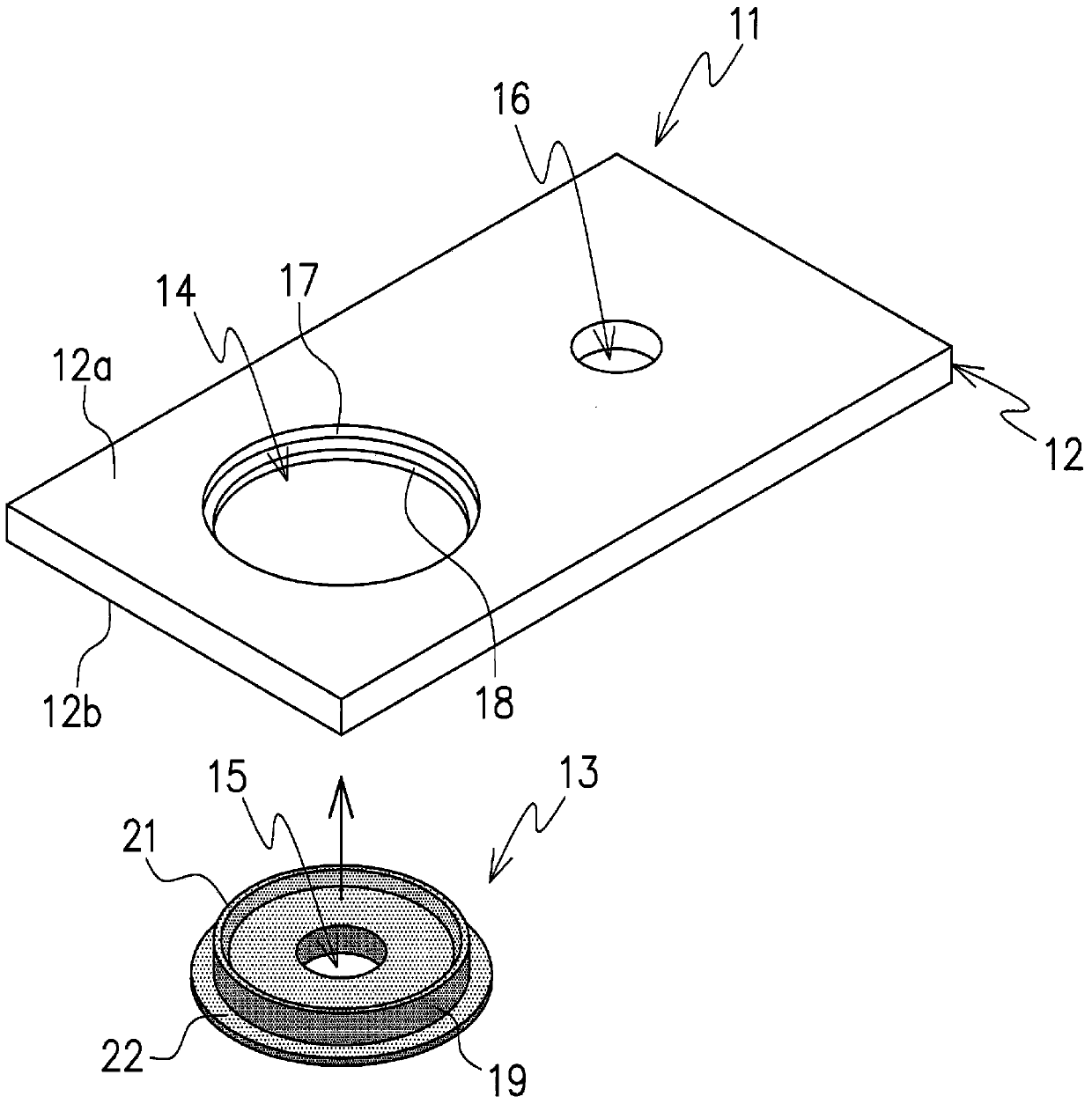

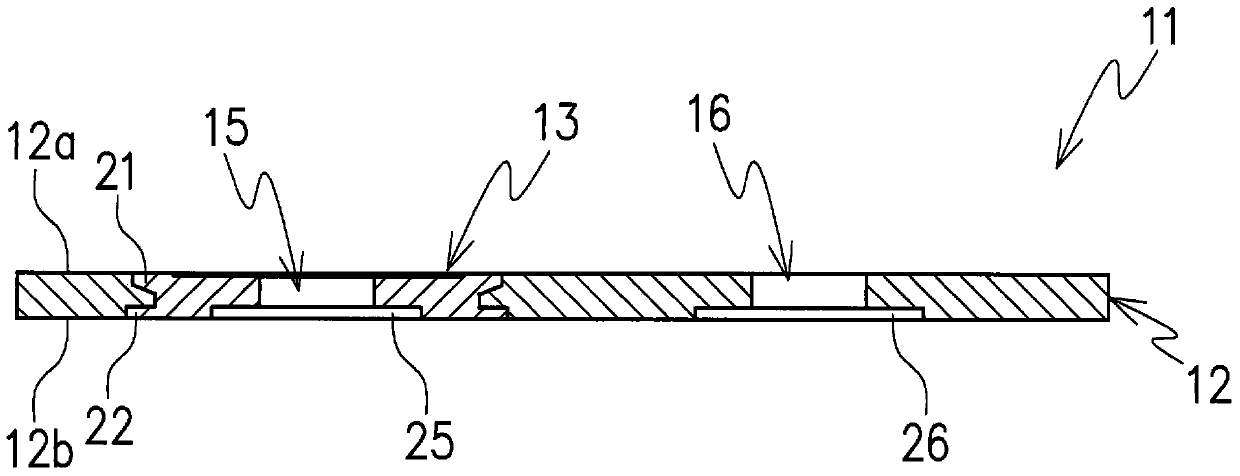

[0029] Hereinafter, embodiments of a riveting structure of a metal member according to the present invention and a bus bar using the riveting structure will be described in detail based on the drawings. figure 1 It is the appearance shape of the bus bar 11 formed using the riveting structure of the present invention, Figure 2 to Figure 7 The form of the caulking structure portion of the bus bar 11 described above is shown. In the caulking structure of the present invention, a disc-shaped conductive member 13 formed of a second metal material is fitted into and fixed to a flat metal plate 12 formed of a first metal material.

[0030] like figure 2 and image 3 As shown, the metal plate 12 is formed in a flat plate shape from a copper material as a first metal member, and has a first hole 14 opened at a predetermined position. The conductive member 13 is formed into a disc shape that can be inserted into the hole 14 by an aluminum material as a second metal piece, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com