Riveted structure of metal parts and bus bar using the riveted structure

A technology of riveting structure and metal parts, applied in the direction of structural parts, riveting connection, electrical component connection, etc., can solve the problems of non-negligible resistance, high busbar resistance, electrical conversion efficiency and durability effects, etc., to reduce resistance. , The effect of suppressing the deviation of resistance and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

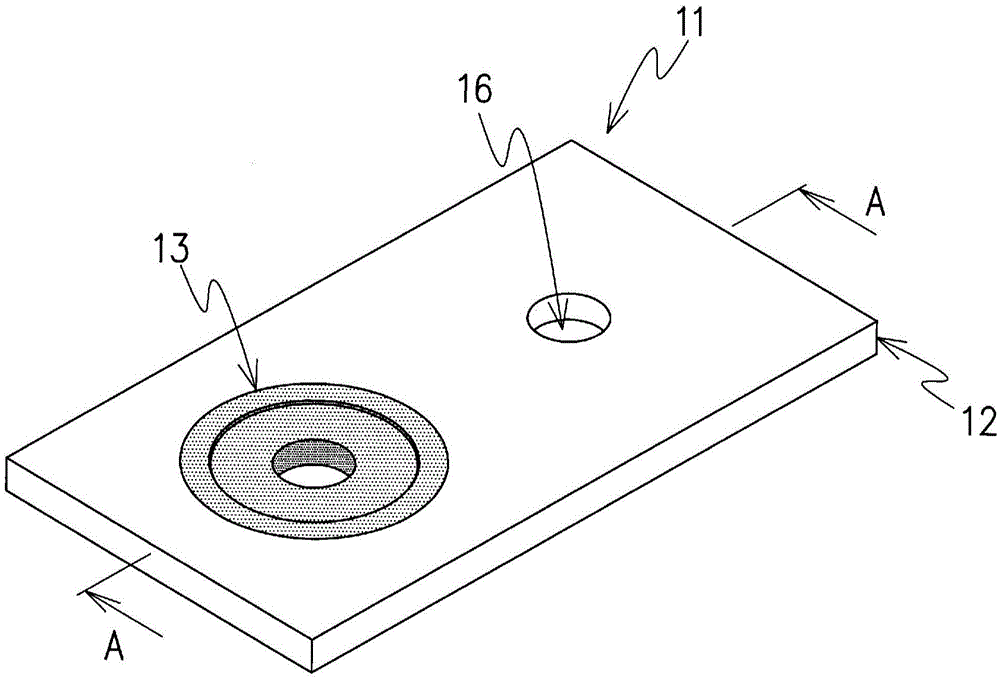

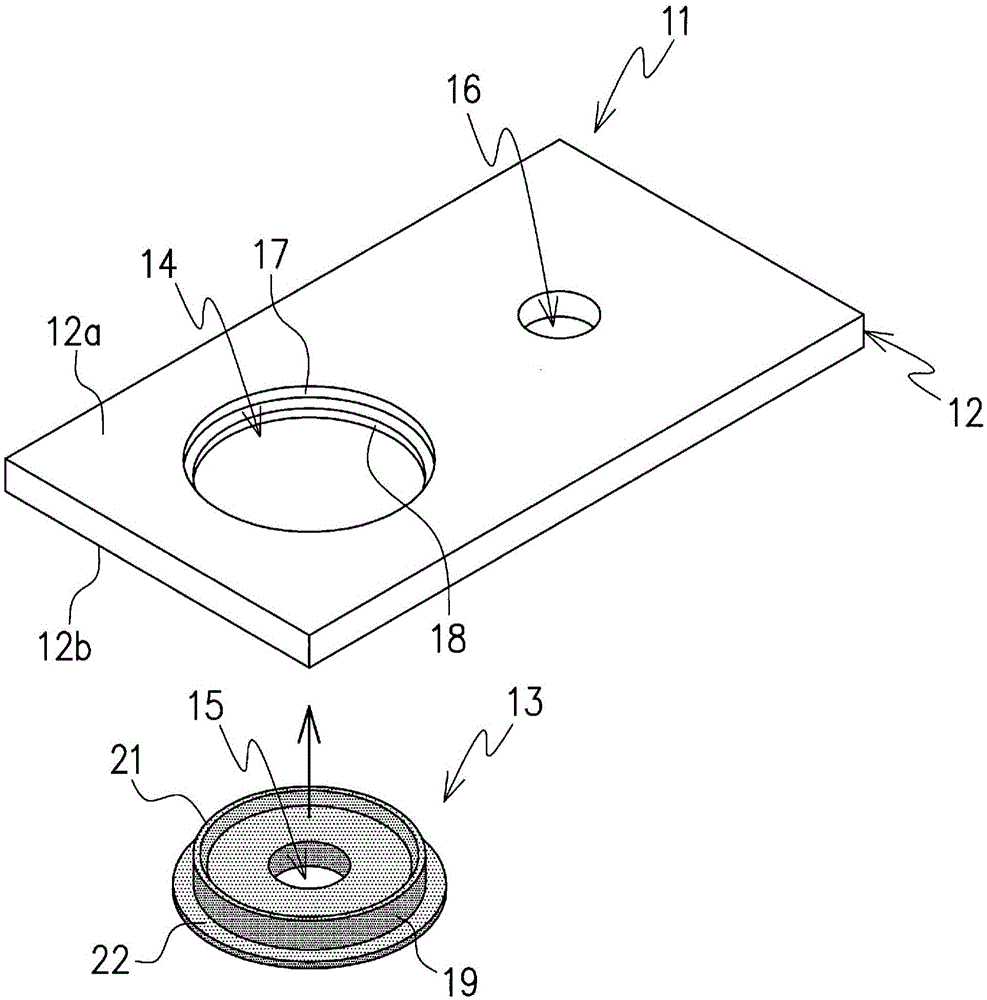

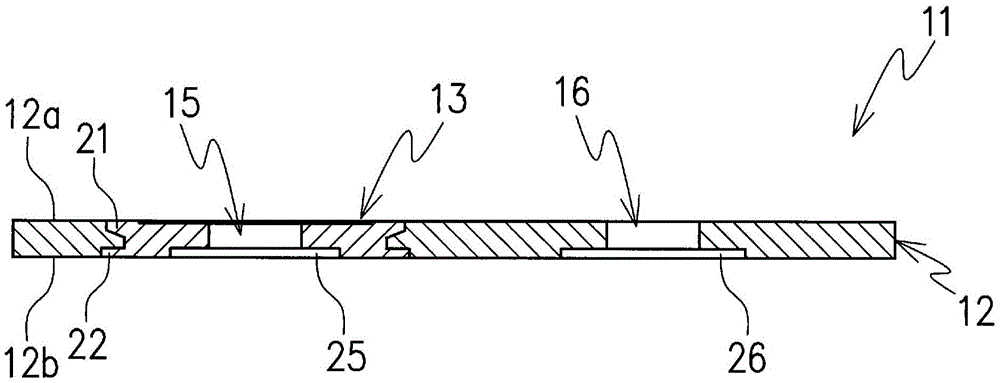

[0029] Hereinafter, embodiments of a riveting structure of a metal member according to the present invention and a bus bar using the riveting structure will be described in detail based on the drawings. figure 1 It is the appearance shape of the bus bar 11 formed using the riveting structure of the present invention, Figure 2 to Figure 7 The form of the caulking structure portion of the bus bar 11 described above is shown. In the caulking structure of the present invention, a disc-shaped conductive member 13 formed of a second metal material is fitted into and fixed to a flat metal plate 12 formed of a first metal material.

[0030] Such as figure 2 and image 3 As shown, the metal plate 12 is formed in a flat plate shape from a copper material as a first metal member, and has a first hole 14 opened at a predetermined position. The conductive member 13 is formed into a disc shape that can be inserted into the hole 14 by an aluminum material as a second metal piece, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com