Changeover valve

A switching valve and switching tube technology, applied in the field of switching valves, can solve problems such as automatic reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

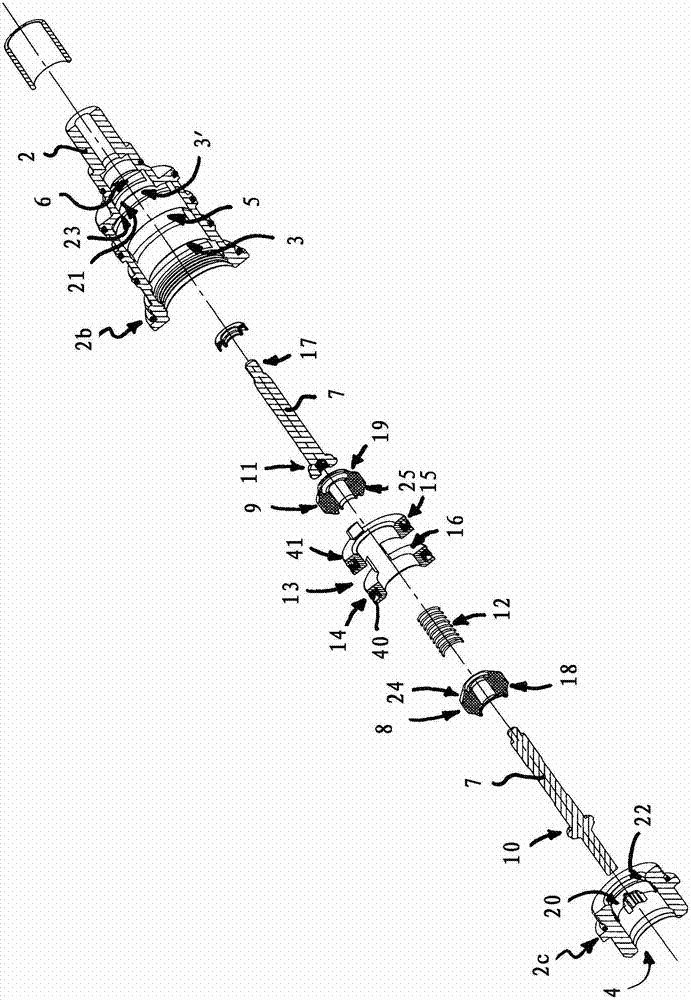

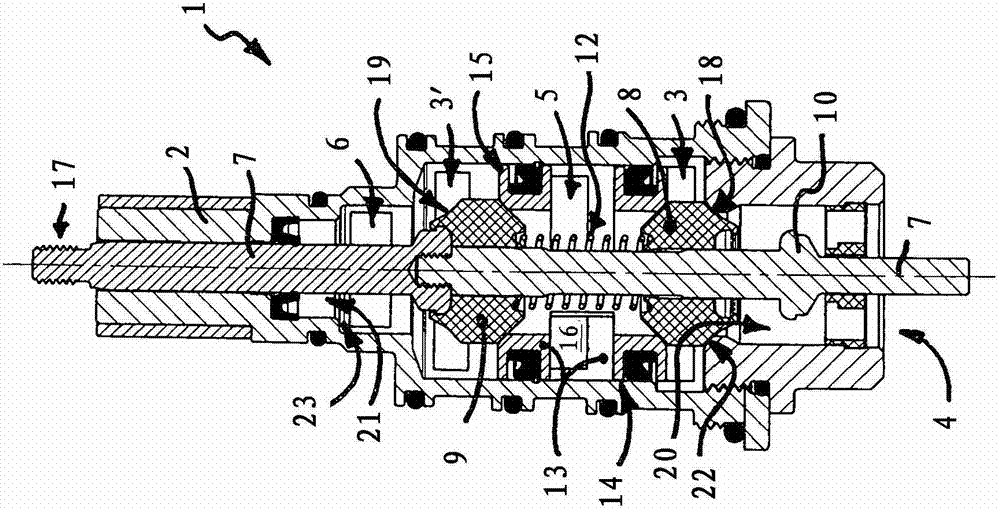

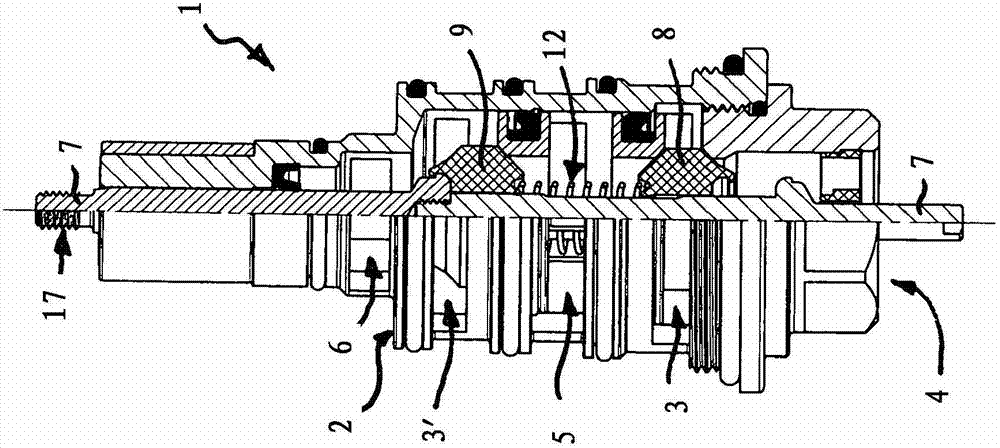

[0032] Figures 1 to 11 A changeover valve 1 configured as a 4-position, 3-way valve is shown. The inlet of the switchover valve 1 is connected, for example, to a water supply, while the outlet of the switchover valve 1 leads selectively to a bathtub outlet fitting, a flexible hand shower or, for example, to a fixed spray head.

[0033] Switching valve 1 has the Figures 1 to 4 The valve housing 2 shown in detail in , has two inlet holes 3, 3' serving as inlets and three outlet holes 4, 5 and 6 serving as outlets. The valve housing 2 can be constructed in one or more parts; the valve housing 2 is here constructed in two parts and has a fitting housing 201 (see Figures 5 to 8 ) into the cartridge 2b and the threaded joint 2c used as the end-side termination of the fitting housing 201 (see Figures 1 to 4). Of the three outlet holes 4, 5, 6, each outlet hole can be selectively assigned to the inlet holes 3, 3' On the switching shaft 7 two sealing elements 8 , 9 are gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com