Tobacco product and preparation method thereof

A technology of tobacco products and coating liquid, applied in the direction of tobacco, tobacco preparation, tobacco processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

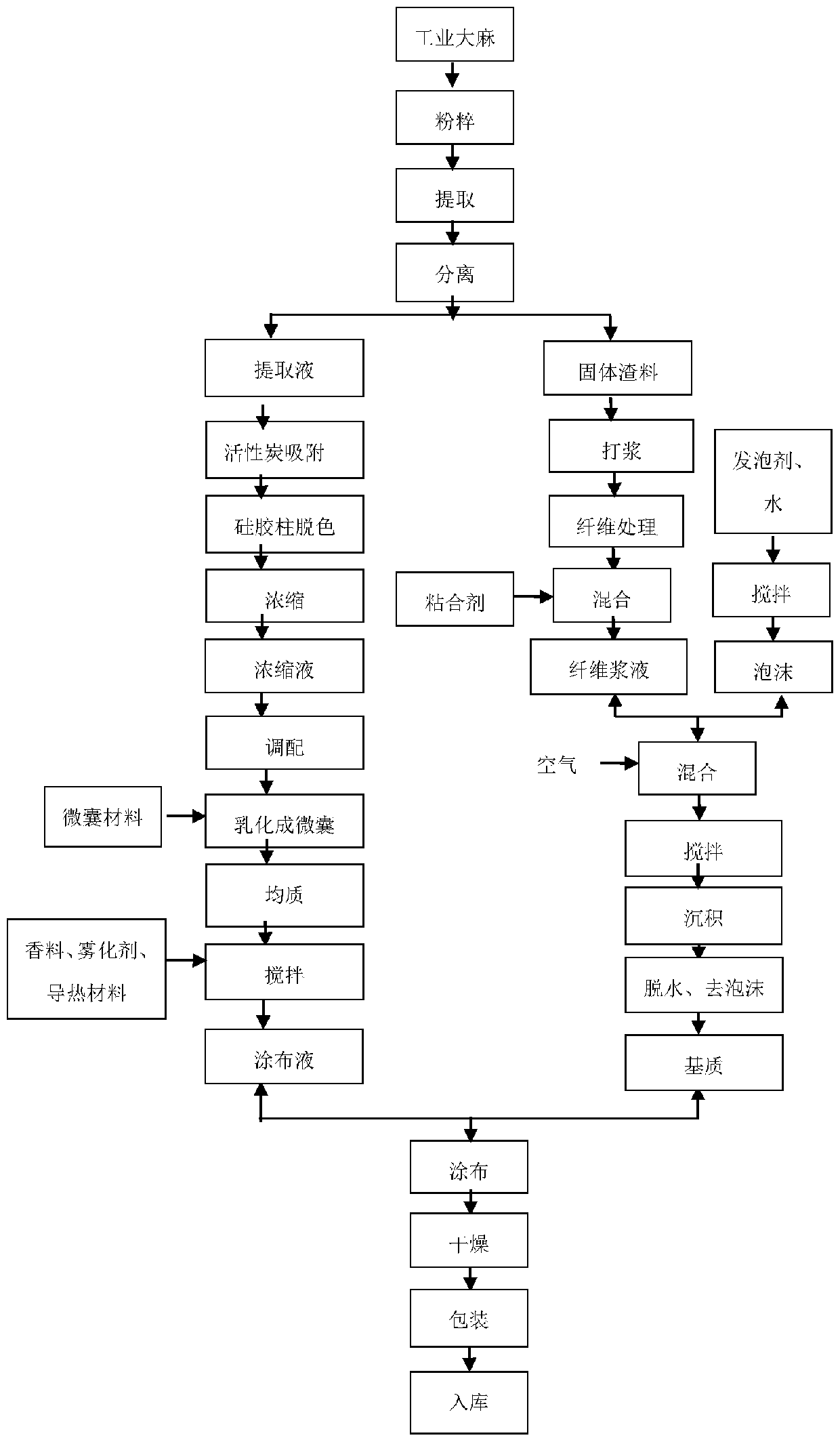

Method used

Image

Examples

Embodiment 1

[0200] The preparation of embodiment 1 tobacco products

[0201] Specifically include the following steps:

[0202] (1) Raw material preparation: Prepare raw materials according to mass percentage ratio: 40% of industrial hemp mosaic leaf raw materials (moisture content is 3-4%), 15% of atomizing agent, 3% of adhesive, 1.5% of spices, 0.5% of heat-conducting material %; foaming agent 0.04%; microcapsule material 3%, the balance is water.

[0203] (2) Extraction of raw materials: Mix the raw materials of industrial hemp flowers and leaves according to the ratio of leaves and pedicels in a ratio of 1:1, grind them into 20 meshes, add 50% ethanol to extract 3 times, each extraction time is 60 minutes, and obtain hemp flowers Leaf extract and solid residue;

[0204] (3) Separation: The extract of industrial hemp flowers and leaves is passed through a butterfly centrifuge, and the slag is separated. Among them, the extract is first adsorbed by granular activated carbon to remove ...

Embodiment 2

[0213] The preparation of embodiment 2 tobacco products

[0214] Specifically include the following steps:

[0215] (1) Raw material preparation: Prepare raw materials according to mass percentage ratio: 50% of industrial hemp mosaic leaf raw material (moisture content is 3-4%), 25% of atomizing agent, 5% of adhesive, 2.0% of spice, and 0.6% of heat-conducting material %; foaming agent 0.06%; microcapsule material 3%, the balance is water.

[0216] (2) Extraction of raw materials: Mix the raw materials of industrial hemp flowers and leaves according to the ratio of leaves and pedicels in a ratio of 1:1, grind them into 20 meshes, add 50% ethanol to extract 3 times, each extraction time is 60 minutes, and obtain hemp flowers Leaf extract and solid residue;

[0217] (3) Separation: The extract of industrial hemp flowers and leaves is passed through a butterfly centrifuge, and the slag is separated. The extract is first adsorbed by granular activated carbon to remove impurities...

Embodiment 3

[0226] The preparation of embodiment 3 tobacco products

[0227] Specifically include the following steps:

[0228] (1) Raw material preparation: Raw materials are prepared according to the proportion of mass percentage: 60% of industrial hemp mosaic leaf raw material (moisture content is 8-9%), 35% of atomizing agent, 10% of adhesive, 5% of spice, and 0.3% of heat-conducting material %; foaming agent 0.08%; microcapsule material 5%, the balance is water.

[0229] (2) Extraction of raw materials: Mix the raw materials of industrial hemp flowers and leaves according to the ratio of leaves and pedicels in a ratio of 1:1, grind them into 20 meshes, add 50% ethanol to extract 3 times, each extraction time is 60 minutes, and obtain hemp flowers Leaf extract and solid residue;

[0230] (3) Separation: The extract of industrial hemp flowers and leaves is passed through a butterfly centrifuge, and the slag is separated. The extract is first adsorbed by granular activated carbon to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com