Carrier element for pressure chamber of friction clutch

A friction clutch and bearing element technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of labor-intensive manufacturing, complex and expensive structure of friction clutches, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

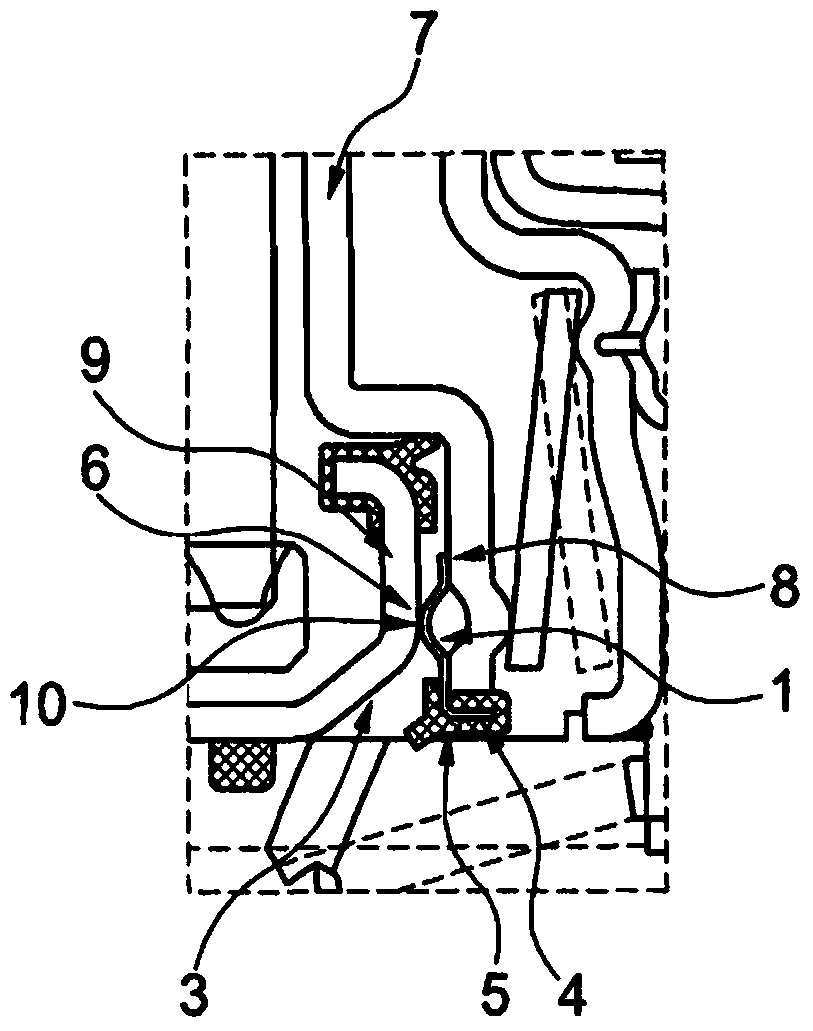

[0037] figure 1 Shown is a carrier element 1 which is arranged in a pressure chamber 3 of a friction clutch 2 (not shown here). The carrier element 1 has a stop element 6 which is embodied as a projection 10 and has a further stop 8 . The actuating element 7 of the friction clutch 2 is arranged in the smallest stop position in the pressure chamber 3 , so that the projection 10 of the stop element 6 bears against the part 9 , here the wall of the pressure chamber . The receiving element 4 has a sealing means 5 which is designed here as an axial slide element and seals off the pressure chamber 3 in an axially movable manner. The carrier element 1 is connected to the actuating element 7 via the receiving element 4 or indirectly via the sealing means 5 .

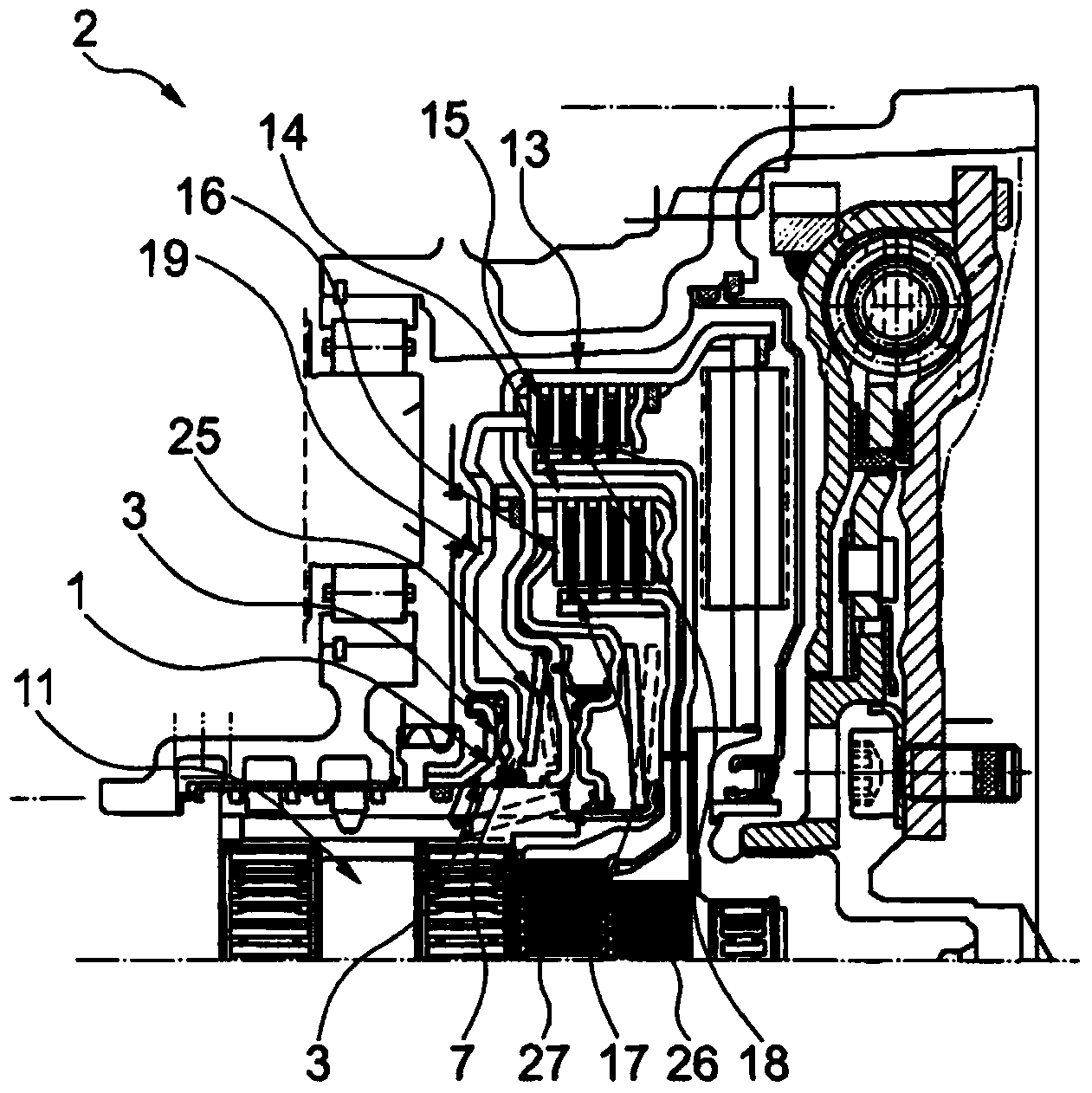

[0038] exist figure 2 The friction clutch 2 is shown in , which includes a first friction set 13 and a second friction set 14 , the friction sets include at least one first pressure plate 15 and a second pressure plate 16 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com