Preparation method for metallographic sample of zirconium and zirconium alloy microstructures

A metallographic sample and microstructure technology, applied in the field of materials, can solve the problems of operator's health hazard, discomfort observation and evaluation, sample size limitation, etc., to reduce equipment investment, improve sample preparation quality and speed, crystallinity grain clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

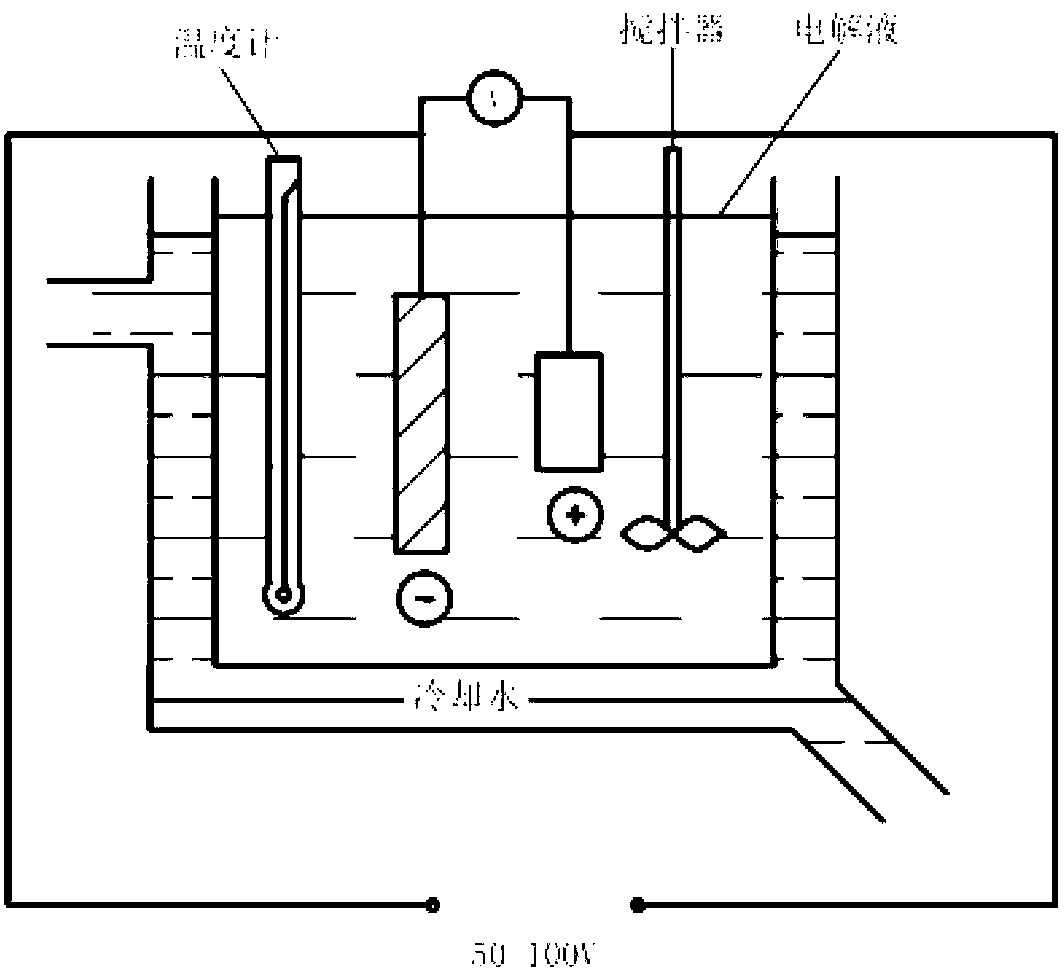

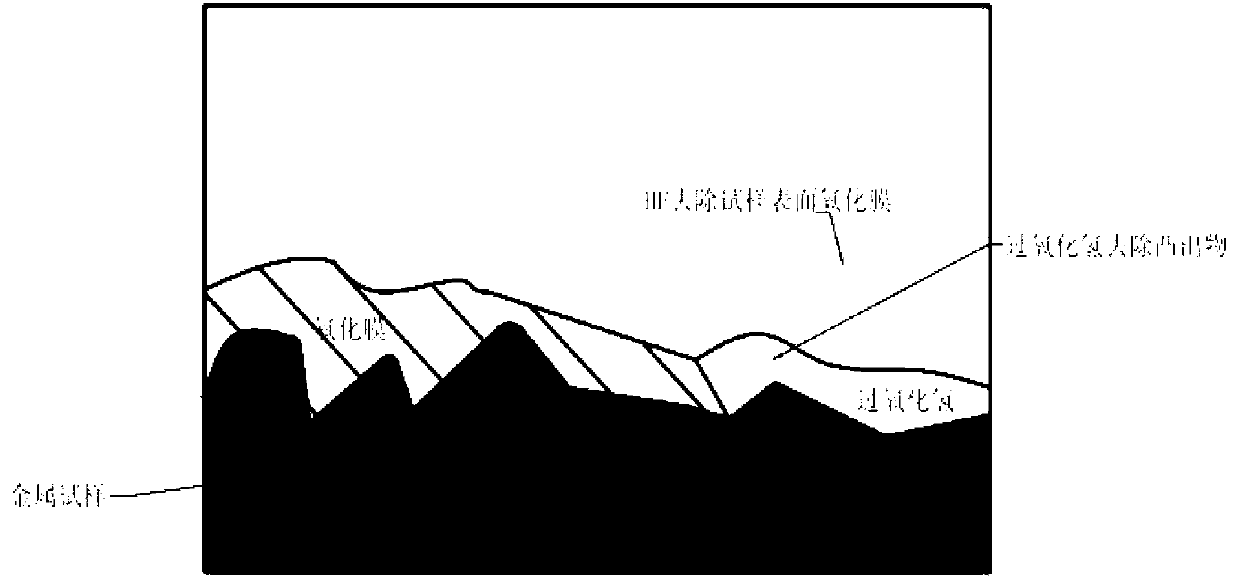

Method used

Image

Examples

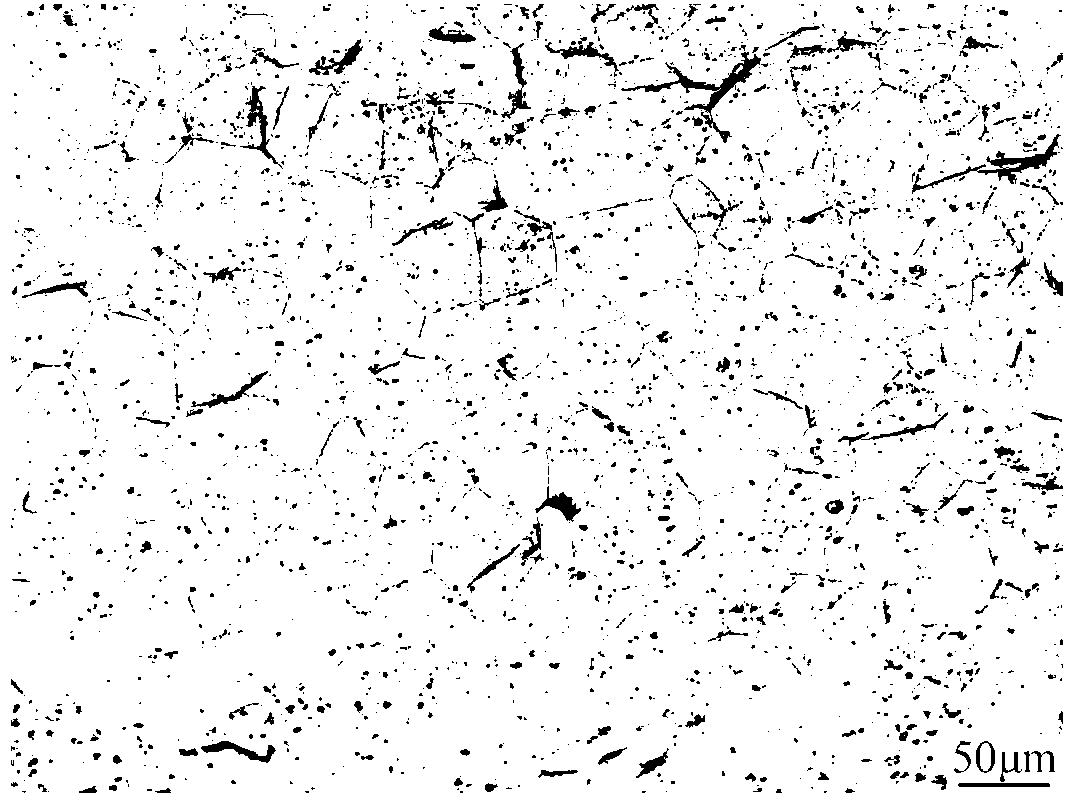

Embodiment 1

[0033] Prepare zirconium alloy metallographic samples according to the following preparation process and carry out microstructure observation, such as image 3 shown.

[0034] 1 Cleaning: Pre-clean the metallographic sample, remove the oil on the surface with acetone, and make the surface of the sample smooth;

[0035] 2 Pre-grinding: Pre-grind the sample on 240# metallographic sandpaper until the scratches on the sample face the same direction;

[0036] 3 Rough grinding: mechanically grind the sample on 400# metallographic sandpaper, the grinding direction is perpendicular to the grinding direction of step 2, until the scratch direction of the sample faces the same direction;

[0037] 4 Fine grinding: mechanically grind the sample on 600# metallographic sandpaper, the grinding direction is perpendicular to the grinding direction of step 3, until the scratch direction is in the same direction;

[0038] 5 Remove the film: configure the solution according to the following volu...

Embodiment 2

[0042] Prepare zirconium alloy metallographic samples according to the following preparation process and carry out microstructure observation, such as Figure 4 shown.

[0043] 1 Cleaning: Pre-clean the metallographic sample, remove the oil on the surface with acetone, and make the surface of the sample smooth;

[0044] 2 Pre-grinding: Pre-grind the sample on 240# metallographic sandpaper until the scratches on the sample face the same direction;

[0045] 3 Rough grinding: mechanically grind the sample on 400# metallographic sandpaper, the grinding direction is perpendicular to the grinding direction of step 2, until the scratch direction of the sample faces the same direction;

[0046] 4 Fine grinding: mechanically grind the sample on 600# metallographic sandpaper, the grinding direction is perpendicular to the grinding direction of step 3, until the scratch direction is in the same direction;

[0047] 5 Remove the film: configure the solution according to the following vol...

Embodiment 3

[0051] Prepare zirconium alloy metallographic samples according to the following preparation process and carry out microstructure observation, such as Figure 5 shown.

[0052] 1 Cleaning: Pre-clean the metallographic sample, remove the oil on the surface with acetone, and make the surface of the sample smooth;

[0053] 2 Pre-grinding: Pre-grind the sample on 240# metallographic sandpaper until the scratches on the sample face the same direction;

[0054] 3 Rough grinding: mechanically grind the sample on 400# metallographic sandpaper, the grinding direction is perpendicular to the grinding direction of step 2, until the scratch direction of the sample faces the same direction;

[0055] 4 Fine grinding: mechanically grind the sample on 600# metallographic sandpaper, the grinding direction is perpendicular to the grinding direction of step 3, until the scratch direction is in the same direction;

[0056] 5 Remove the film: configure the solution according to the following vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com