Method of surface oxidizing zirconium and zirconium alloys and resulting product

A technology of zirconium alloy and zirconia, applied in metal material coating process, shoulder joint, prosthesis, etc., can solve problems such as reducing integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

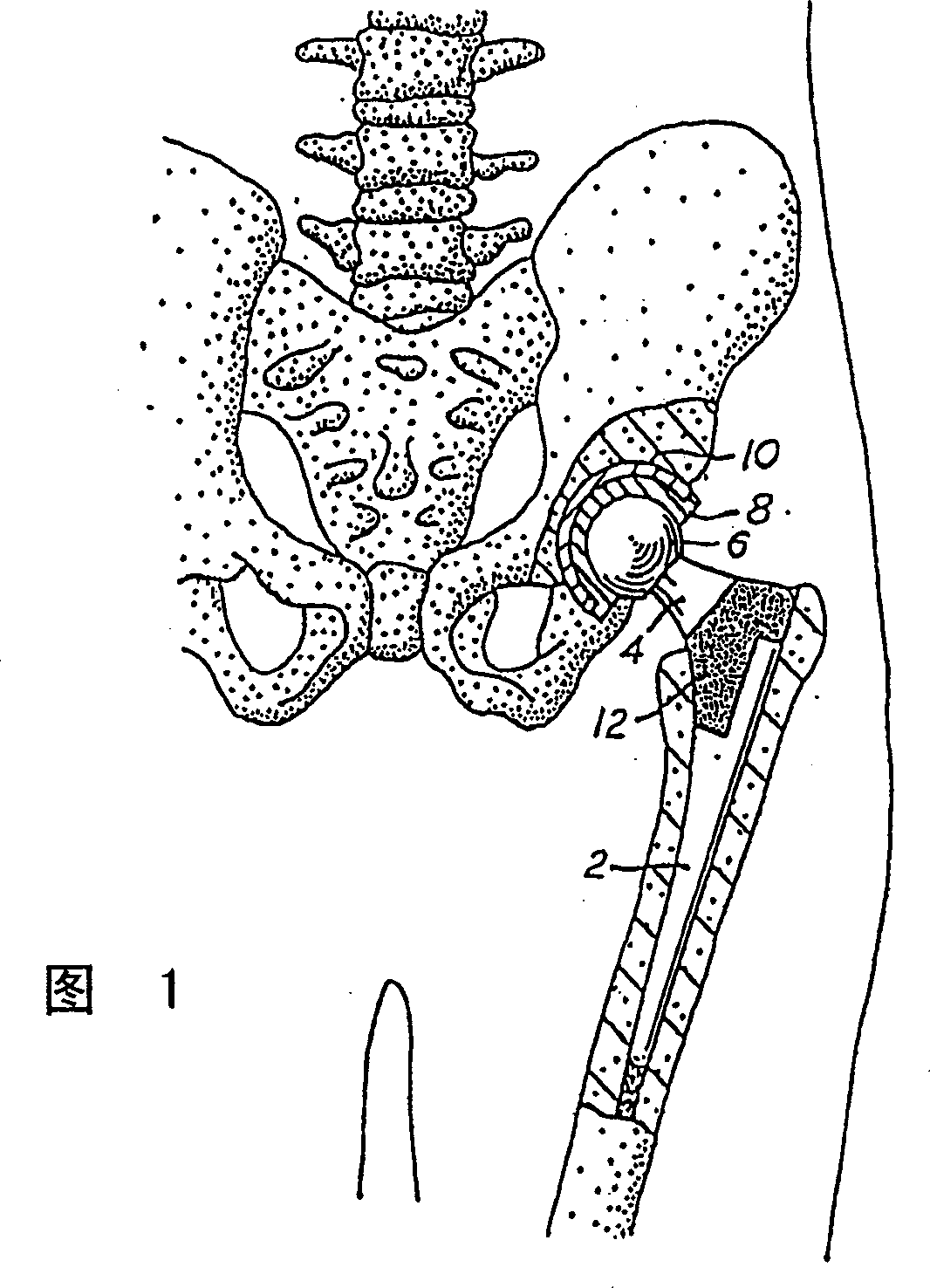

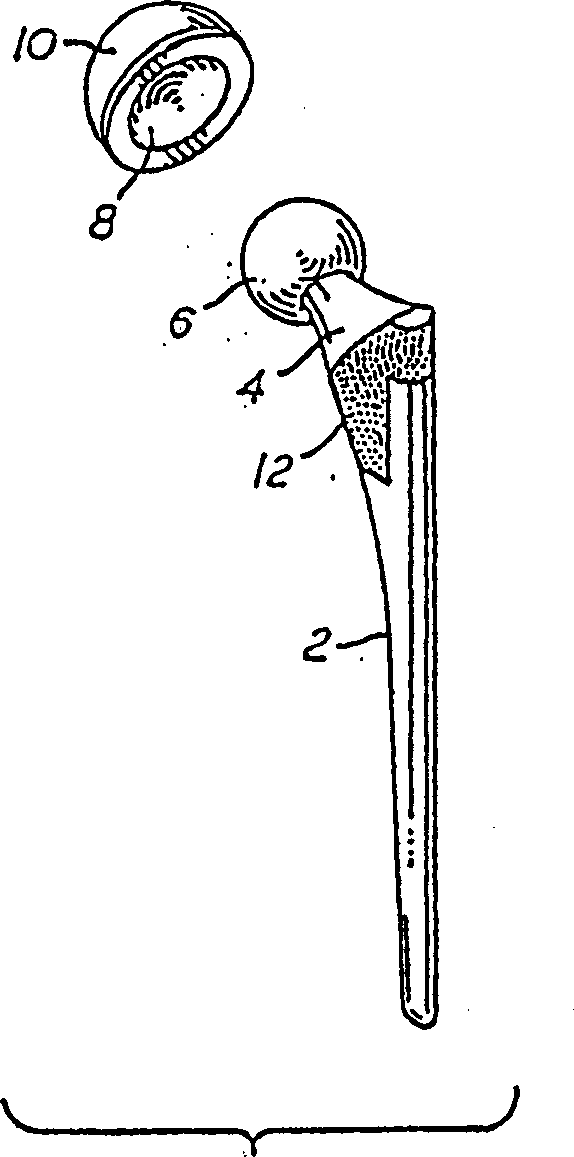

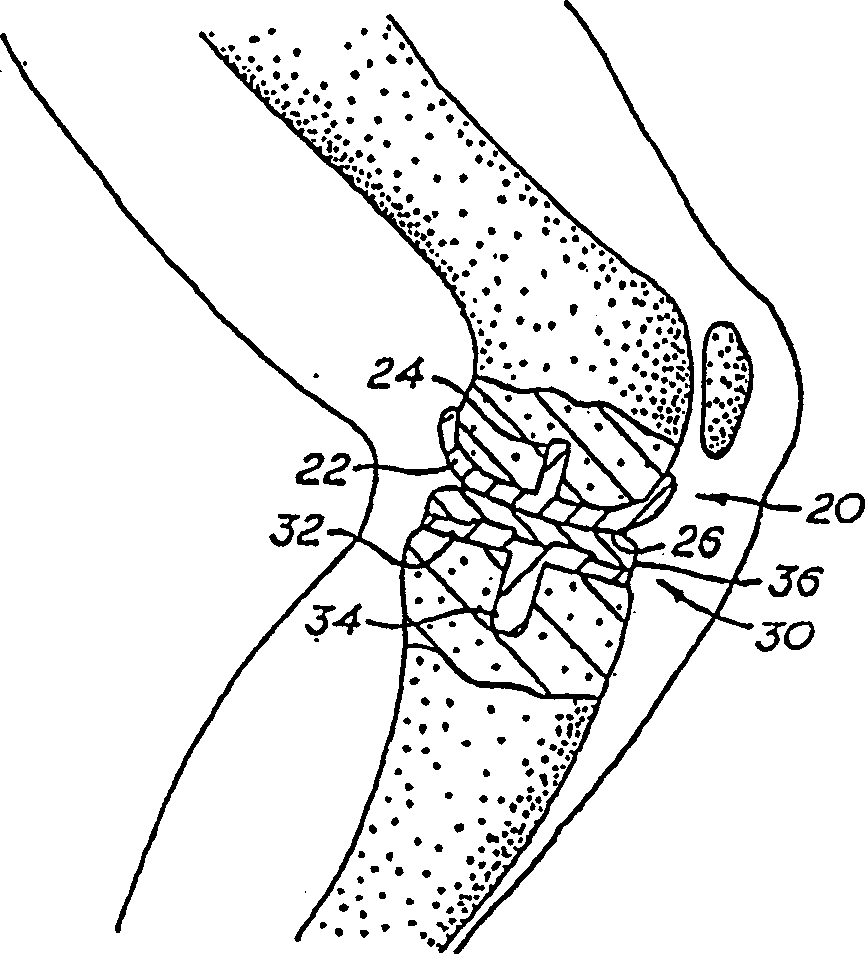

[0039] One aspect of the present invention is to provide a method for forming an oxide coating of uniform thickness on zirconium or zirconium alloys each having a single-phase crystal structure and uniform composition, and modified surface roughness Spend. Another aspect of the present invention is to provide a low friction, wear resistant uniform thickness on prosthetic surfaces such as articulating surfaces and irregular surface structures adapted to accommodate tissue ingrowth on a portion of the prosthetic body oxide coating.

[0040] Before oxidizing zirconia or zirconium alloys, the subject matter of the method of forming oxide coatings of uniform thickness can be applied to various Prosthetic components and devices. These prosthetic components and devices include, but are not limited to, cardiovascular implants, including heart valves, whole artificial heart implants, ventricular assist devices, vascular grafts, and endovascular supports; electrical signal-carrying de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com