Magnesium-zinc-lanthanon-zirconium magnesium alloy and method for preparing same

A magnesium-based alloy and rare earth technology, which is applied in the field of magnesium-zinc-rare-earth-zirconium magnesium-based alloys and their preparation, can solve the problems of insufficient selective utilization or alternative utilization of rare earth resources, not many varieties, etc., and achieves low gravity segregation. , The composition segregation is small, and the effect of meeting the market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

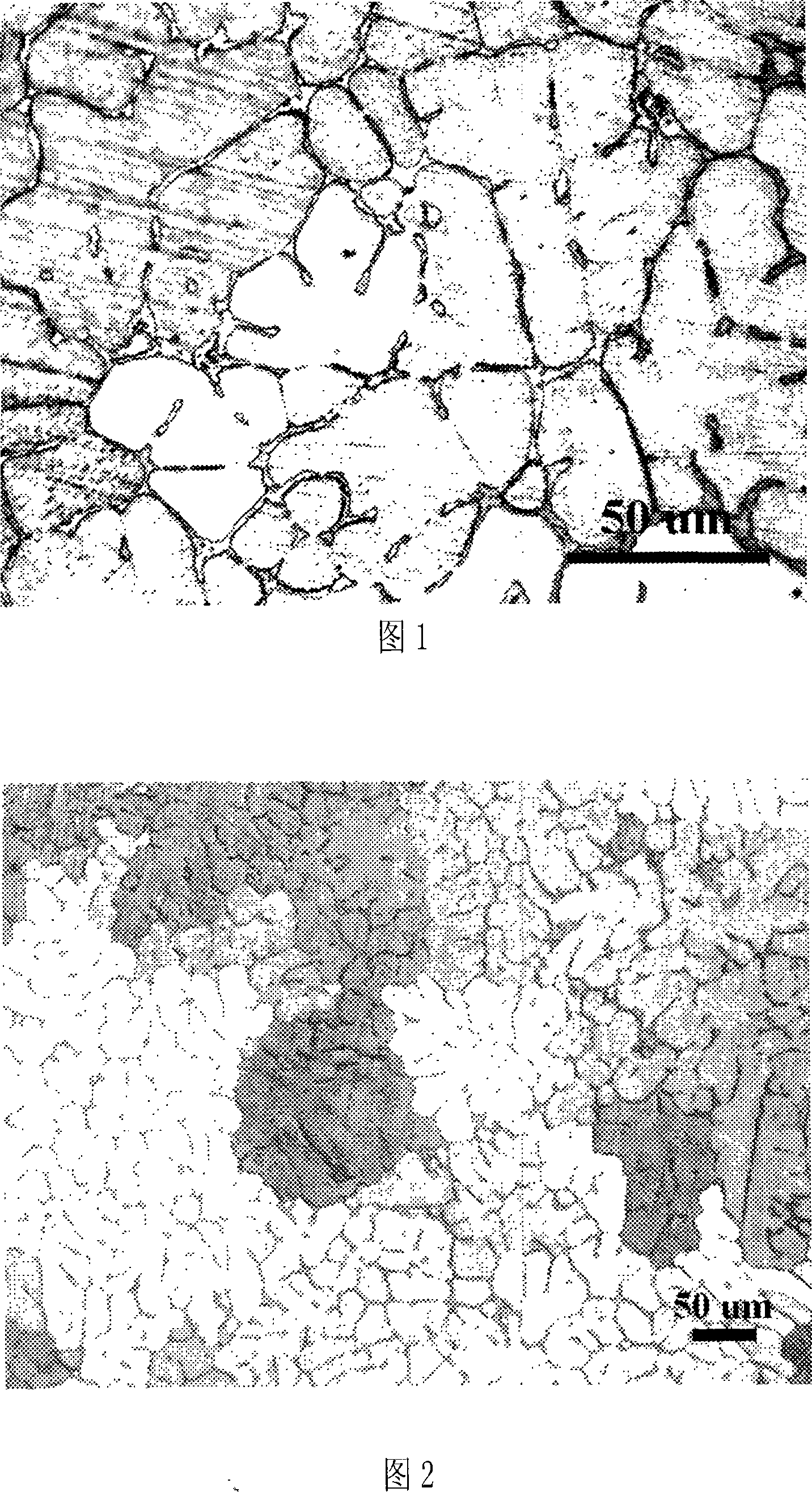

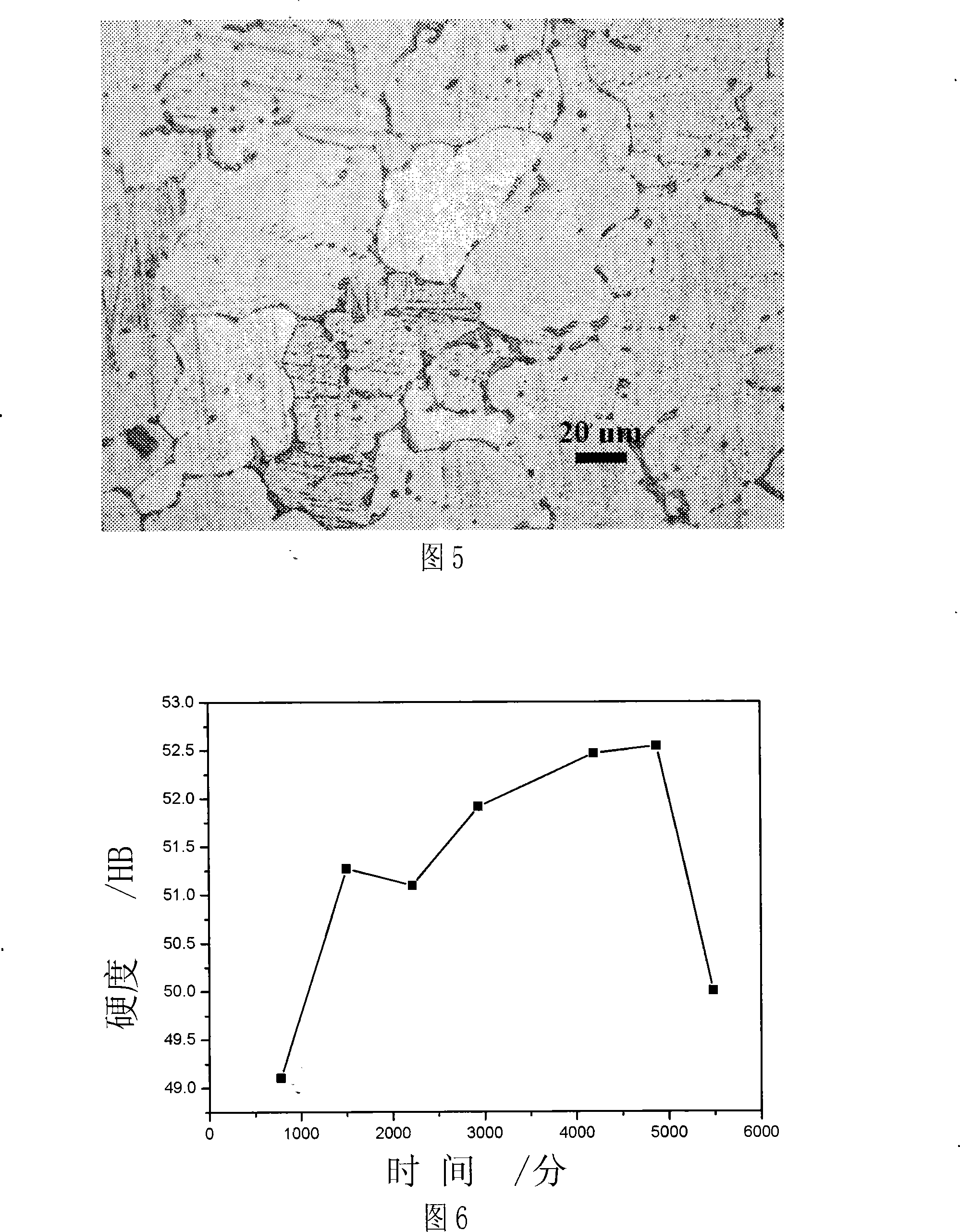

Embodiment 1

[0049] The batching is weighed according to the ratio of Mg-3wt%Zn-3wt%La-0.6wt%Zr. The steps and conditions are as follows: Mg ingot with a purity of 99.9%, Zn ingot with a purity of 99.98%, Mg-La, Mg-Ce, Mg-MC, Mg-MY, Mg-MM and Mg- Zr6 master alloy ingots are used as raw materials, and the rare earth or zirconium in the master alloy ingot accounts for 19.7wt% of La in the Mg-La master alloy, 22.7wt% of Ce in the Mg-Ce master alloy, and 22.7wt% of Mg in the master alloy. 19.71wt% of MC in the MC master alloy, 20wt% of MY in the Mg-MY master alloy, 35wt% of Zr in the Mg-Zr master alloy; the rest is Mg.

[0050] The raw materials of Mg ingot, Zn ingot and master alloy ingot are divided, degreased, dried and descaled to obtain bulk materials; according to the general formula Mg-3wt%Zn-3wt%RE-0.6wt%Zr, the ingredients are weighed; Alloy smelting is carried out in a gas-shielded resistance furnace. First, the graphite crucible is cleaned with molten salt with a weight ratio of KC...

Embodiment 2

[0055] The difference from Example 1 is that the Mg-3wt%Zn-3wt%La-0.6wt%Zr system is replaced by Mg-3wt%Zn-3wt%Ce-0.6wt%Zr; wherein Ce in the Mg-Ce master alloy accounts for 22.7wt% system; All the other operations are the same as in Example 1; the tensile strength (σ b ), yield strength (σ 0.2 ) and elongation (δ) are listed in Table 2.

[0056] Table 1: Main mechanical properties of Mg-3wt%Zn-3wt%Ce-0.6wt%Zr alloy in Example 2 at room temperature and high temperature

[0057] Alloy

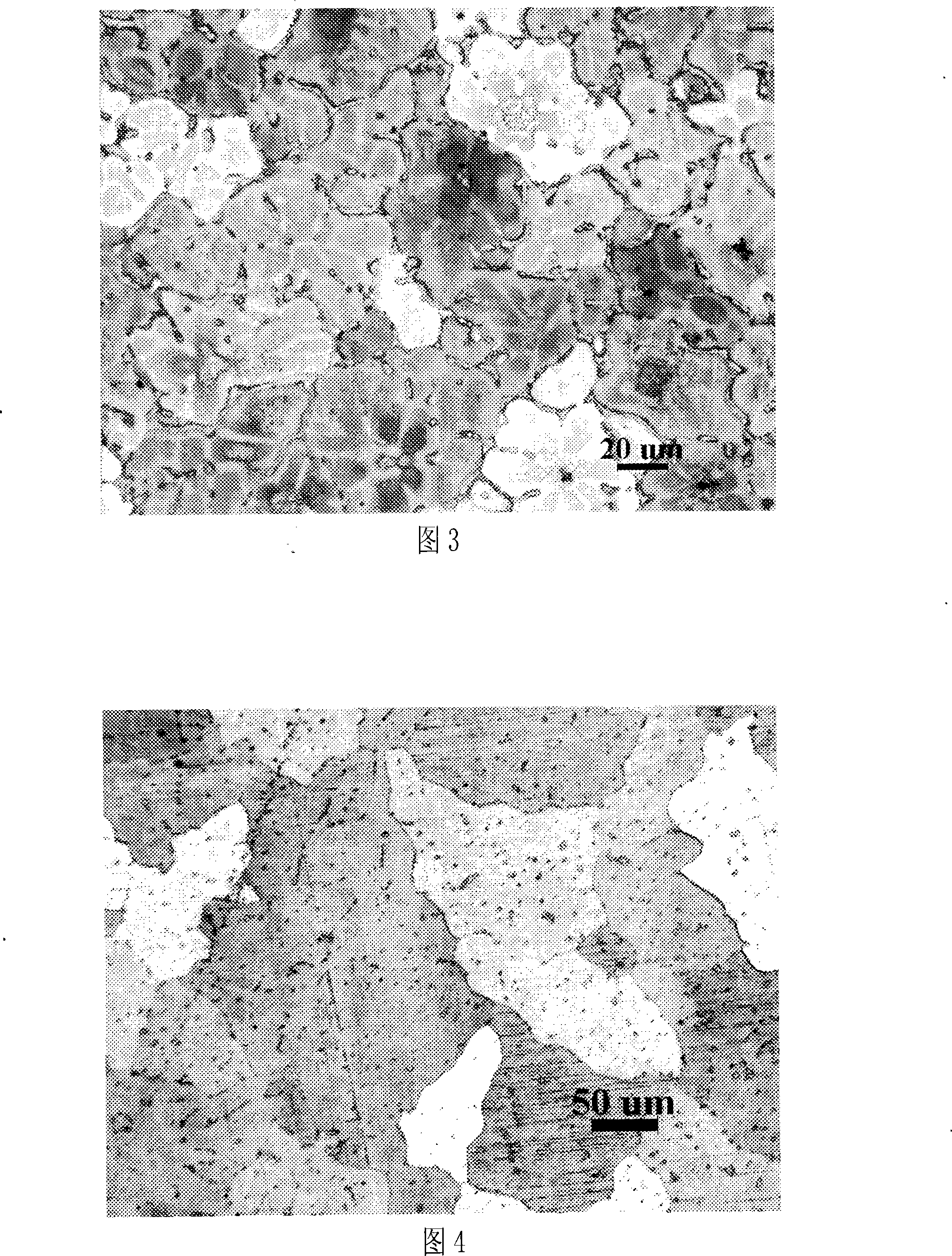

Embodiment 3

[0059] The difference from Example 1 Mg-3wt% Zn-3wt% MC-0.6wt% Zr is that the Mg-3wt% Zn-3wt% MC-0.6wt% Zr system is used to replace the Mg-3wt% Zn-3wt% La-0.6 wt% Zr system; wherein the MC in the Mg-MC master alloy accounts for 19.71wt%; the specific composition of cerium-rich rare earth MC is 60wt% Ce and 40wt% La, and the sum of the two weight percentages is 100%; the rest of the operations are the same as in Example 1 ; The tensile strength of the alloy at room temperature, 150°C and 200°C (σ b ), yield strength (σ 0.2 ) and elongation (δ) are listed in Table 3.

[0060] Table 3: Main mechanical properties of Mg-3wt%Zn-3wt%MC-0.6wt%Zr alloy in Example 3 at room temperature and high temperature

[0061] Alloy

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com