Preparation method and application for hypo eutectic aluminum-silicon alloy slab

A technology of aluminum-silicon alloy and aluminum-silicon intermediate alloy, which is applied in the field of preparation of hypoeutectic aluminum-silicon alloy slabs, can solve problems such as unfavorable mechanical properties, segregation, and coarse structure, so as to reduce production costs, overcome middle line segregation, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

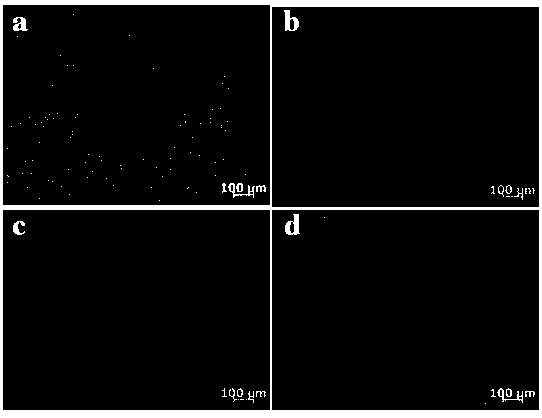

Image

Examples

Embodiment 1

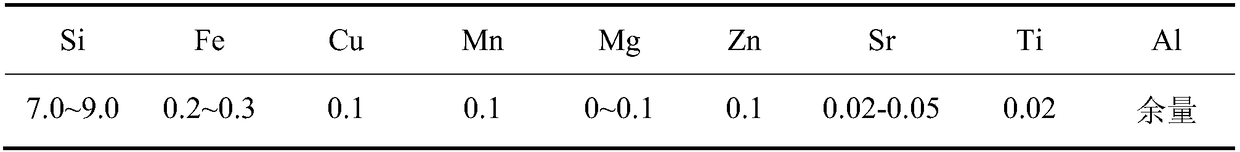

[0027] (1) The chemical composition of the hypoeutectic aluminum-silicon alloy cast-rolled slab of this embodiment is calculated by mass percentage, as shown in Table 2:

[0028] Table 2 The chemical composition table of the hypoeutectic aluminum-silicon alloy cast-rolled slab unit: %

[0029]

[0030] (2) Melting:

[0031] According to the composition of the aluminum alloy in the step (1), the furnace charge of the aluminum alloy smelting furnace satisfying the capacity of 20t is configured, and the chemical composition is in accordance with the adjusted chemical composition range of the 4343 aluminum alloy;

[0032] Add industrial aluminum ingot (99.70wt.%) and aluminum-silicon master alloy to the smelting furnace first, bury the aluminum-silicon master alloy in the middle of the aluminum ingot, heat and melt, and control the melting temperature at 720°C; The hydrogen content in the melt is controlled within 0.15mL / 100gAl; after the aluminum ingot is completely melted, s...

Embodiment 2

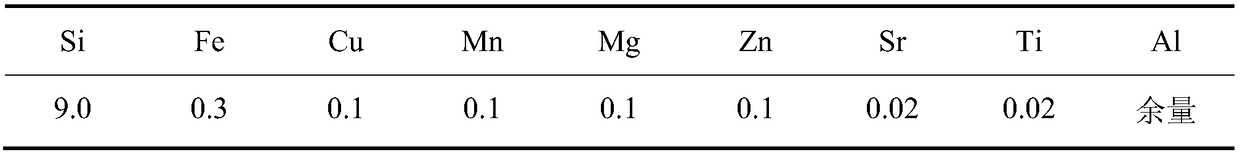

[0039] (1) The chemical composition of the hypoeutectic aluminum-silicon alloy cast-rolled slab of this embodiment is calculated by mass percentage, as shown in Table 3:

[0040] Table 3 The chemical composition table of the hypoeutectic aluminum-silicon alloy cast-rolled slab unit: %

[0041]

[0042] (2) Melting:

[0043]According to the composition of the aluminum alloy in the step (1), the furnace charge of the aluminum alloy smelting furnace satisfying the capacity of 20t is configured, and the chemical composition is in accordance with the adjusted chemical composition range of the 4343 aluminum alloy;

[0044] Add industrial aluminum ingot (99.70wt.%) and aluminum-silicon master alloy to the smelting furnace first, bury the aluminum-silicon master alloy in the middle of the aluminum ingot, heat and melt, and control the melting temperature at 750°C; The hydrogen content in the melt is controlled within 0.15mL / 100gAl; after the aluminum ingot is completely melted, st...

Embodiment 3

[0051] (1) The chemical composition of the hypoeutectic aluminum-silicon alloy cast-rolled slab of this embodiment is calculated by mass percentage, as shown in Table 4:

[0052] Table 4 The chemical composition table of the hypoeutectic aluminum-silicon alloy cast-rolled slab Unit: %

[0053]

[0054] (2) Melting:

[0055] According to the composition of the aluminum alloy in the step (1), the furnace charge of the aluminum alloy smelting furnace satisfying the capacity of 20t is configured, and the chemical composition is in accordance with the adjusted chemical composition range of the 4343 aluminum alloy;

[0056] Add industrial aluminum ingot (99.70wt.%) and aluminum-silicon master alloy to the smelting furnace first, bury the aluminum-silicon master alloy in the middle of the aluminum ingot, heat and melt, and the melting temperature is controlled at 780°C; The hydrogen content in the melt is controlled within 0.15mL / 100gAl; after the aluminum ingot is completely mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com