Casting equipment and method using solid-liquid two-phase region temperature as casting mold temperature

A technology of mold temperature and casting equipment, which is applied in the field of casting equipment at the temperature of the solid-liquid two-phase region, can solve the problems of difficulty in casting metals with a wide solid-liquid two-phase region, low production efficiency, and problems with the smoothness and quality of the surface of the billet. Poor performance and other problems, to achieve the effect of compact structure, improved product quality, and excellent plastic processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

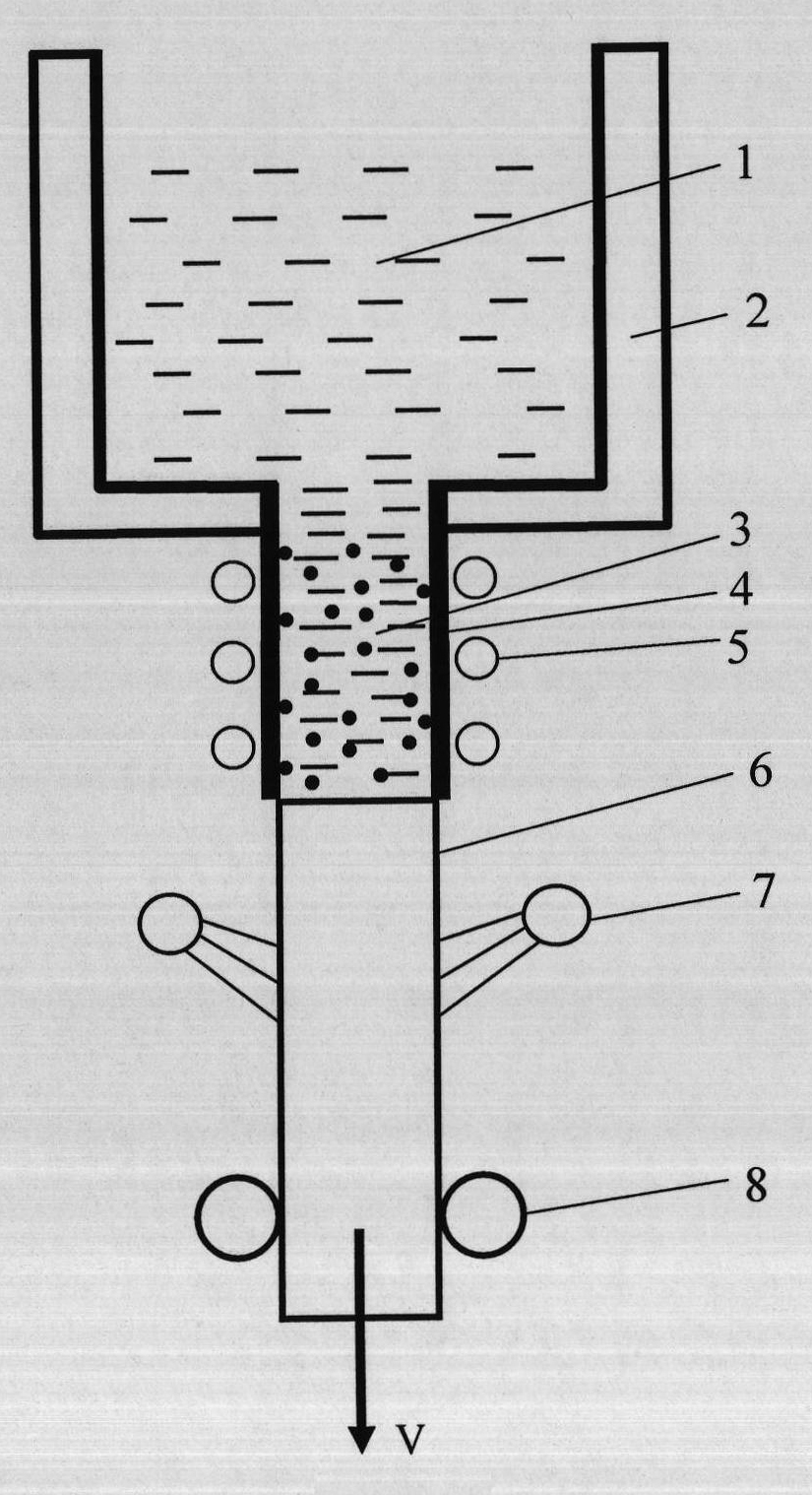

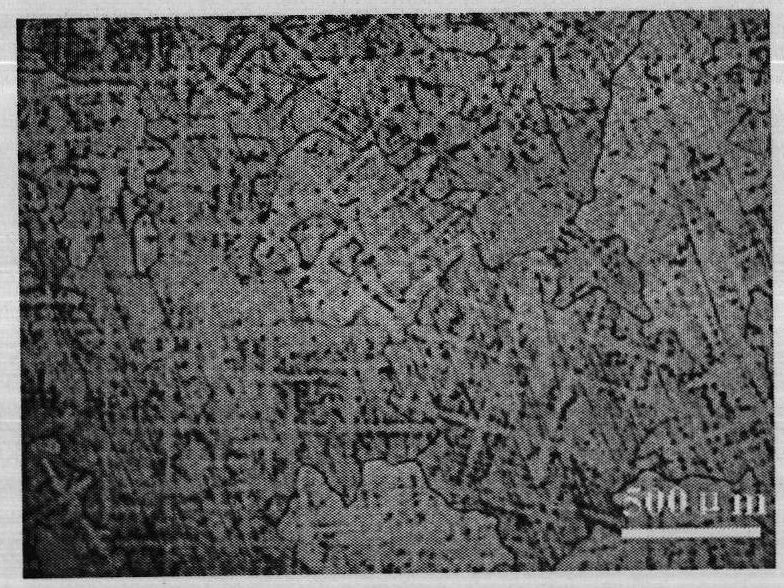

[0022] QSn6.5-0.1 tin-bronze wire with a diameter of 10mm was formed by continuous casting in two-phase zone. QSn6.5-0.1 tin bronze melt (1) flows into the mold (4) in the two-phase region from the crucible (2); adjust the power of the induction heater (5), and control the temperature of the mold to 940 ° C. Obtain QSn6.5-0.1 tin bronze solid-liquid mixture (3); cooler (7) adopts the cooling water that temperature is 25 ℃, flow rate is 1700L / h to carry out forced cooling to QSn6.5-0.1 tin bronze; traction mechanism ( 8) Continuous drawing at a drawing speed of 90 mm / min to obtain a QSn6.5-0.1 tin bronze wire (6). The prepared QSn6.5-0.1 tin bronze wire has good surface finish, relatively uniform distribution of chemical components, and dense internal structure. There are fine grains in some columnar grain boundaries, a large number of columnar grains contain one or several other grains, and some grain boundaries are obviously zigzag.

Embodiment 2

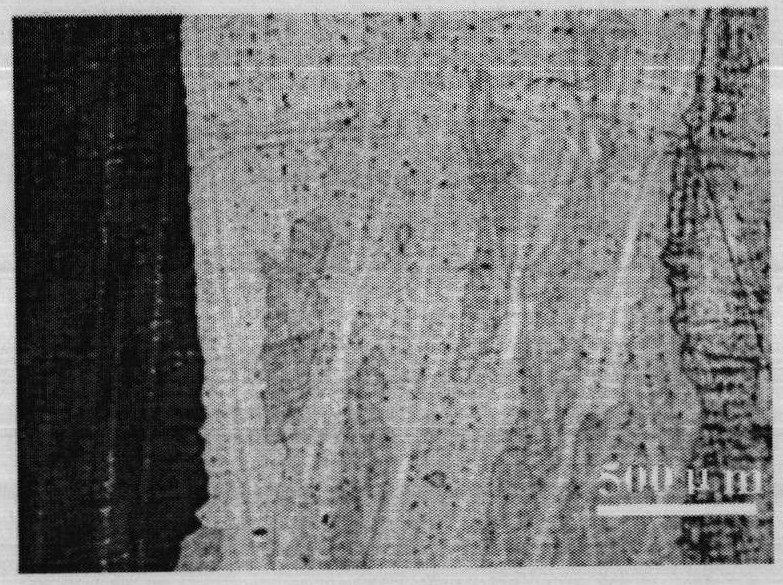

[0024] The QSn6.5-0.1 tin bronze pipe with an outer diameter of 12mm and a wall thickness of 2mm is cast in the two-phase zone. QSn6.5-0.1 tin bronze melt (1) flows into the two-phase region mold (4) from the crucible (2); adjust the power of the induction heater (5) to control the mold temperature to 1020°C, Obtain QSn6.5-0.1 tin bronze solid-liquid mixture (3); Cooler (7) adopts the cooling water that temperature is 15 ℃, flow rate is 900L / h to carry out forced cooling to QSn6.5-0.1 tin bronze; Traction mechanism ( 8) Continuous drawing at a drawing speed of 200 mm / min to obtain a QSn6.5-0.1 tin bronze pipe (6). The prepared QSn6.5-0.1 tin bronze pipe has good internal and external surface smoothness, relatively uniform distribution of chemical components, and dense internal structure. Composed of columnar grains, and some columnar grain boundaries have fine grains, a large number of columnar grains contain one or several other grains, and some grain boundaries are obviousl...

Embodiment 3

[0026]A QSn6.5-0.1 tin bronze plate with a width of 25mm and a thickness of 5mm was formed by semi-continuous casting in the two-phase region. QSn6.5-0.1 tin bronze melt (1) flows into the two-phase zone mold (4) from the crucible (2); adjust the power of the induction heater (5) to control the mold temperature to 980°C, Obtain QSn6.5-0.1 tin bronze solid-liquid mixture (3); cooler (7) adopts the cooling water that temperature is 20 ℃, flow rate is 1300L / h to carry out forced cooling to QSn6.5-0.1 tin bronze; traction mechanism ( 8) Continuous drawing at a drawing speed of 150 mm / min to obtain a QSn6.5-0.1 tin bronze sheet (6). The prepared QSn6.5-0.1 tin bronze plate has good surface finish, relatively uniform distribution of chemical components, and dense internal structure. There are fine grains in some columnar grain boundaries, a large number of columnar grains contain one or several other grains, and some grain boundaries are obviously zigzag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com