Hard impact-resistant polyvinyl chloride composition and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied in the field of rigid impact-resistant PVC composition and its preparation, can solve the problems of high requirements for control conditions, no obvious improvement in the plasticizing processing performance of polyvinyl chloride, complicated process and the like , to achieve the effect of simple preparation method, good impact resistance and good plasticizing processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

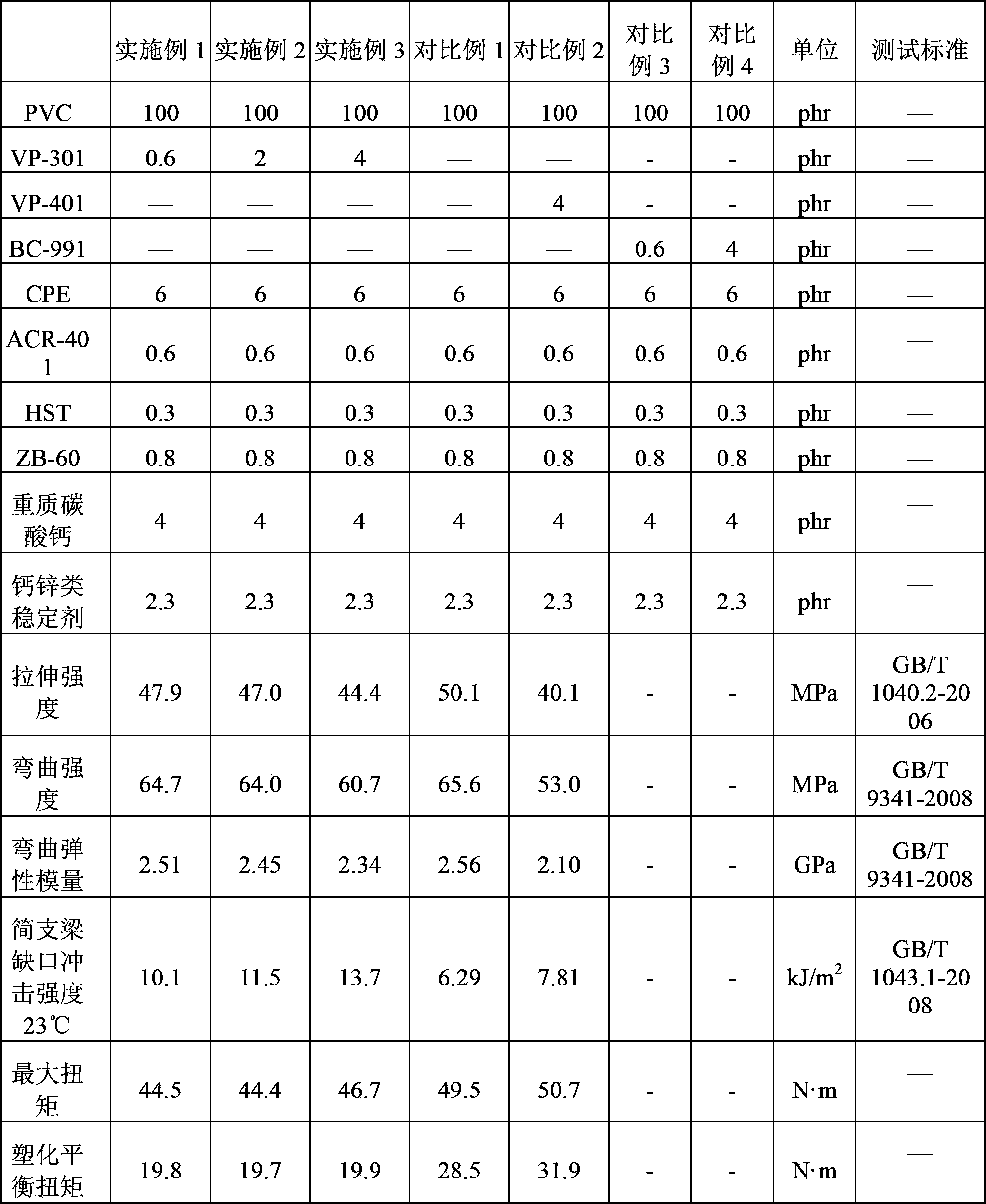

Examples

Embodiment 1~3

[0026] Fully vulcanized powdered acrylate rubber (prepared by Sinopec Beijing Research Institute of Chemical Industry, brand VP-301, with an average particle size of 100 nm and a gel content of 87%; acrylate emulsion produced by Beijing Dongfang Yakeli Chemical Technology Co., Ltd., brand BC -991, add cross-linking aid trimethylolpropane triacrylate according to the mass ratio of emulsion dry rubber, and then irradiate and vulcanize the rubber powder obtained by spray drying), polyvinyl chloride resin (Sinopec Qilu Branch, brand QS-1050P, The average degree of polymerization is 1000-1100) 100 parts, calcium zinc stabilizer (Dalian Kaimisen Chemical Products Co., Ltd., brand PRD5515) 2.3 parts, polyol fatty acid ester PVC lubricant (Zibo Huaxing Auxiliary Co., Ltd., brand ZB-60 ) 0.8 parts, stearic acid (HST, Indonesia Chemical Company) 0.3 parts, processing aids (Jihua Group Suzhou Anli Chemical Co., Ltd., brand ACR-401) 0.6 parts, heavy calcium carbonate (Nanjing Omiya Fine Ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com