Preparation method of hyaluronic acid modified superparamagnetic iron oxide/gold composite nanoprobe

A hyaluronic acid modification and superparamagnetic technology, which is applied in the preparation of preparations for in vivo experiments, pharmaceutical formulations, X-ray contrast agents, etc., can solve the problem of not finding superparamagnetic iron oxide/gold nanocomposite probes, etc. , to achieve good colloidal stability, good biocompatibility, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 5.4mL HAuCl 4 4H 2 O solution (30mg / mL) was added to 50mL PEI (100mg) aqueous solution, stirred for 30 minutes; then, 0.9mL NaBH treated with ice bath was added to the mixture 4 (45.4mg) solution (ethanol / ultrapure water, v / v=1:2), continue to stir in ice bath for 1-2h; ), freeze-dried to obtain Au-PEI nanoparticle powder, which was stored at -20°C for future use.

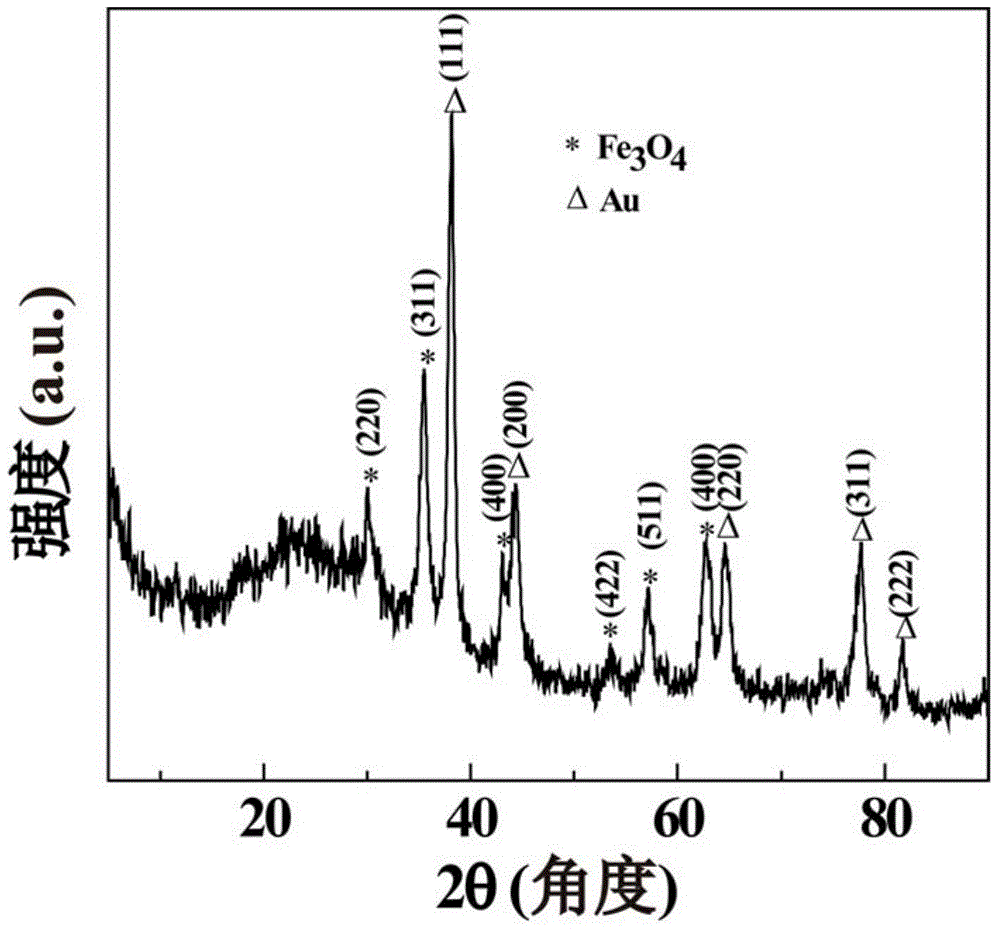

[0069] Dissolve the Au-PEI powder prepared above in 10 mL of water, then add to 10 mL of FeCl 2 4H 2 O (0.089g) and FeCl 3 ·6H 2 In the aqueous solution mixed with O (0.157g), heat and stir at 50°C for 3-5 minutes to fully dissolve it; then, add 5mL NaOH (1.0g) aqueous solution dropwise to the mixed solution, and stir at 80°C for 30 minutes; React at room temperature for 1-2 hours; after the reaction, the product is magnetically separated, washed and purified to obtain PEI-modified Fe 3 o 4 / Au nanoparticles, stored at 4°C for later use; 3mL nanoparticle solution was taken, vacuum freeze-dried for X-...

Embodiment 2

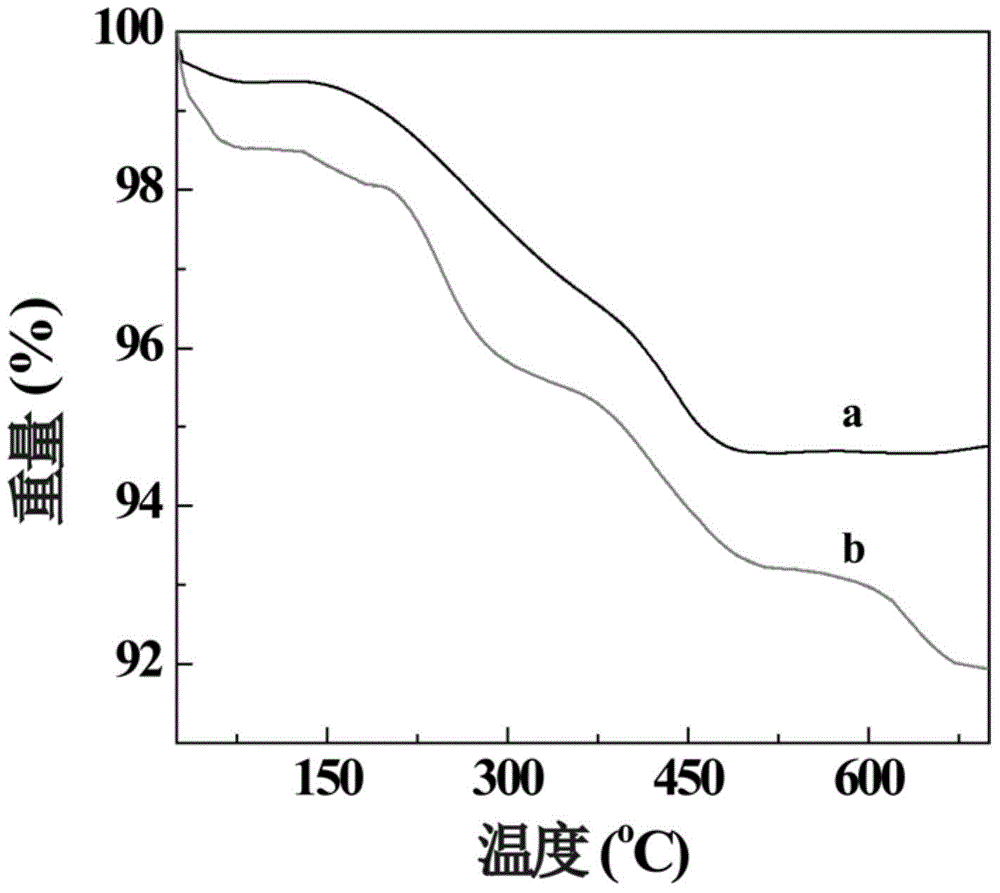

[0071] With the 10mL Fe in embodiment 1 3 o 4 / Au-PEI (25mg) aqueous solution was magnetically separated and dispersed into 10mL DMSO solution; then HA (Mw=5808, 9mg) was dissolved in 5mL of water at 70°C, and 5mL containing EDC (2.98mg) and NHS (1.79 mg) in DMSO solution, stir and activate for 2-4h; then add the activated HA to the above Fe 3 o 4 / Au-PEI in DMSO solution, stirred for 2 to 4 days, magnetically separated, washed and dispersed in water to obtain Fe 3 o 4 / Au-HA composite nanoprobes. Take 3mL nanoparticle solution, vacuum freeze-dry for thermogravimetric analysis. The TGA results show that the HA upload is about 2.81% (see attached figure 2 ).

Embodiment 3

[0073] Get the Fe prepared by the present invention 3 o 4 / Au-PEI (Example 1) and Fe 3 o 4 / Au-HA (Example 2) suspension 100 μL, respectively prepared 1.5 mL aqueous solution with ultrapure water for measuring surface potential and hydrodynamic diameter (see attached table 1). The potential results showed that the surface potentials of nanoparticles before and after HA modification were +36.1mV and -19.6mV, and the hydrodynamic particle sizes dispersed in water were 339.3nm and 342.2nm, respectively.

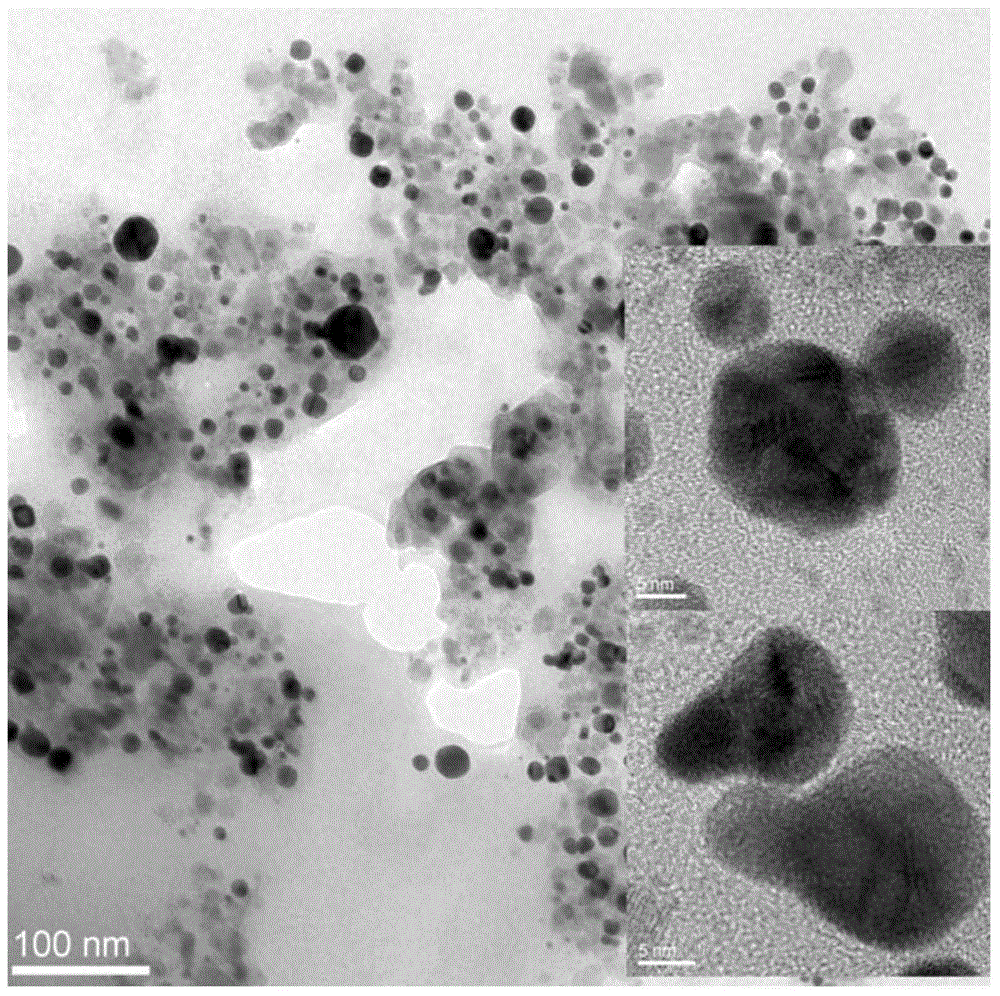

[0074] Get the Fe prepared by the present invention 3 o 4 5 μL of each aqueous solution of Au-HA composite nanoprobe (Example 2), and then prepare 100 μL of nanoparticle suspensions with ultrapure water. And take 5 μL of nanoparticle suspension and drop it on the surface of the copper grid, dry it in the air and use it for TEM test (see attached image 3 ). The TEM test results show that the morphology of the ferric oxide nanoparticles in the composite nanoparticles is sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com